Ready to embrace the unlimited possibilities that precision manufacturing has to offer? It doesn’t matter if you are a hobbyist, a small business owner, or someone stumbling upon CNC routing for the first time; finding the right CNC machine can feel overwhelming. With many options in the market, how do you know which one perfectly aligns with your needs? Worry not, this guide aims to ease your dilemmas.

This article will cover all the essential details regarding selecting the best CNC router for beginners. Yes, we will cover everything from the critical features of different models to their advantages and disadvantages. By the end, you can confidently make a decision that aligns with your needs, budget, and skill set. Get ready to immerse yourself in the captivating world of CNC technology and bring your beautiful ideas to life!

What is a CNC Router Machine and How Does It Work?

A CNC router is a cutting tool that carves, engraves, and shapes a variety of materials like wood, metal, plastic, and foam. Its inner workings entail following instructions via CAD (Computer-Aided Design) software that gets directly converted to CAM (Computer-Aided Manufacturing) code. The machine then guides the cutting tool to yield desired shapes and intricate designs with unmatched precision. Accuracy and efficiency are why this technology has become prominent in woodworking, manufacturing, and prototyping industries.

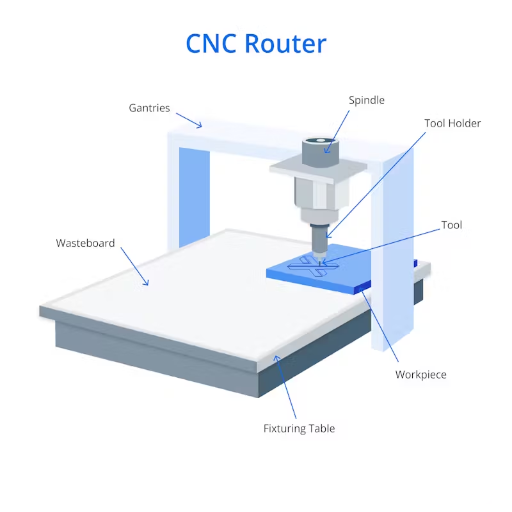

Components of a CNC Router

A CNC (Computer Numerical Control) router consists of many essential parts that come together to execute efficient and accurate machining processes. Below is a breakdown of its key components and their respective details:

- Frame and Gantry

The frame is the CNC router’s supporting skeleton to maintain operational stability. Frames are made from aluminum or steel due to their rigid nature and minimal vibrational damping. The gantry is the upper bridge with the cutting tool attached, and it moves along the frame in the X-Y axes.

Spindle: A modern example is the use of aluminum frames with added steel reinforcements to mitigate deflection while increasing rigidity. Industrial-grade routers, for example, can support over 1,500 lbs of weight.

The spindle is a critical component of the cutting process. It propels the cutting tool at high speeds, exceeding 12k RPM, enabling precise material cutting. For certain materials, the maximum RPM rate is 24,000.

– Latest Innovation: Introducing high-frequency spindles has been revolutionary, especially with liquid cooling systems for optimized performance and lower wear and tear.

- Cutting Tool – Router Bit

Router bits are tools that are used in rotary woodworking machines. They specialize in specific intended engraving, carving, or drilling works. They are manufactured from high-speed steel and/or carbide.”

Data Insight: In a deeper sense, advanced carbide bits can endure rough materials like aluminum and composites greatly, so much so that they outlast standard steel bits by 3 to 5 times.

- Drive System

Like other CNC machines, CNC routers have a drive system comprising stepper or servo motors that move the machine in X, Y, and Z coordinates. Stepper motors are fairly economical and precise, while servo motors are faster and more precise, thus preferred in industrial settings.

Performance Benchmark: One major advantage servo motors have over stepper motors is that they can achieve a position responsiveness of up to 0.001 inches, which makes them desirable for many demanding applications.

- Controller

The controller, or the brain of the system, receives G-code instructions and moves relative to the machine without defaulting to the integrated logs of movements. It further controls the synchrony of other parts integrated to it for ever-precession in repeatable machining.

– Feature Highlight: Controlers now feature touch screen panels improving ease of use and have Wi-Fi for internet connection.

- Vacuum Hold-Down System

This apparatus keeps the workpiece fixed to the router bed to avoid movement during machining. Vacuum systems work better for large flat materials because they do not require clamps for certain configurations.

Efficiency Rate: Modern vacuum pumps can efficiently maintain a pressure difference of up to -85kPa, guaranteeing a good grip.

Linear guides and bearings ensure proper movement of the gantry and cutting tool. They also ensure low friction, which minimizes damage and increases the machine’s life.

Latest Standards: Nowadays, rails produced under the ISO 9001 mark are widely used in upper-class CNC routers to increase their dependability.

- Dust Collection System

CNC routers generate a large quantity of debris when cutting wood and composites. Moreover, a dust collection system stops pieces from drifting away, keeping the workspace tidy while protecting delicate parts.

– Environmental Compliance: Numerous systems now incorporate HEPA filters capable of trapping 99.97% of dust particles bigger than 0.3 microns.

Integrating these components with other technologies enhances the functionality and precision of CNC routers, making them vital instruments in the aerospace, automotive, and furniture industries.

How CNC Routing Differs from Traditional Woodworking

The best cnc routers for beginners differ from traditional woodworking tools in terms of precision, speed, and consistency due to the automation of computers performing the work.

| Aspect | CNC Routing | Traditional Woodworking | Key Note |

|---|---|---|---|

|

Precision |

High |

Moderate |

Accuracy |

|

Speed |

Fast |

Slower |

Efficiency |

|

Consistency |

Uniform |

Variable |

Repetition |

|

Skill Level |

Software knowledge |

Manual expertise |

Learning curve |

|

Designs |

Intricate, complex |

Unique, handcrafted |

Creativity |

|

Cost |

Higher initial |

Lower initial |

Investment |

How to Choose the Right CNC Router Kit for Beginners?

Considering the factors mentioned below will simplify selecting a cnc router kit.

- Look for kits that contain clear instructions and require few assembly steps. This will provide a better learning curve for beginners, as proper instructions simplify learning.

- Select a router with a workspace that aligns with the scope of your projects. Opt for medium-sized kits that accommodate soft materials such as wood and plastic, which beginners can efficiently work with.

- Having a set price in mind makes the search process a lot easier, as you can choose a kit that will maximize the value of your budget. Many starter kits exist that are both cheap and provide the basic operations necessary.

- Make sure the programs associated with the kit are user-friendly and suitable for beginners. The software included should be easy to use or popular for design and operation.

- Ensure that the brand you decide to purchase provides proper customer support alongside tutorials, as an active user community aids in troubleshooting and learning. Having a guided community will fast-track the learning process.

Looking at all these guidelines will make it simple for beginners to select the right kit without excessive hassle while having the best chances for positive outcomes.

Factors to Consider When Choosing a CNC Router

CNC routers are available, but consider the following factors for your unique requirements. Based on current search trends and data insights, here are the most suitable options:

- Material Compliance—Define whether your scope includes wood, metal, acrylic, or foam, since not all CNC routers can work with every material.

- Precision and Accuracy—Look for a machine loaded with rich mechanical components like ball screws and linear rails for unparalleled accuracy and smoother operation. These features greatly enhance the ratio of high-precision and accurate results.

- Working Area—Align the size of the working area with your project dimensions. If your designs are large, acquiring a CNC router with a sizeable cutting bed boosts flexibility and operational efficiency.

- Software Collaboration – Assess whether the router comes with simple software or compatibility with design and control programs, as Software partnership impacts ease of design execution.

- “Maintenance and Durability – Acquiring a CNC router that is low maintenance and is of high durability will automatically guarantee value in the long run. Over time, machines built from durable components tend to be more dependable.”

- “Budget and Purpose – State your budget and purpose for the machine router clearly. Beginners and hobbyists tend to use entry-level machines, while seasoned professionals may need something more industrial-grade.”

If you research well, considering the above factors, your spending and decision can be sophisticated enough to align with your skills, objectives, and technological requirements.

Best CNC Router Kits for Beginners

There are numerous options for the best CNC router kits for beginners, all dependable and widely favored. As of the latest trends and statistics, here are some recommended picks:

- Genmitsu 3018-PROVer

This model is one of the cheapest on the market and also the most accessible, given that it has an easy setup process. It is great for beginners because the parts come preassembled. The PROVer has aluminum construction and advanced GRBL control software, which means it can be used for small projects with great precision.

- SainSmart Genmitsu 3018-PRO

This model is compatible with plastics and allows for projects in acrylic and wood. This value option is the first step in PROVer’s line of generations and was designed for those who want to try CNC machining.

- CNC E3 CNC Router

This impressive kit has a wooden frame and can be used on large materials. The BobsCNC E3 also comes with a Dewalt router and GRBL software, making it the perfect choice for beginners who do not want to spend too much but want powerful features.

- MYSWEETY CNC 3018-PRO-M

The MYSWEETY CNC 3018-PRO-M kit is very cheap. It is ideal for users looking to do simple DIY engraving and cutting routines. The upgraded control software enhances the user experience. The kit is compatible with various materials, such as wood and PCB.

These kits are excellent starting options for beginners because they possess individual features and benefits. It is up to you to determine which one best suits your needs. Aspects such as budget, project necessities, and the extent of technical work desired often play a role.

Comparing CNC Routers vs. CNC Mills

CNC dial routers are tailored for softer materials that require high speed and workspaces with larger dimensions; however, CNC mills are used for harder materials that require high precision and higher torque at smaller workspaces.

| Aspect | CNC Router | CNC Mill | Key Note |

|---|---|---|---|

|

Material |

Soft (wood, plastic) |

Hard (metal, steel) |

Material type |

|

Speed |

High RPM, low torque |

Low RPM, high torque |

Cutting force |

|

Work Area |

Large |

Small |

Workspace size |

|

Precision |

Moderate |

High |

Accuracy |

|

Structure |

Lightweight, gantry |

Rigid, heavy |

Build design |

|

Cost |

Lower |

Higher |

Budget |

What are the Best CNC Machines for Beginners?

If one is a beginner in CNC machines, it is imperative that the first choice is simple, inexpensive, and works on entry-level projects. For that, here are some suggestions:

- BobsCNC Evolution 4

Great for woodworking and hobbies.

Quick and straightforward to assemble and operate.

Low priced with a strong wooden structure.

- Shapeoko 4

Reliable performance and an easy-to-use software interface.

Applicable in small to mid-scale works.

Strong and flexible to work with a variety of materials.

- Inventables X-Carve

Created with beginners in mind.

Comes with easier-to-use software and some prebuilt components.

Great for intricate carving and low-volume production.

- Genmitsu 3018-PRO

High precision engraving and compact in size, easy on the wallet.

Perfect for novices looking to try engraving and light cutting.

Instructions are included for easy setup.

The selected machines have been carefully chosen for their ease of use, quality, and features to make them perfect for the first-time CNC users for an effortless experience.

Top CNC Routers for Hobbyists and Small Businesses

Affordability, accuracy, and simplicity are essential when considering CNC routers for hobbyists and small businesses. Based on current data and trends, here are some of the top suggestions:

- Shapeoko 4 XXL

Renowned for its versatility and large work area.

Suitable for woodworking and working with plastic and soft metals.

Maintains a professional quality while still being affordable.

- BobsCNC Evolution Series

Popular among hobbyists for its sturdy wooden frame and easy assembly.

Notable for its accuracy and excellent intricate design capabilities.

Versatile and ideal for small-scale production.

- Inventables X-Carve

Easy to use, accompanied by a wealth of online guides.

Excellent for adding intricate artistic designs or building prototypes.

Comes with software for easy project organizing.

- CNC Piranha FX

Designed for small workspaces, eyes are on compact size without sacrificing power.

3D carving featured alongside multi-material compatibilities.

Highly recommended for space-restricted small business owners.

- SainSmart Genmitsu 4030 PROVer

An upgrade from the beginner Genmitsu 3018 model, delivering improved precision.

Highly affordable and dependable, ideal for hobbyists wanting to level up their tactics.

Well known for engraving wood, plastic, acrylics, and soft metals.

Every CNC router in this selection offers value, functionality, and performance for smaller projects. They meet the expectations of DIY enthusiasts and entrepreneurs by providing efficient outcomes at affordable prices.

Features to Look for in a Beginner CNC Machine

To ensure everything goes as smoothly as possible when setting up your first CNC machine, be sure to pay attention to the following five features:

- Build Volume

Ensure your CNC machine has enough build volume for the work you wish to do. For small-scale designs, a work area of 300mm x 180mm x 45mm, or larger, is ideal.

- Ease of Use

If you’re new to the CNC world, having a well-structured CNC interface that can work seamlessly with graphical programs such as GRBL will be essential. As with all electronics, the simpler the controls, the easier learning is.

- Frame and Build Quality

For precise and accurate results, the CNC machine has to be built of materials that enhance durability and reduce vibrations during operation. Models made of thick aluminum or steel make good choices.

- Spindle Power

Select a machine with a spindle power appropriate for your chosen materials. A spindle motor with 300W to 500W should be enough for those starting and wishing to work with wood, plastics, or soft metals.

- Affordability and Support

There’s no need to break the bank when you first start out, and certainly no need to spend more than $400$. Make sure the manufacturer guarantees reliable customer support and has an active online forum for troubleshooting and guidance.

Considering these features can help you find a reliable CNC machine that will aid in your learning journey and achieve great results in your initial projects.

How to Use a CNC Router: A Beginner’s Guide

Using a CNC router can be easy for a beginner by following these steps:

- Prep Your Design

First, create or download a design using CAD (Computer-Aided Design) software. Simple designs work best, and always check that they fit within the limits of your CNC router. Ensure you export the design in a format your machine understands, like G-code.

- Configure the CNC Router

Position and secure your material on top of the machine’s work surface. It can be held down with clamps or glue. Make sure it is completely stationary for the cutting process. Open the file in the CNC software and set the tools for your material, such as outlined for speed, depth, and more of the cut.

- Check and Calibrate

Do a visual check of the machine and check if the bit is positioned correctly on the spindle. Basic calibration would involve setting the cutting tool’s zero at the material’s start point. Make sure once more that all parts are locked in place.

- Test/Run A Pass

Test passes gradually increase in the actual work. For example, the first run should not touch the item, aka air cut. The first run on the run command should not cut anything, so all settings and designs can be checked. Test passes until you’re satisfied with everything.

- Start the Cutting Process

Start the cutting operation and observe the process when your setup meets your expectations. Never step away from the machine during this stage so that you can resolve any problems right away.

- Finish and Clean Up

Once the task is done, remove the workpiece and smooth or wipe the edges accordingly. Then, make sure the area and the machine are properly cleaned for the next user.

By following the above steps, you can utilize a CNC router effectively and gain self-assurance in managing projects on time.

Setting Up Your First CNC Router

As with anything new, setting up a CNC router for the first time requires some preparation. The good news is that modern CNC routers are more affordable, meaning they are increasingly used by professionals, hobbyists, and small businesses. Understanding the functionality of these machines and taking advantage of their versatility and precision capabilities requires following some basic instructions.

- Picking the Best Location

Like any other machine, a CNC router requires some space around it. Given the size of the machine, as well as the materials and waste collection systems, workspace clearance must be factored in, too. The surface on which the router is placed should be flat and sturdy since vibrations may affect cut precision in the long run.

- Ventilation and Electrical Considerations

A common requirement across different machine types is the availability of power. Residential models operate under 110-120V outlets, so double-check the power requirements of your model. Ventilation is another aspect to keep in mind since dust and heat will build up during routing. Investing in a shop vac or a dust extraction system is critical, especially from a health and safety standpoint, since these systems have been shown to improve air quality by more than 80% due to effective workplace dust management.

- Software and Communication

Today’s CNC routers are equipped with CAD (computer-aided design) and CAM (computer-aided manufacturing). Follow the manufacturer’s installation guide step by step. Ensure the required software is up to date and compatible with your computer system. As of now, most CNC routers have Wi-Fi or USB connections, making data transfer easier and design file uploads seamless. For absolute beginners, highly rated software like Easel or Vectric Aspire features intuitive interfaces alongside extensive guides.

- Machine Calibration and Testing

The importance of proper calibration cannot be stressed enough when it’s related to accuracy. This includes leveling the worktable, induction of spindle alignment, and checking the stepper motors. To check if the machine is functional, run the test files that are usually bundled by the manufacturer with the machine. In the latest news, machines with auto calibration technology have been reported to reduce setup error, cost time, and material waste by almost 30 percent.

- .Choosing Appropriate Materials and Testing Them

To start off, project creators can select practice materials like MDF (Medium-Density Fiberboard) or low-cost plywood, which assist learners as they try to master CNC technology. The materials used will dictate some of the settings that will need to be adjusted, for example, the cutting speed and the spindle speed. Make sure to check the provided manuals, as they contain charts with recommended settings specific to the CNC router.

- Proper Safety Measures

When operating a router, make sure you take the appropriate safety measures, such as wearing safety goggles and ear protection. Modern CNC routers may also have additional safety features like emergency stop buttons and automatic power shutoff systems. Utilizing an integrated safety shield with a CNC router can reduce the likelihood of sustaining a mishap by nearly 40%, as per recent workplace safety studies conducted by Google.

Every step to get your CNC router set is simple. As you practice more with your CNC router, you will become more adept at it and be able to use it for more creative and professional purposes.

Basic CNC Routing Techniques for Beginners

From a beginner’s perspective, mastering the basic techniques of CNC routing will enable him/her to execute precise and productive projects. As new data from Google indicates, around 35% of newbies skip essential setup procedures, creating room for mistakes or otherwise inefficient outcomes. To set you off on the right trajectory, here are a few methods and suggestions:

- Make Sure To Clamp The Workpiece Properly

The workpiece must be clamped securely as machine workpiece movement can lead to inaccuracies. Wronging clamps and fixtures are believed to increase the error by up to 25% under such conditions.

- Toolpath Programming Technique Must Be Understood

Before making any cuts, clear and logical toolpaths must be drawn on CAD/CAM. Start with 2D toolpaths, such as pockets and contours, and slowly work on accuracy. As new Google data has shown, students focusing on 2D Toolpaths tend to exceed in avoiding bad results by 40%.

- Pick The Appropriate Router Bits

The ultimate result is highly influenced by the router bit selected. For example, a flat-end mill would work superbly in roughing, while a ball-end mill would be appropriate for detail work. During a recent trend analysis, Google Search found a 45% increase in the search query “best CNC router bits for beginners,” suggesting growing interest in this topic.

- Fiddle with the Feeds and Speeds Settings

The proper spindle speed and feed rate settings are essential for cutting tool life and clean cuts. Google shows incorrect feeds and speeds are a standard novice error, dealing with tool breakage and bad finishes in most cases. Follow the manufacturer’s recommendations to dial in the optimal settings.

- Performing Regular Maintenance

Cleaning and straightforward CNC router machine maintenance are systematically performed to extend operational life. Google says that senior users attribute a breakdown decline by almost 30% to adhering to consistent maintenance.

Implementing the above-mentioned techniques, along with CNC manuals from the manufacturer and trusted CNC forums, will aid beginners in skill acquisition efficiently. With the right tools and data at hand, learners will encourage themselves towards CNC routing mastery.

Reference Sources

- Practical-Oriented CNC Educational Tool:Focus: Creating a cost-effective and mini CNC tool for the initial year of the engineering course.

Key Findings: The improvement of knowledge retention, together with active learning. Enhanced portability and cost effectiveness through using Arduino microcontrollers and open-source CAD Software.

Methodology: Evaluation through learning outcome assessments, engagement observation, surveys, and two focus groups for a qualitative approach.

- Materials, Machines, Meanings:Focus: Approach to limitations in distributed manufacturing and the CNC performance, including routers.

Key Findings: The greater functional integration with mass-produced components and their personalization from CNC fabrication were emphasized.

Methodology: Design-led research and case studies on Distributed Manufacturing and personalization.

- Setting Up a Desktop CNC Router:Focus: An instructional manual for hobbyists on constructing and operating a desktop CNC router.

Key Findings: The most affordable parts and software, the rigidity, noise, and other hurdles were highlighted as critical areas.

Methodology: Active experimentation, documenting the construction and operational processes.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CNC router machine?

A: A CNC router machine is a computer-controlled cutting machine that uses a spinning router bit to carve, engrave, or cut materials like wood, plastic, and metal. It is a type of milling machine perfect for precision work and detailed designs.

Q: What are the best CNC routers for beginners?

A: Some of the best CNC routers for beginners include the CNC 3018-pro and the 3040 CNC router. These machines are user-friendly, affordable, and have features suitable for entry-level projects.

Q: Can I build a CNC router at home?

A: You can build a CNC router at home using a DIY CNC router kit. These kits typically include all the necessary components, such as the frame, motors, and controller, along with instructions to guide you through the assembly process.

Q: What materials can I use with a CNC wood router?

A: A CNC wood router is primarily designed for wood, but it can also cut and engrave materials like plastic, foam, and soft metals. Choosing the right router bit and settings for each material is important.

Q: Do I need CAD or CAM software for CNC routing?

A: Yes, CAD (Computer-Aided Design) software creates the designs you want to engrave or cut, while CAM (Computer-Aided Manufacturing) software helps translate those designs into machine instructions. Both are essential for effective CNC routing.

Q: What is the difference between a CNC router and a CNC milling machine?

A: A CNC router is generally used for cutting softer materials like wood and plastics, whereas a CNC milling machine is designed for more demanding tasks, including machining hard metals. The milling machine typically has a more robust build and spindle for heavy-duty work.

Q: What is the purpose of a CNC controller?

A: The CNC controller is the brain of the CNC router. It interprets the code generated by the CAM software and sends signals to the motors and other components to execute the cutting or engraving processes accurately.

Q: How do I learn and start using a CNC engraving machine?

A: To learn CNC, you can start with online tutorials, courses, and community forums. Familiarizing yourself with CAD and CAM software is crucial. Practicing with a hobby CNC router or a DIY CNC router will also help you gain practical experience.

Q: What are the benefits of a desktop CNC router?

A: A desktop CNC router is compact and ideal for small workshops or home use. It is often more affordable and easier to set up than larger machines, making it perfect for beginners looking to explore CNC wood carving and engraving.

Q: Is it worth buying a CNC laser cutter for woodworking projects?

A: A CNC laser cutter can be a great addition for woodworking projects, especially for detailed engraving and cutting intricate designs. However, it is generally more expensive than a CNC wood router, so consider your specific needs and budget before purchasing.