Whether for leisure or work, carbon fiber’s strength-to-weight ratio offers unmatched versatility and can change the game. However, working with carbon fiber isn’t easy—machining it requires the proper tools, absolute precision, and an in-depth knowledge of the cut process. Enter CNC routers. In this post, we will explain the unique difficulties this high-performance composite poses, how to choose appropriate router settings, proper bits, and successful techniques. While even the most experienced machinists will learn something new, beginners will gain the confidence and assurance needed to elevate all their future endeavors. For complete mastery of carbon fiber machining, keep reading.

What is a CNC Router for Carbon Fiber?

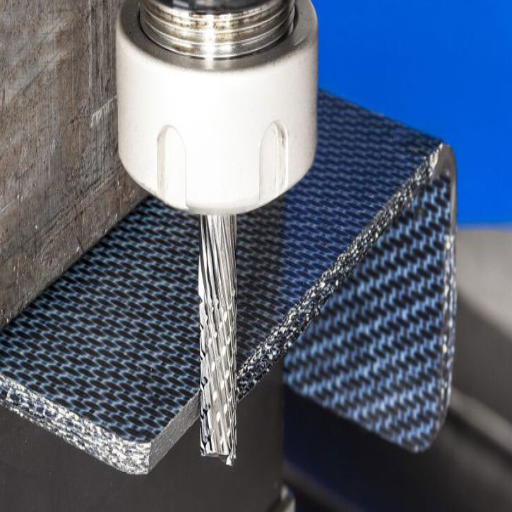

A CNC router for carbon fiber is a sturdy, computer-aided engraving machine specifically tailored to design carbon fiber details precisely. It functions by rotating at high speeds while cutting or milling the fiber to shape it according to the blueprints given to it.

Because carbon fiber has rough qualities, CNC routers for this material come with specialized bits, vacuum systems for dust control, and precision cutting settings for Surface finish. These machines ensure clean and efficient cuts while maintaining minimal fraying and damage to the carbon fiber.

How CNC Routers Work with Carbon Fiber

When working with carbon fiber, CNC routers adhere to an exacting schedule. These machines are programmed to operate with Computer-Aided Design (CAD) files, manipulating high-speed cutting tools along specific paths. Because of the material’s abrasiveness, the interaction of cutting tools with carbon fiber must follow precise parameters. Standard tools, for example, can be rendered useless all too quickly. Therefore, carbon fiber CNC routers are fitted with diamond-coated or carbide-tipped tools, which aid in enduring the tough composition.

While operating on carbon fiber, parameters such as speed, feed rate, and spindle RPM have to be balanced to prevent overheating while retaining edge quality. Extensive testing has established ideal parameters, with spindle speeds often ranging between 15,000 and 25,000 RPM and feed rates reliant on the thickness of the material. Adaptive technology is featured in advanced routers, allowing such parameters to be modified in real time. This drastically minimizes errors and guarantees consistent results.

Machining carbon fiber requires specialized dust collection systems – the process produces tiny, sharp particles that could be detrimental if ingested, not to mention hazardous to equipment. The modern-day CNC router is equipped with some of the best tools for shielding, from high-efficiency vacuum systems to downdraft tables that capture debris with incredible precision. They put the operator’s safety and machine longevity at the same time.

As per new sector information, CNC routers help fuel the demand in aerospace, automotive, and sporting goods markets as the demand for carbon fiber is rising. For instance, reports indicate that CNC machining can achieve tolerances as tight as ±0.005 inches (0.127 mm), which meets the CAD/CAM system engineering standards. With new technologies in CNC, in particular AI-driven programming, the systems are about to change the processes once more for carbon fiber for the better.

Benefits of Using CNC for Carbon Fiber Machining

- Precise and Accurate Measurements

CNC machinery offers unrivaled precision, with Accuracy as precise as ±0.005 inches (0.127 mm). This precision ensures that even complex, intricate carbon fiber components pass technically demanding standards, boosting industry standards and providing refined products and enhanced performance.

- Enhanced Efficiency and Speed

CNC machining processes carbon fiber components more mechanized, which saves time compared to other methods. Automated processes boost manual and error efficiency, meaning increased productivity, where precision is the goal during mass production manufacturing.

- Reliability and Consistency

Performance with CNC technologies allows manufacturers to maintain identical quality and precision over several production runs. This is fundamental for industries such as aerospace and automotive, where variations in component reliability are unacceptable.

- Versatility for Complex Designs

CNC machines are capable of achieving high standards for complex geometry and detailed patterns because carbon fiber requires accuracy from the lighter materials used in components for aircraft and automotive when the high speed demands precision the unique needs of different designs and aeronautical parts.

- Material Optimization and Carbon Footprint

CNC machining optimizes material by precision cutting carbon fiber, which guarantees no excess leftover pieces. This precision also equips companies to reduce waste costs while enriching their sustainability objectives.

How to Choose the Right CNC Router for Carbon Fiber Sheets?

For machining carbon fiber sheets, a CNC router must be picked with the following considerations in mind:

- Cutting Accuracy and Stability

The precision grade of CNC router carbon fiber is best with units with very accurate cutting track capabilities, as this directly determines cut cleanliness. Given the rigidity of carbon fiber, workstations must be very well built to absorb vibrations when cutting at high speeds.

- Compatible Cutters

Make sure the CNC router can accept diamond-coated or carbide cut tools. These tools cut best when working with carbon fiber’s abrasive traits.

- Dust Collection System

Make sure that the router allows for efficient dust collection in the carbon fiber dust created when routing. If not handled correctly, this can be dangerous for people and machines alike.

- Motor Power and Spindle Speed

Avoid routers for carbon fiber whose spindle speed is not adjustable; the same goes for power – the stronger, the better. The carbon fiber should withstand the router’s heat without burning or tearing the material.

- Software Support and Work Ergonomics

Ergonomically designed user interfaces will streamline numerous processes by automating many tasks for which the programmer would need to pre-emptively design conditions, so choose a machine with active designer support and modern software.

Focusing on these points will make selecting a suitable CNC router for machinability, safety, and efficiency on carbon fiber sheets achievable.

Key Features to Look for in a CNC Machine

Optimal projects require examining certain features when selecting a CNC machine, as these elements guarantee optimal performance. To assist you in making a decision, we have listed the five main features needed:

- Cutting Accuracy and Precision

CNC machines should offer precise tolerances and repeatability within ±0.001 inches, but most importantly, superb accuracy. This is needed for every detailed and intricate design. Such machines will have linear guides and robust frames.

- Material Flexibility

A CNC machine that works with wood, metals, plastics, and carbon fiber composites is best suited. However, ensure that it has the versatility to support other materials, too. It must have adjustable cutting parameters and set blades to accommodate various material hardness and thicknesses.

- Overall Sturdiness

Spindle motors with adjustable speed control and wattages of 1.5 kW or more are ideal since they can be outfitted for a variety of tasks and handled flexibly. This is critical when machining various materials, as it avoids damaging the workpiece.

- Vibration Dampening Accuracy

When the frame is made from either cast iron or steel, it results in a durable and well-constructed CNC machine. This reliability will limit the vibrations encountered during machining, thus providing unrivaled stability and error-free results.

- Detailed Software Compatibility

A CNC machine must accept sophisticated software such as CAD/CAM for design and programming purposes. User-friendly interfaces and support of accepted formats like G-code enhance automation, process control, and efficiency in the machining workflow.

Top CNC Router Models for Cutting Carbon Fiber

- Shapeoko 4 CNC Router

The Shapeoko 4 is a multifunctional CNC router built to last and operate precisely. It can cut carbon fiber sheets with high spindle power. It works with Carbide Create, G-Code, and many other popular software, making it user-friendly for novices and experts alike. The machine has a cutting area of 33″ x 33″, enabling it to perform large projects. Its sturdy aluminum frame further reduces vibration, which, together with the cutting area, helps produce clean cuts with minimal distraction.

- X-Carve Pro CNC Router

Its industrial-grade performance makes X-Carve Pro one of the best CNC routers to cut carbon fiber. It also manages this while drawing 2.0 kW power from the high-speed spindle, so tough materials are no issue. The router has bluetooth and connections for built-in dust collection, wasteboard clamps, and even carbon fiber using tools to ensure operations are clean and safe. The X-Carve Pro offers an intuitive interface, easy design engineering software, and a wide range of design options, which make frame adjusting effortless. 4′ x 4′ cutting capacity best suits the router for complex tasks.

- BobsCNC Evolution 4

The Bob’s CNC Evolution 4 has received compliments due to its solid construction and reasonable pricing. It has an all-wood frame that helps cut performance for small and medium-sized projects. It can cut carbon fiber due to the metal parts incorporated for additional stability. Weighing in at 24″ x 24″, the carbon fiber sheets are handled effortlessly with their 600W spindle motor. No assembly is needed for this purchase; it can be fully adapted and changed due to its open-source design, a special feature that cheers professionals and hobbyists up.

- Omni CNC Router 1212

The most significant flaw in the Omni CNC Router 1212 is its cost. This has benefits as it has specialized features for cutting carbon fiber, which can easily support heavy-duty work. Equipped with a 3.0 kW air-cooled spindle, the cutting performance is maximized. Not to mention the vacuum table, which is used with this part, will also hold the material securely while machining. Not eliminated, sophisticated DSP control and CAD CAM compatibility are world-topping features for this machine, alongside 4’ x 8’ cut space, fit for industrial-scale projects. Well known for its speed, precision, and dependability.

- CNC Shark HD520

With high-performance capabilities, the CNC Shark HD520 is perfect for professional-level cutting. It has a powerful 2.24HP water-cooled spindle and a meticulously crafted gantry system, which makes it incredible at cutting carbon fiber without fraying or roughing the edges. The aluminum frame also helps to reduce deflection during intensive machining tasks. Along with VCarve Desktop and VCarve Pro, the Shark HD520 is an excellent option for shops with intricate designs and prototype machining due to its 25” x 50” cutting area.

As with all other CNC routers, motor power, cutting area, build quality, and software compatibility are key when selecting a CNC router for cutting carbon fiber. These machines stand out as some of the most dependable and efficient in the industry, whether for personal or commercial use.

What are the Best Practices for Cutting Carbon Fiber?

- Use the Correct Equipment—When working with carbon fiber, use machines designed for it, like diamond or carbide saws, to cut the material without damaging it so that it remains clean and precise.

- Make Sure the Material is Properly Secured—To avoid frayed or misplaced cuts, make sure that the carbon fiber is properly clamped so that it does not move during the cut.

- Complete Tasks In An Area That is Well Ventilated—Always remember that cutting carbon fiber produces fine dust that can be hazardous if inhaled, so be sure to ventilate the area. Additionally, protective wear such as dust masks or respirators should be worn.

- Maintain Proper Cutting Speeds—Always check that the cutting speed is moderate to prevent overheating and harm to the material and the cutting tool.

- Check Edges After the Cut is Complete—Check for flaws such as cracks or fraying. If there are any, and the piece needs to enhance its durability and aesthetic quality, then sand or seal the edges.

These practices will help maintain the workspace safer, achieving precise cuts and conserving the carbon fiber’s structural precision.

Preparing Your Carbon Fiber Sheet for Machining

Proper prep work is instrumental in ensuring accuracy and preserving the quality of your carbon fiber sheet during machining. The following steps can help you get started with the most relevant and recent information:

- Thoroughly Clean and Inspect the Sheet

Prior to machining, the composite sheet needs to be scrubbed down free of dust and any oils that can disrupt machining. Lint-free rags should be used, along with appropriate solvents like isopropyl alcohol that won’t contaminate the surface. Also, check the sheet for any craters, surface blemishes, fractures, and other weak areas that will disrupt the whole machining process and its outcomes.

- Secure The Sheet Well

Due to their light weight and stiffness, carbon fiber sheets tend to vibrate during machining. To combat this, the material should be locked down tightly with clamps, vacuum tables, or double-sided adhesive tape. This will mitigate movement during cuts and enable greater accuracy while preventing cracks or uneven edges.

- Find the Appropriate Cutting Speed and Tooling

Found that the best techniques for machining carbon fiber are with diamond-coated tools or carbide tools due to their wear and heat resistance. Higher helix angle cutting tools (approximately 30-50 degrees) provide better chip removal and smoother finishes. Also, moderate feed rates and spindle speeds should be observed because overheating carbon fiber damages the resin matrix. For most materials, the spindle speed can be set between 10,000 and 20,000 RPM, and material thickness will determine the RPM value within the range.

- Drill Holes Preemptively Where Necessary

Low-speed pre-drilling can achieve clean cuts without fraying the material while making holes or mounting points. Keeping the material in place prevents blowout and is achieved with the use of sacrificial boards.

- Select the Right PPE

Machining processes create carbon fiber dust, which is dangerous when breathed in. Therefore, proper PPE, such as an N95 respirator or above, protective eyewear, and gloves, must be worn. Effective dust extraction systems can maintain workplace cleanliness and safety.

Considering newer methods and tools and fabricating the carbon fiber sheet properly ensures optimal results, minimal error, and safety in the surrounding environment.

Optimal Settings for CNC Routing Carbon Fiber

Diamond-coated tools should be used to achieve the best results while CNC routing carbon fiber. Additionally, slower speeds, shallow cuts, and better dust control will improve outcomes.

| Parameter | Optimal Setting |

|---|---|

|

Tool Type |

Diamond-coated |

|

Speed |

Slow |

|

Feed Rate |

Low |

|

Depth of Cut |

Shallow |

|

Dust Control |

HEPA filter |

|

Workholding |

Stable clamps |

|

Cooling |

Optional water bath |

|

Tool Wear |

Monitor regularly |

Tools and Materials Needed for CNC Cutting

Accomplishing the CNC cutting will require the following tools and materials, especially for difficult materials such as carbon fiber:

- CNC Router—A sturdy CNC with a good reputation and recovery rate must be consistent in accuracy, give consistent results, and withstand the material’s rigidity.

- Diamond-Coated or Carbide Tools—Tools made of either diamond or carbide are ideal because they can withstand abrasive materials such as carbon fiber.

- HEPA Vacuum—A vacuum with a HEPA filter is essential for better control of dust and harmful particulates in the air.

- Stable Clamps or Fixtures – To capture the work piece and ensure minimal vibrations during cutting.

- Protective wear—To protect the operator against the fine dust produced, a respirator, gloves, and protective eyewear must be worn.

- Lubrication or Cooling System—A lubricant, such as a water mist or bath, can decrease heat and prolong the tool’s life.

- Carbon Fiber Sheets or Slabs – The required raw material is cleaned and prepared beforehand.

- Monitoring Devices—Adjustable tool wear, spindle speed, and other parameters can be monitored to ensure optimal operations.

- Software for CNC Programming – Sophisticated software makes creating toolpaths and CNC machine movement control easy.

Like all machining operations, CNC cutting requires careful planning. Using high-quality materials and tools enables precision, safety, and efficiency in CNC cutting, aligning with the industry’s best practices and modern innovations in machine work.

How to Handle Carbon Fiber Dust and Safety Precautions?

To manage and mitigate the risks of carbon fiber dust collection efficiently, observe these primary guidelines:

- Personal Protective Equipment (PPE): At a minimum, a NIOSH-approved respirator, safety goggles, and gloves may cover exposure to the respiratory system, eyes, and skin.

- Maintain Adequate Airflow: Work from a location where fresh air is freely available, or use local exhaust ventilation systems designed to minimize airborne dust concentrations.

- Dust Control Systems: For dust and fine particle vacuuming, use specialized vacuum systems or dust collectors built to capture particulate matter.

- To Avoid Skin Exposure: Wear long-sleeved apparel to avoid being exposed to carbon fiber dust, which may lead to skin irritation (itching).

- Maintain Clean Work Areas: Clean using wet techniques or a vacuum, as opposed to sweeping, which generates clouds of dust.

- Incorrectly labeled:[Waste Removal] Remove Waste. Incorrectly Labeled: Do Not Place Waste Wrongly: Leave Wrong Waste in Wrong Place: Clean-Up Point

Seal dust and collection bags, then place them into waste containers designated for sealed waste dust, and follow the local waste disposal guidelines.

Following these guidelines will help ensure acceptable health standards and safe work conditions.

Health Risks of Carbon Fiber Dust

The health hazards associated with carbon fiber dust include the development of chronic respiratory illnesses, dermatitis, eye inflammation, lung diseases, and other latent conditions such as mesothelioma.

| Risk | Description |

|---|---|

|

Respiratory |

Breathing issues, lung irritation |

|

Skin |

Irritation, redness |

|

Eyes |

Redness, itching |

|

Lung Disease |

Pneumoconiosis, mesothelioma |

|

Allergic |

Sneezing, watery eyes |

|

Combustion |

Fire hazard |

|

Chronic |

Long-term lung scarring |

Effective Dust Collection Methods

Remaining within the permissible occupational exposure limits for carbon fiber dust entails efficient dust collection techniques. These techniques include using specialized industrial HEPA filter vacuums to effectively remove airborne carbon and fiberglass dust. Additionally, central dust collection systems enhance the performance of workstation enclosures by continuously removing dust from the workstations.

Wet or submerged dust extraction units also effectively clean air laden with solid dust since they rely on trapping dust in a liquid medium. They are most effective for highly dusty environments due to their ability to significantly reduce the risk of trigger inhalation or ignition. Furthermore, enclosing work areas coupled with downdraft source local exhaust ventilation (LEdV) ensures that dust suspension is limited to designated areas and removed at the source.

Together with routine equipment servicing and following set safety measures, these approaches minimize performance exposure to dangerous carbon fiber dust. Companies can enhance workplace health and compliance standards by adopting the latest technological advances in dust collection.

Reference Sources

1. Tensile Strength of Carbon Fiber/Epoxy Composite Manufactured by the Bladder Compression Molding Method at Variable Pressure Levels(Ismadi & Nugroho, 2020)

- Publication Date: 2020-01-23 (Within the last 5 years)

- Methodology: Woven carbon fabric and epoxy matrix were used to create a composite material using the bladder compression molding method at varying pressure levels (1, 2, 3, 4, 5, 6, 7, and 8 bar). Test specimens were cut from the resulting composite using a CNC router. Tensile tests were then performed on these specimens.

- Key Findings: The research found that the ultimate tensile strength was 604 MPa, with the optimal pressure for the bladder compression molding being 7 kPa. The study concluded that increasing bladder pressure improved composite quality to the optimal pressure point.

2. Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is the best CNC router bit for machining carbon fiber?

A: The best CNC router bits for machining carbon fiber are typically made from polycrystalline diamond (PCD) or carbide. These materials provide the cutting edge necessary for precisely cutting through tough carbon fiber parts without dulling quickly.

Q: Can I use a desktop CNC to mill carbon fiber?

A: Yes, you can use a desktop CNC to mill carbon fiber, but ensure it has sufficient power and rigidity to handle the material. Using the appropriate CNC carbon fiber bits designed for high-performance cutting is also important.

Q: What should I consider when cutting carbon fiber on a machine?

A: When cutting carbon fiber on a machine, consider the feed rate, spindle speed, and the type of router bit used. Proper dust extraction is also crucial to manage carbon dust and maintain a clean workspace.

Q: Is using a laser cutting or CNC milling machine for carbon fiber is better?

A: It depends on the application. CNC milling is ideal for creating complex 3D shapes and parts, while laser cutting is better for precise cuts on flat carbon sheets. Each method has its advantages based on the desired finish and detail.

Q: How do I prevent carbon dust buildup when milling carbon fiber?

A: To prevent carbon dust buildup when milling carbon fiber, use a high-quality dust extraction system during machining. To maintain optimal performance, regularly clean the work area and the CNC machine.

Q: What is CFRP, and how is it related to CNC carbon machining?

A: CFRP stands for Carbon Fiber Reinforced Polymer, a lightweight and strong composite material. CNC carbon machining is commonly used to create parts from CFRP, allowing for precise and intricate designs suitable for various applications.

Q: Can I cut fiberglass using the same CNC router bits as carbon fiber?

A: While some CNC router bits can cut both fiberglass and carbon fiber, it is advisable to use separate bits. The different properties of these materials may require specific tooling to achieve the best results without damaging the bits.

Q: How thick of a carbon sheet can a CNC router handle?

A: The thickness of the carbon sheet that a CNC router can handle depends on the machine’s capabilities, including its power and rigidity. Generally, most CNC routers can handle sheets up to 1 inch thick, but check your machine’s specifications for optimal performance.

Q: What type of epoxy resin is best for use with CNC carbon parts?

A: For CNC carbon parts, a high-performance epoxy resin with excellent bonding strength and durability is recommended. Look for epoxy resins specifically formulated for composite applications to ensure the best results.