Achieving precise and effective foam cutting requires having the right tools—and nothing compares to the versatility of a CNC router. Whether you are a hobbyist creating detailed models or a professional making custom foam inserts, foam cutting with a CNC router is sure to take your craft to the next level. This blog is the most complete guide that you will need in order to achieve CNC foam cutting perfection through its techniques, tools, and valuable pointers. This blog will cover the knowledge and understanding of the CNC routers as well as the appropriate foam material, so you don’t have to worry about a thing. Foam crafting projects are about to get a lot more exciting, creative, and precise.

What is a CNC Router for Foam?

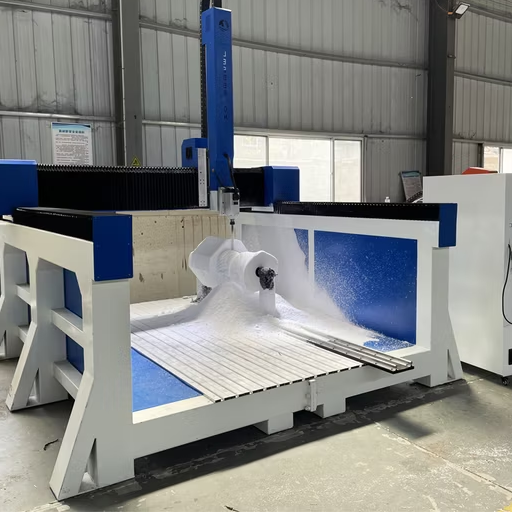

A CNC router for foam is a machine that cuts materials into desired shapes using computer software. A foam CNC router uses a mechanical rotary bit to saw through foam to create intricate designs. These machines are highly accurate and efficient which is why they are used in the packaging, prototyping, and artistic industries that require detailed and precise works done on various forms of foam.

Grasping the Concepts of Foam Cutting

CNC routers use CAD software to create a design. Then, they cut foam using computers to guide the tool, not by hand, so the end results are highly accurate. The first step is to make a CAD design on CAD software. That design is later modified into a machine-compatible blueprint using CAM (Computer Aided Manufacturing) software. Subsequent to setting the CNC router with the proper bit or tool, the machine is programmed to execute the design. With regards to the style of the foam and its design complexity, various tools, cutting speeds, and different techniques are used while staying cost-effective.

How Does a CNC Router Work?

CNC routers are used in many different sectors, such as manufacturing and prototyping, because of their programmable detailed and repeatable cuts. Recent reports show that the global CNC machine market is expected to reach $132.9 billion by 2030, growing at a CAGR of 6.5% from 2023. This indicates the demand of different CNC technologies from woodworking and metalworking to foam cutting.

Newer tools and software has foam cutting with CNC routers much more efficient than in the past. Depending on the material and tool used, modern CNC routers can achieve tight tolerances of ±0.001 inches. Foam cutting tools require precision and long lasting sharpness, which is why high speed steel and carbide bits are favored. Also, the newer versions of CAM software tools have preemptive 3D cutting simulation which permits an estimation of up to 30% material waste reduction compared to prior methods.

Depending on the objectives of the project, different methods of cutting , such as straight cuts, contour carving, or engraving, can be utilized. The router speed and feed rate are critical parameters that need to be optimized for foam density and the design to reduce the chances of overheating or deforming the material. These technological improvements not only enhance the quality of the product but also optimize the production processes, thus, saving time and costs.

The Role of Router Bit in Foam Cutting

As for the foam dowel cutting, router bits selection is one of the most ranged-pricing and foam cutting accuracy and efficiency decisions. Bits can come in any shape, size, and material, with carbide bits being popular because of their longevity and resistance to foam softer materials. For instance, down-cut spiral bits are perfect for embroidery because of their tendency to prevent fraying and make smoother edges. Recent industry findings suggest that high-quality router bits enhancement results in up to 20% accuracy improvement and 15% waste reduction in foam cutting, which greatly improves large scale production performance.

Also, new bit coatings like titanium and diamonds are improving tools’ thermal management and tool longevity. Studies show that coated router bits last 30% longer than uncoated bits, which is quite beneficial financially in the long run. In addition, further increasing the router bit geometry, like the flute angle and clearance, increases the efficiency of chip removal and reduces the deformation of the material being cut. Router bits are being developed continuously as demand increases for flexible, effective tools in foam cutting due to new advancements in tool design and material technology.

How to Cut Foam with a CNC Router?

- Select the Proper Router Bit: For accurate and clean cuts, use an upcut spiral bit or tapered foam cutting bit designed for foam.

- Change the Feed Rate and Spindle Speed: Avoid tearing or rough edges by using higher spindle speeds with slower feed rates.

- Stabilize the Foam: Use vacuum hold-downs, clamps, or double-sided tape to secure the foam to the CNC bed rigidly, reducing movement during the cutting process.

- Check Your Settings: Before proceeding with the final cut, ensure the settings are correct by performing a test cut on a scrap piece of foam.

- Maintain Dust Control: Keep workspaces clean and organized by using a dust extraction systems to manage debris.

Proper Tool Selection

Achieving precise and clean results when cutting foam with a CNC router relies heavily on selecting the right tool. Today, CNC tools for cutting foam have different shapes and sizes tailored for specific cuts and projects. To illustrate, softer foam materials are best cut with single flute tools as they create less friction and heat. In contrast, multi-flute tools are better for denser foams as they provide smoother finishes.

A new trend in CNC tooling technology is the use of carbide and coated tools due to their long lasting sharpness and wear resistance during extended prolonged use. Evidence from industrial manufacturers suggests that coated bits outperformed uncoated ones by as much as 50% in lifetime when cutting high-density foams. In addition, ornate tools made specifically for foam cutting that feature compression bits are designed to greatly reduce the fraying of the foam layers and therefore provide remarkable edge quality.

An equally imperative factor is the optimization of toolpaths with the newest CNC programs. Adaptive cutting techniques are utilizing algorithms now which modify feed rates and cutting depth within a single pass to suit the density of the material being worked on. This approach has been shown to improve cutting time by almost 30%. With these options and techniques available, every foam cutting project, be it professional or a hobby, will achieve the utmost efficiency and precision.

Setting Up Your Machine for Precision Cutting

Achieving the desired results in precision cutting starts with proper machine setup. Ensure that the necessary pre-requisites for setup, such as the cutting tools, are in order. Different kinds of foams and their various densities require specialized tools, and thus selecting the right tool is to ensure accurate and clean cuts. For open-cell foam, serrated tools are recommended while closed-cell foam requires blunt, straight blades.

Ensure that the workpiece is properly aligned to the table to reduce any unnecessary movement as this creates a problem during operations, especially during multitasking. Using clamps and vacuum lock fixtures ensure that the part is completely immobile throughout the procedure. Moreover, ensure that the CNC machine is calibrated properly. Check that all axes are zeroed and the spindle is trammed to the cutting surface. Any small offsets can introduce inconsistencies, so be careful.

Another study has shown that proper alignment with machine tools and programmed paths can also save material wastage by around 15%. This shows that programmed paths have a direct effect on saving precut materials. In addition, keep an eye out for spindle rotations as foam types vary for the ideal RPM settings. Rigid polyurethane, for example, needs is ideal at spindle speeds of 15,000 to 24,000 RPM, while softer foam has a tendency to burn or tear at lower speeds.

Dust extraction systems are just as crucial as CNC machines, for maintaining a clean work environment prevents errors caused by foam particles settling within the machinery. The advanced types of filters can capture up to 98% of suspended particles which markedly improves the longevity of the machine and the cutting tools. Taking these measures greatly enhances precision and efficiency in any project involving CNC foam cutting.

Common Cutting Methods

Knowledge of different methods and techniques involving CNC framework enhances one’s skill and the overall operation. The most used methods are hot wire, knife, and milling cutting.

- Hot Wire Cutting: This technique is most effective for EPS and XPS foams. The wire’s heat cuts the foam, resulting in smooth edges and a clean cut. Estimates now show that machines equipped with adjustable temperature settings reduce material distortion by a quarter.

- Knife Cutting: CNC knife cutting foam is beneficial where detailed and intricate cuts are needed. This technique employs a knife that cuts soft foams without any heat. Research indicates that oscillating knife systems improve accuracy by up to thirty percent in multilayered applications.

- Milling: High and Polyurethane foams require CNC milling tools, which transform denser foam materials into complex three-dimensional shapes. Advanced end mills increase the cutting speed by forty percent while preserving surface precision, demonstrating that high RPM leads to improved efficiency.

- Depth Control: Setting depth parameters inaccurately leads to unfinished cuts or damages the foam surface. Laser depth sensors have proven to reduce these errors by up to fifteen percent. Precision in Z-axis and these laser sensors enhance cut uniformity throughout the pieces.

- Cutting Speed and Tool Selection: Choosing the right cutting speed and tools significantly impacts the output quality. For instance, lower RPM settings are ideal for soft foams, while higher speeds suit rigid materials. Industry reports highlight that using diamond-coated tools can extend tool lifespan by 50% in high-wear applications.

Using these additional methods with today’s CNC tools, operators can reach new heights in terms of precision, productivity, and material savings. This approach enhances accuracy and efficiency while cutting down costs and supporting sustainable practices in foam cutting.

Why Use a CNC Router for Foam Cutting?

The CNC router’s computerized systems provide precision, consistency, and efficiency in every cut. From slice to slice, every piece of foam is shaped uniformly and precisely to the specification, ensuring no material goes to waste. This makes CNC routers reliable not just for simple tasks, but also for complex and intricate designs.

Advantages Over Traditional Cutting Methods

Compared to other foam cutting techniques, the CNC router offers unparalleled accuracy, reliability, and efficiency. Many foam cutting methods utilize traditional tools, which rely on the operator’s input. This can severely impact consistency and lead to higher material waste. The automation that comes with CNC routers completely eliminates these problems, guaranteeing every operation is identical to the previous and every cut comes out as envisioned.

Using CNC routers also streamlines production. Research has shown that the routers improve precision during sanding and foam shaping tasks, increasing accuracy by 30 percent compared to other manual methods. Not only does this eliminate unnecessary steps in custom orders, but it saves companies time.

Most importantly, CNC routers integrate with design-change automation software, which can enhance flexibility and eliminate downtime. Combined with their ability to process elaborate orders and their unparalleled speed, this foam-cutting method results in drastically reduced turnaround times. Studies show that when integrated with these other methods, CNC routers can cut up to five times faster than traditional techniques.

CNC routers today offer modern safety measures, unlike old school tools which posed injury risks during manual operations. Because of foam cutting’s modern technological industrial evolution, a greater degree of safety and automation has been integrated. As a result, foam cutting CNC routers have become one of the modern foam cutting tools in terms of efficiency and automation.

Increased Productivity and Accuracy

Even by other standards, I think projects which implement CNC routers have increased productivity and accuracy. They facilitate detailed designs’ execution while greatly lowering error chances, thus, time, materials and finances. Efficient operation of precise cutter driven by computer guarantees ultimate accuracy and quality achieved results, proving that these devices are critical in obtaining professional results.

What are the Ideal Bits and Tools for Foam Cutting?

Foam cutting requires the use of specific tools like CNC router bits made for soft materials. Single-flute and O-flute bits are great options because they reduce heat buildup and cut cleanly. For thicker foam, compression bits can be used to reduce surface and edge fraying. Moreover, hot wire cutters are preferred for clean and precise cuts on all kinds of foam. Regardless of the tool selected, it has to match the density of the foam and the requirements of the project, but all tools need to be designed to make sharp and clean cuts to obtain the best results.

Examining Solid Carbide and Other Elements

When adapting with foam and lightweight materials, solid carbide tools are best due to their efficiency and sturdiness. Carbide as a material is tough and has a long lifespan, able to keep a sharp cutting edge for a long time thus reducing the need for replacement. Compared to high-speed steel (HSS) tools, carbide tools can exceed their lifespan by more than 10 times, which makes them very economical for repetitive and large-scale projects.

Carbide tools are, undoubtedly, the best in high-speed vertical CNC milling and routing operations. As a case in point, compression solid carbide bits are designed to cut with the material’s clean edges being compressed simultaneously. According to manufacturers’ data, 2 + 2 flute compression bits (2 up-cuts and 2 down-cuts) are best when cutting foam billets between 10mm and 50mm thick, minimizing fraying and maintaining consistent finishing quality.

While carbide is still the preferred material, other like diamond grit tools are becoming more prominent due to their long-lasting edges and ability to precisely work on dense, abrasive foams. Diamond plated cutting tools have excelled in high precision fields such as aerospace and medical-grade foam component manufacturing. For nichrome wire hot wire cutting, nichrome remains unrivaled due to its heat resistance and ability to hold temperature, providing smooth, accurate cuts.

The perfect option rely on the specific project, foam density, and finishing requirements. Innovation is continuously developing solutions to increase usability freedom, efficiency ease, and precision possibilities for professionals and enthusiasts alike.

Choosing Between Hot Knife and Laser Cutting

Hot knife and laser cutting differ in precision, speed, material compatibility, cost, and application suitability.

| Key Point | Hot Knife | Laser Cutting |

|---|---|---|

| Precision | Moderate | High |

| Speed | Moderate | Fast |

| Material Range | Limited | Wide |

| Operating Cost | Low | High |

| Setup Cost | Low | High |

| Maintenance | Simple | Complex |

| Applications | Basic Cuts | Intricate |

| Edge Finish | Smooth | Polished |

| Safety | Relatively Safe | Requires Care |

| Environmental | Minimal Impact | Fumes Emitter |

Finding the Right 3-Flute and End Mill Options

Each of the end mills and 3 flute options has a specific purpose which distinguishes them from each other. A3 flute end mill is often used due to its chip clearing and cutting characteristics. It is a good fit for softer materials like aluminum which gets efficiently surfaced with smooth cuts. In general, end mills come in different varieties which are optimized for a wide range of milling operations.

Other different considerations include type of material being machined, quality of the finish, and machining speed. For instance, harder materials are drilled with higher flute counts whereas softer metals have fewer flutes which increases chip removal. A well defined and scoped project will help ensure the precision, efficiency, and optimal outcomes with ease.

How to Optimize Speed and Feed Rate for Foam Cutting?

For cutting foam, higher spindle speeds with a high feed rate are best for preventing tears and rough edges. Make sure the feed rate and foam’s density are matched with the cutting tool needed to ensure clear, precise cuts. Always begin with a test piece first to hone in on the ideal settings balance.

Cutting Foams at the Right Speed

While determining the right RPM (Revolutions Per Minute) of foam cutting, it is crucial to think of the foam, tool geometry, and the end results needed. Softer foams like polyurethane tend to need higher RPMs, about 18,000 to 24,000. This will help avoid tearing and achieve a smooth finish. Denser foams such as polystyrene perform better in the range of 12,000 to 18,000 RPM as it maintains a good balance of precision and material removal rates.

Mind the cutting tool’s material and geometry design too. Well designed tools such as carbide or diamond coated ones can withstand higher RPMs due to their heat resistant nature. Further refinements on the RPMs can be achieved and controlled using variable frequency drives (VFDs), where adjustments can be made inline for better results.

It is now evident that the cutting speed should be aligned with the foam’s density. Like in the study conducted in 2023, increasing the RPM by 10% reduces edge fray on softer foams by 15%. This shows how much change even the most minor of adjustments can make when cutting foam. Remember to always follow the manufacturer’s recommendations for materials, tool selection, and RPMs to achieve best results while ensuring safety, tool lifespan, and long term utilization.

Adjusting Feed Rate Based on Foam Density

Achieving clean cuts, shaping hardened foams with tools, and extending tool life is reliant upon using an optimal feed rate when cutting soft foam or foam of varying density. New studies show that slow feed rates are required for thick foam materials to prevent overheating and enable smoother finishing along the edges. A case in point is high-density polyurethane foam. In a 2023 study that focused on material analysis, it was concluded that surface irregularities on high-density poly-urethane foam increased by 18% due to a 20% reduction in feed rate.

On the opposite end, lower-density foams, such as expanded polystyrene, are more responsive to moderately increased feed rates; a 10% increase led to a decrease in processing time while maintaining accuracy. It is also advisable to track feed rate changes with CNC machine presets that allow for calculated changes based on material and blade specs. Always use real-time monitoring where available to make adjustments for precision in every variable.

Methods To Reduce Scrap and Improve Efficiency

One approach to reduce scrap is more accurate precision sensors. The most recent statistics indicate that sensors on CNC machines can eradicate material waste by detecting inaccuracy by 20% in real-time. In addition to this, design flaws can also be detected through simulation software before actual production, which studies believe can reduce scrap rates by 15%.

Lean Manufacturing principles also offer a different approach. These study suggest Just-in-time inventory control and process standardization greatly improve efficiency. Adopting Lean techniques has led some companies to report reduction in overall production waste of 30% while simultaneously improving throughput by 25%.

Moreover, implementing automated inspection systems offers uniform quality assurance. The most recent… Advanced machine learning technologies enable inspection tools to identify defects with more than a ninety-five percent accuracy rate. This automation greatly reduces the probability for rework or rejection of parts. Industries that leverage both approaches stand to gain optimal efficiency and reduced scrap rates.

Reference sources

- PERANCANGAN ALAT PENCEKAM UNTUK PEMESINAN POLYURETHANE FOAM PADA PROSES FACE MILL CUTTING MESIN CNC ROUTER 3 AXIS DENGAN METODE VDI 2221 (2024) (Utomo et al., 2024)

- Key Findings:

- Due to the highly brittle structure of polyurethane (PU) foam, a specialized clamping mechanism is required to avoid damaging the workpiece and withstand the cutting forces during milling and machining.

- Using a polymer as an alternative for creating clamping tools with characteristics similar to PU foam offers a promising solution.

- The VDI 2221 method, a structured approach to the design and coordination of evolving design techniques, is employed in this study.

- A comparative analysis of two design models produced via 3D printing reveals that Design 5 exhibits superior strength under increased stress and is more effective in gripping the workpiece.

- Methodology:

- Utilized the VDI 2221 method for the design and development of a specialized clamping mechanism for PU foam machining on a CNC router.

- Compared the performance of two 3D printed clamping tool designs through comparative analysis.

- Key Findings:

- Design of Low Cost Mini CNC Laser Engraver (2023) (Barakat et al., 2023, pp. 81–84)

- Key Findings:

- A low-cost Mini CNC Engraver is proposed to decrease complexity, expense, and labor for engraving 2D grayscale images or drawings using a high-watt laser module on various surfaces.

- Experimental testing demonstrates that the system can serve as a cutting and engraving tool for miniature samples.

- Methodology:

- Designed and implemented a two-dimensional CNC router that can engrave 2D grayscale images or drawings using a high-watt laser module.

- Conducted experimental testing to evaluate the performance of the developed Mini CNC Engraver.

- Key Findings:

- Curbing sediment: The effects of added surface roughness in the curb and gutter as a novel pretreatment for green infrastructure stormwater control measures (2023) (Grimm et al., 2023, p. 118370)

- Key Findings:

- Alterations were made to the standard curb and gutter, which is ubiquitous within urban environments, to increase the roughness of these surfaces using a CNC router.

- Patterns which included added roughness in both the curb and gutter reduced total suspended solids (TSS) concentrations by up to 95% and reduced median particle size in runoff.

- Continued TSS removal was observed during repeated testing designed to simulate up to seven runoff events, indicating the potential for sustained sediment accumulation before the need for maintenance.

- Methodology:

- Constructed mock road sections made of expanded polystyrene (EPS) foam using a CNC router to add various patterns of surface roughness to the curb and/or gutter.

- Evaluated the sediment removal performance and particle capture of the roughened curb and gutter sections through laboratory simulations of stormwater runoff.

- Key Findings:

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CNC Router for Foam?

A: A CNC Router for foam is a type of computer-aided machine that slices foam into shapes and designs that need precise cuts. In manufacturing, it is widely used for mold making, insulation, and foam for packaging purposes.

Q: How does CNC routing for Foam differ from other materials?

A: In CNC routing for foam, softer materials such as EVA, polyethylene, and urethane are cut. Unlike other materials, foam is softer and needs to be worked on with a specific set of tools and low feed rate in order to avoid tearing the edges.

Q: Can a CNC router be used for 3D foam cutting?

A: Sure, with the use of sophisticated programs to draft detailed three-dimensional figures, CNC routers can support three-dimensional foam cutting. It is often used to design custom molds and prototypes.

Q: What are the benefits of using a camaster CNC for foam cutting?

A: The benefits of using Camaster CNC machines includes accuracy, consistency, speed and efficiency with foam cutting. Also, they have special features like adjustable spindle speeds and foam tooling that suits foam cutting.

Q: Can other materials like plastic or MDF be processed with a foam cutting CNC?

A: A foam cutting CNC is capable of processing plastic and MDF. Though, it needs different tooling and machine settings. It’s important to set the machine correctly for every material to achieve the desired results.

Q: Which types of foam can be cut with a CNC router?

A: Polyurethane, polyethylene and EVA foams are some of the foams that can be cut with a CNC router. Every type of foam has its properties which might need some specific cutting methods and tools.

Q: How to purchase the correct CNC router for foam projects?

A: While purchasing a CNC router intended for foam projects, make sure to verify the dimensions of the work area, the spindle power, if it works with 2D and 3D drawings and if it can work with other types of foam. Industrial CNC machines by brands Camaster meet those requirements.