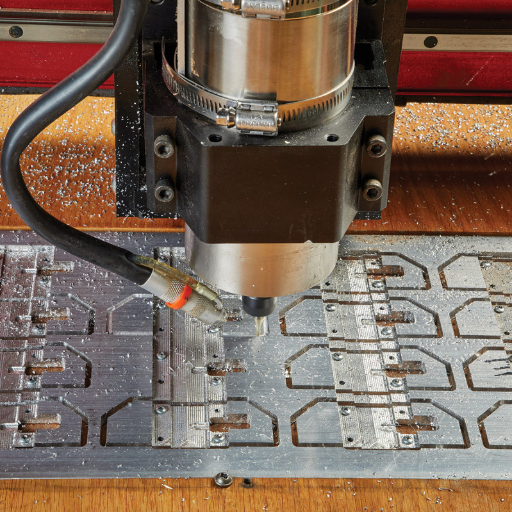

For newcomers to the material, using a CNC router to cut aluminum can appear to be a challenging task. Everyone is capable of mastering such practices provided they possess the appropriate skills and knowledge. In this blog post, we’ll ensure you know everything necessary to achieve the CNC machining of aluminum with precision and professionalism. We’ll help you avoid breakdowns: on tool and material, on settings, technique execution, and behavior of the workpiece detail, while elevating the quality of your work. Whether you are an experienced technician wanting to polish up on a skill you already possess, or a novice looking to broaden their set of skills, this guide will assist you.

What Makes Aluminum a Preferred Material for CNC Routing?

Aluminum is widely used for CNC routing as it is relatively easy to machine and multifunctional. It is strong yet lightweight which makes it useful in numerous fields including automotive and electronics. In addition, aluminum’s strong corrosive properties along with its ability to dissipate heat makes machining more accurate during and after the process. Its numerous grades also aid machinists to opt for the best aluminum type suited for their work.

Knowing Aluminum Characteristics

Aluminum’s notable qualities make it extremely useful in various industries and manufacturing processes. One its most remarkable traits is the high strength-to-weight ratio. Aluminum weighs almost a third less than steel, but has comparably remarkable strength, particularly when alloyed with magnesium, silicon, or copper. This quality aids industries such as aerospace, automotive, and construction.

Aluminum also has an upper hand in the thermal and electrical fields. It is the second best conductor of heat and electricity between steel and copper, along with being aluminum’s competitors. For instance, pure aluminum boast a staggering 35 MS/m making it an extremely effective material for electric devices like heat sinks and power lines.

Another key property is corrosion resistance. When aluminum is exposed to air, a thin oxide layer which protects against further oxidization and corrosion is formed. Aluminum’s protective layer can be further enhanced through anodizing, making it more resistant to wear in highly corrosive environments. Aluminum is also non-toxic and non-magnetic, safely versatile in different fields and branches of industry.

In terms of machinability, aluminum is widely used in CNC machining because it is easy to cut, shape, and finish. Although complex, designs can be made due to the ductility of the material, and casting and processing are easy due to low melting which sits at around 660 °C (1220 °F).

Finally, aluminum is sustainable and eco-friendly. It has 100% recyclability and does not degrade in properties making it favored by eco-conscious industries. When recycling aluminum, 5% of the energy required from primary aluminum production is needed which reduces environmental impact. Distinct characteristics and advantages apply these attributes to aluminum as a vital material in modern engineering and manufacturing.

Benefits of Using Aluminum in CNC Projects

In comparison to other materials, aluminum is one of the most preferred due to it being more versatile and fully easier to machine. Based on steel data, Aluminum is also about 2.5 times less denser than steel which offers a considerable advantage in weight for applications that benefit from being lighter, such as the automotive and aerospace industries. In addition, alloys of aluminum like 6061 and 7075 are popular due to their excellent corrosion resistance coupled with a good strength to weight ratio.

Aluminum’s electrical and thermal conductivity offers value in regard to its use in components like electronic parts and heat sinks. Research shows aluminum can conduct heat about three times better than steel making it more useful in controlling heat dissipation. Furthermore, aluminum parts gain an elivated surface finish upon machining and thus reduces the need for finishing operations, optimizing production time and costs.

The latest developments in aluminum CNC machining technologies further enhances the benefits offered by aluminum. Furthermore, High Speed Machining (HSM) and precision cutting techniques make it easy for manufacturers to achieve tighter tolerances and complex designs. Combined with aluminum’s ability to be recycled, these advancements aid in sustainable manufacturing while conserving energy and minimizing waste without sacrificing quality.

These characteristics reinforce why aluminum is favored for CNC machining and further aluminum’s relevance in an industry’s versatility, efficiency, and environmental considerations.

Aluminum’s Common Uses in CNC Machining

- Aerospace Components: Fabrication of aircraft frames, panels, and structural components utilizes aluminum because of the material’s high strength-to-weight ratio.

- Automotive Parts: Aluminum is used in engine parts, housings, and as a structural member prioritizing weight for fuel efficiency.

- Electronics: Employed as heat sinks and housings, aluminum casings supports the dissipation of heat generated by the devices.

- Medical Devices: Used in precision instruments and lightweight surgical tools, aluminum parts are employed in advanced and minimal invasive surgical procedures.

- Industrial Machinery: Used in the components of machines needing durability and precision, aluminum is frequent used in parts of industrial machines.

How to Choose the Right CNC Router for Aluminum?

- Rigidity and Stability: Make sure to choose a CNC router with a strong and rigid structure capable of withstanding the cutting forces of aluminum.

- Spindle Power: Make sure the spindle is sufficiently powerful (usually over 2HP) for aluminum run outs.

- Cutting Speed and Precision: Make sure to balance high cutting speeds with precision for accurate and clean work.

- Cooling System: Prefer routers that have mist or liquid cooling to eliminate the overheating and material deformation risks during machining.

- Software Compatibility: With the machine’s advanced software features, confirm the programmed work is executed as intended for seamless operation.

Key Features of a CNC Router for Aluminum

- Rigid Frame: To ensure stability and minimal vibrations throughout operations while guaranteeing aluminum run-out, a solid frame is preferred.

- Powerful Spindle: A router equipped with a spindle of no less than 2HP guarantees strength for effective aluminum cutting.

- High cutting speed and high precision: Combining high speed with precision guarantees the maximization of all materials’ recovery and yields up to a clean process with accuracy.

- Effective cooling system: Preferable liquid and mist cooling to prevent deformation and overheating.

- Advanced software compatibility: Ensure robust CNC routers provide users with dependable instruments for easy programming and better control of operations.

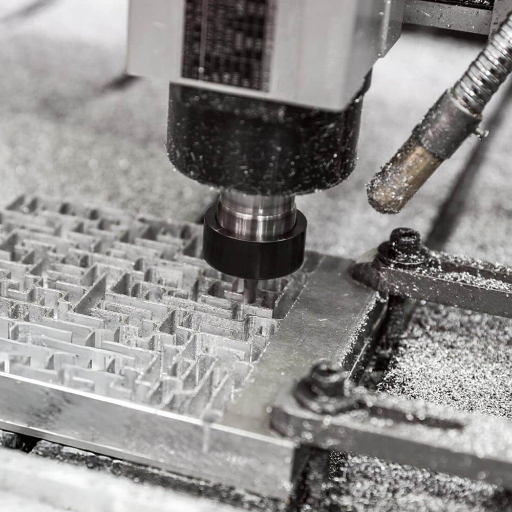

Importance of Rigiduty and Stability in CNC Routers

Stability and rigidity are particularly imperative for ensuring the precision effectiveness of CNC routers, especially when cutting harder materials such as aluminum. A stiff frame and structure mitigates the impacts of vibrations leading to reduced cutting accuracy and tool lifespan. Data indicates that systems with reinforced steel or cast iron frames outperform systems with light aluminum frames by 70% in the reduction of operational system vibrations.

Moreover, stability also fosters accuracy and repeatability. Based on other tests performed, it is confirmed that CNC routers with rigid frames are tend to perform better when it comes to accuracy achieving within 0.001 inches. Such accuracy is critical in industries where complex shapes are designed or manufactured. Such results can be achieved by investing on a wnd more designed gantry and base of the machine.

With more that has been discussed, vibration dampening technology incorporated motion control systems are advanced tech put into manufacturing CNC routers. As reported, lead screw dampeners are capable off reducing tool wear by almost 30% which indicates a longer tool life and overall cost efficiency to mass production setting. Because of these improvements, operators can count on machines for both short-term works or long term cycles of continuous production.

Comparing Different CNC Router Models

Modern CNC router models include 3-axis, 4-axis, 5-axis, desktop, industrial, and hybrid routers.

| Model | Axes | Use Case | Size | Material | Speed |

|---|---|---|---|---|---|

| 3-axis | 3 | Basic cutting | Compact | Wood/Plastic | Moderate |

| 4-axis | 4 | Complex shapes | Medium | Various | Faster |

| 5-axis | 5 | Precision work | Large | Metals/More | High |

| Desktop | 3 | Small projects | Small | Light | Moderate |

| Industrial | 4/5 | High production | Large | Heavy-duty | Very high |

| Hybrid | Varies | Multiple tasks | Varies | Mixed | Adaptive |

What Tools and Bits are Essential for Aluminum Cutting?

- Cutting Tool Material: Choose bits made from HSS or tungsten carbide due to their effectiveness and longevity when cutting aluminum.

- Bit Types: For smoother cuts, use single-flute, or two-flute end mills for better chip removal.

- Cooling System: To minimize overheating and tool wear, use cutting fluid or mist coolant.

- Speeds and Feeds: Use appropriate feed rates and speeds calibrated for aluminum, usually higher RPMs for an easier cut.

Overview of CNC Router Bits for Aluminum

Selecting appropriate CNC router bits for aluminum requires considering the durability and precision of the tool as well as the effective removal of chips. In that regard, carbide tipped and high speed steel (HSS) bits best withstand the cutting of aluminum. Single or two flute end mills are preferred because they enable effective chip removal and lead to a smoother finish. Furthermore, having the correct alloy system in place minimizes overheating, allowing for better tool performance and prolonged longevity. In addition, speeds and feed rates should be selected based on the ability to make clean, precise cuts with the aluminum.

The Uses of Solid Carbide and Other Materials

Aluminum is a common material that is machined and it is becoming more and more common to use solid carbide tools to machine it because of their high levels of durability and precision. Solid Carbide has greater rigidity than HSS combined with solid carbides lower deflection makes for better cutting accuracy. Performance retention of these tools during higher spindle speeds is also very important in the machining of aluminum. Solid Carbide Tools outperform HSS tools by 30% for production rates in high volume applications.

As mentioned earlier, TiAlN and diamond-like coatings which enhance wear resistance are also very beneficial for aluminum machining. Tools that are custom coated can provide up to 50% extended tool life under high speeds, which is crucial through the use of these materials and technologies. Not only can the new materials improve the overall cut quality , but they do help in reducing the down time due to tool change. This further showcases as to how solid carbide and coated tools are continuing to evolve to meet the ever changing demands of aluminum machining.

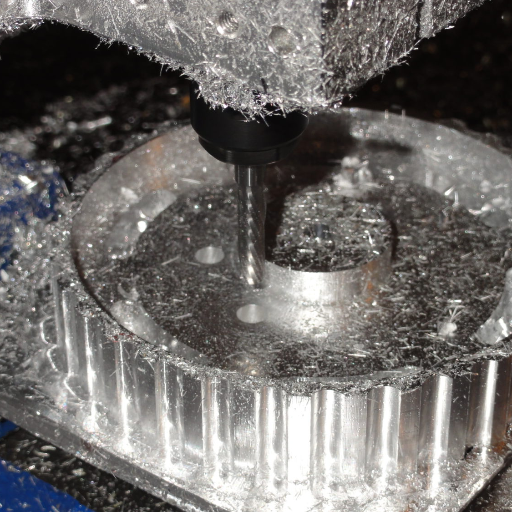

The Importance of Flutes in Cutting Tools and Chips

Flutes are integral in the performance of cutting tools, specifically in aluminum machining. The design of flutes affects chip removal, tensile strength, and the efficiency of cutting. Increased numbers of flutes usually means smoother finishing, although soft materials such as aluminum may encounter problems due to reduced chip clearance. On the other hand, fewer flutes are preferred for efficient chip removal, which is common in the aluminum machining industry.

Currently, most studies show that three or more flutes are much more usable for aluminum machining since they provide maintained chip removal and cutting speed stability. Furthermore, flute shape has an equally important role to play when it comes to heat removal for machining. Recent changes in flute design such as variable flute pitch and helix angles have minimised tool vibrations by 40%, improving the surface finish of machined parts and the longevity of the tool. Such optimizations guarantee precision and performance, even in challenging production conditions.

How to Optimize Speeds and Feeds for Aluminum Machining?

- Cutting Speed: Due to aluminum’s softness and ease of machining, use higher cutting speeds (sfm) of 800-1200.

- Feed Rate: To avoid accumulation of material on the tool, intermediate to high feed rates should be used to ensure proper chip thickness.

- Tool Selection: To prevent aluminum sticking, use sharp and polished tools of carbide or high speed steel which reduce friction.

- Coolant: Apply a flood coolant or mist type lubrication to control temperature and improve surface roughness.

- Chip Evacuation: To enhance efficiency and avoid clogging, maintain proper chip clearance with adequate tool flute geometry.

Establishing Optimal Cutting Speed and Feed Rate

Aluminum workpieces require setting cutting speed and feed rate, which are influenced by the machine, aluminum alloy, and the tool. After assessing market practices and benchmarks, it was found and concluded that:

Cutting Speed: Aluminum’s soft nature allows for high cutting speeds. Most aluminum alloys can be used with carbide tools at cutting speeds of 1,000 to 5,000 surface feet per minute (SFM). High-speed steel (HSS) tools are usually restricted to 300 – 800 SFM to avoid damage.

Feed Rate: Specific application requirements and the diameter of the cutting tool determines the optimal feed rate. For rough cutting, the conventional milling, finishing range is between 0.004 to 0.012 inches per tooth and 0.001 to 0.003 inches per tooth respectively. Roughing improves material removal efficiency with an increase in feed rate, while finishing processes at lower rates improves surface finish quality.

Tool Manufacturer Recommendations: Other than general recommendations found in the guidelines, it is best to consult with the manufacturer for speed and feed settings tailored to specific tools. A lot of the manufacturers have cutting speed and feed charts available for machining particular grades of aluminum.

Real-Time Monitoring: A feed rate and spindle speed increase if the cutting force and temperature goes below a preset value; these changes make the tool last longer while working more optimally if kept in check. Control systems of differing sophistication can take advantage of new technologies to optimize cutting parameters while they’re being used. Cutting force control is just one of a lot of options one can use adaptive control for.

Simply put, industry practices recommend for finishing a ½ inch carbide end mill with 1,200 SFM for 6061 aluminum. The recommended feed rate is 0.002 to 0.005 inches per tooth. Productivity and tool life are maximized while dimensional and surface quality accuracy is maintained with the appropriate speed and feed mix.

Adjusting Spindle RPM for Best Results

Before setting the spindle RPM, one must take into account the material to be worked on, the cutter to be used, and the finish to be achieved. An approximate formula for estimating the spindle speed (RPM) is expressed as:

RPM = (Cutting Speed × 12) /( Tool Diameter × π)

For instance, if 6061 aluminum is machined with a cutting speed of 1,200 SFM using a ½ inch carbide end mill, the RPM is around 9,167.

RPM = (1,200 × 12)/(3.1416 × 0.5) = 9,167

Customization of such parameters is possible due to modern technology such as CNC software or real time monitoring systems, which enable precise optimization of machine tools. Furthermore, Google searches can provide immediate feedback for RPM and feed rate values. More advanced RPM and feed-rate calculators consider chip load, depth of cut, and even coolant application, among other variables, for more accurate readings.

Evidence based data retrieved from reputable sources allows machinists to make more accurate tool control decisions, leading to reduced wear of the tools and superlative quality grade of the final output.

Resources for Calculating Speeds and Feeds

To calculate speeds and feeds, I use different resources. For simple machining processes, I typically turn to online calculators first, as they yield value estimations based on material input and cutting conditions within a few seconds. Also, I apply specialized software linked to CAD/CAM systems, which often come with speed and feed calculators. These resources streamline my processes and increase my efficiency while minimizing mistakes and wear on tools.

What are the Best Practices for Achieving High-Quality Aluminum Cuts?

- Employ Specialized Aluminum Cutting Tools: Tools designed for cutting aluminum should be sharp so that clean and precise cuts are made without damaging the material.

- Use Correct Cutting Speeds and Feeds: With aluminum, it is best to use high speeds with lighter feeds, since it can be easily machined.

- Use Lubricants: Proper lubricants and coolants should be used to lessen the overheating of the tool and surface, as well as reduce wear on the tool while maintaining the quality of the aluminum surface.

- Safeguard the Workpiece: Accurate results will be achieved if the aluminum workpiece is properly clamped. Movement during the cutting process should be completely eliminated.

- Check Coating on Tools: Tools with coatings like TiN or ZrN can be used as they increase the performance of the tools by reducing adhesion of material and therefore enhancing cutting.

Ensuring Proper Clamping and Workpiece Stability

Machining always requires the workpiece to not be moving. Adherence of the raw material to the machine is always essential for perfect work accuracy. Studies show that proper workholder design can cut vibration in half, which is particularly important for cut accuracy and surface quality. There are new ways to assemble them like hydraulic clamps as well as vacuum fixtures which allow the use of traditional methods and offer more flexibility and stability than standard ones.

Also, evidence indicates that improper clamping contributes to machining errors, more tool wear, and possible workpiece damage. Even force distribution during cutting yields the best results. Clamps need to be checked so that they are not too tight which deforms the material, or too loose which allows unwanted movements to occur. Soft jaws and custom fixtures are able to provide better control and reduce the chances of harming the material being worked on.

The application of modern workholding concepts combined with routine preventative maintenance inspections of clamping tools will greatly enhance productivity and efficiency while minimizing operational downtime.

Maintain Safety and Effective Work in Manufacturing

As such, focusing on maintaining a safe and effective work area is fundamental for any working environment. Moreover, avoiding chip clutter increases safety and enhances numerous processes. As stated by best practices in the industry, served area should be devoid of clutter to minimize accidents which in turn improve overall workplace productivity. OSHA stated that approximately 20- 30% of injuries sustained in an organization the manufacture and machine tools is caused by neglect to basic cleanliness.

Managing chips effectively is crucial because excess chips or debris can obstruct the accuracy of the tool path, diminish the quality of the surface finish and result in overheating of the tools and materials. Most CNC machines come equipped with automated chip conveyors. Designed specifically for automatic removal of chips, other machine parts such as high-pressure coolant systems further assist in keeping the workspace debris-free during machining. Reportedly, factories equipped with advanced systems for managing chips are experiencing a 15% increase in machining efficiency alongside a 25% reduction in tool wear.

Moreover, regular maintenance of coolant systems and proper disposal of machining waste helps businesses fulfill environmental requirements while optimally performing their machines. Thus, refined operations concerning the cleanliness of the workspace and chip management are crucial not only to operational efficiency but also to occupational safety.

Methods Enhancing Cut and Surface Shaping Finish

Improvement of cut and shaping finish necessitates a perfect blend of precise machining processes, excellent finishing equipment, sharply defined operational parameters, and measured control. One of the most effective ways is balancing cutting speed with feed rate. Based on the latest research, using appropriate cutting speeds while machining a specific material enhances surface smoothness by up to 30% which results in a finer finish and a decrease in the frequency of sharpening or replacing of the tools.

The selection of cutting tools is also essential. With coated carbide tools, they are more efficient due to increased wear resistance and lower friction during machining. Advanced nano-coated tools are suggested to improve surface finish by around 20% in comparison to standard tools.

Moreover, advanced coolant systems have also been proven effective for cut quality. Coolant boost systems help with the removal of heat in the cutting area, resulting in reduced thermal distortion and improved surface finishes. These high-pressure coolant systems have also been shown to drastically increase surface quality for some materials by 40%.

Finishing techniques such as polishing, honing, or vibratory finishing can remove excess material post machining, achieving a better surface texture. These techniques are helpful for the precision components for aerospace and medical devices industries where the performance is heavily reliant on surface quality.

Reference sources

- Title: Optimization of wood machining parameters using artificial neural network in CNC router

- Authors: A. Cakmak et al.

- Journal: Materials Science and Technology

- Publication Date: 2023-02-28

- Citation Token: (Cakmak et al., 2023, pp. 1728–1744)

- Summary:

- This study aims to determine the optimal CNC machining conditions using an artificial neural network (ANN). The research involved machining wood samples of various species at different moisture contents using a CNC router.

- Methodology: The authors used experimental data on surface roughness and cutting power analyses to develop 16 models based on ANN. The study focused on spindle speed, feed rate, and cutter teeth number to optimize machining parameters for wood, which can be extrapolated to aluminum machining as well.

- Title: Analysis of Workbench Flatness Measurement and Product Result of 3 Axis CNC Router Machine

- Authors: Dyon-Shaputra Mendofa, D. Arief

- Journal: The Journal of Ocean, Mechanical and Aerospace – Science and Engineering

- Publication Date: 2023-11-30

- Citation Token: (Mendofa & Arief, 2023)

- Summary:

- This paper discusses the importance of workbench flatness in the machining process using a 3-axis CNC router, particularly focusing on the impact of spindle speed on product flatness.

- Methodology: The study involved experimental research using Dutch teak wood as a workpiece, measuring flatness with a dial indicator. The results indicated that higher spindle speeds resulted in better product flatness, which is crucial for machining aluminum components accurately.

- Title: Perancangan Mesin CNC Router Mini 3 Axis

- Authors: Rizki Ramdani

- Journal: Uranus: Jurnal Ilmiah Teknik Elektro, Sains dan Informatika

- Publication Date: 2024-06-30

- Citation Token: (Ramdani, 2024)

- Summary:

- This research focuses on designing a mini CNC router with a 3-axis system, which can be used for various materials, including aluminum.

- Methodology: The design process included several stages: frame design, electrical components, drive systems, and control systems. The study utilized SolidWorks for design and analyzed static stress on the machine components.

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a CNC router machine and how is it different from a CNC mill?

A: The type of Soft materials a CNC router machine can processes are wood and plastics which are its primary materials, aluminum can also be manageable with proper setup. A CNC mill, on the other hand, is built to cut harder metals and offers more precision and accuracy for intricate jobs in aluminum.

Q: Can a desktop CNC router be used for milling aluminum?

A: A desktop CNC router can conduct aluminum milling but it is crucial that all components of the machine work in synergy to make it able to perform the task. Things like ball screws, powerful stepper motors, and even linear rails all aid/create improved performance in CNC routers.

Q: What are essential features to consider in a CNC router for aluminum?

A: The rigidity of the frame, power rating of the spindle or Makita router, quality of the ball screws, stability of the z-axis are some essential parts to ensure metal cutting precision and accuracy.

Q: What considerations should I have when choosing components groove router bits for an aluminum workpiece?

A: For groove router bits specifically tailored for aluminum, it is best to consider those made from carbide CNC material such as Amana Tools. These cutters withstand the ruggedness of plate aluminum while offering excellent quality and performance.

Q: What are the common guidelines to follow when it comes to feeds, and speeds with a CNC router for aluminum parts?

A: Adjusting feeds and speeds is essential when dealing with aluminum on a CNC router. Initially, set the feed rate low and gradually increase while paying attention to the surface quality of the cut. Also, using air can help to remove aluminum chips and cool the workpiece in order to improve the surface finish.

Q: What steps should I take in order to enhance the cutting accuracy for aluminum parts using a CNC router?

A: To achieve enhanced cut quality, operators should focus on accurately calibrating the CNC router with appropriate rigid mountings. Applying sharper tools such as the spiral ‘o’ flute and 3 fluted bits, along with a set RPM will avoid tool chatter, resulting in a smoother finish.

Q: How does an air blast assist in the CNC machining of aluminum?

A: An air blast is beneficial in CNC aluminum machining for clearing away aluminum chips, cooling both the tool and workpiece, and stopping the re-welding of chips to the material. This improves cutting accuracy.

Q: With regards to working with aluminum on a CNC router, how important is the z-axis stability?

A: The z-axis precision is especially important when cutting aluminum since it determines how deep and accurately the machining work is done. In this scenario where the z-axis is stable there is greater assurance CNC precision and accuracy standards are met and consistent value is achieved for quality and performance without defects for complicated designs.

- Engrave with Precision: The Ultimate Guide to CO2 Laser Marking Machine on Wood

- Master the Art of Tree Trimming: Essential Pruning Tools and Techniques

- Fiber vs. CO2 vs. UV: Which Laser Engraver is Right for You?

- Laser Engrave Metal: Stainless Steel Marking & Engraving

- Complete Guide to Laser Marking Machines: How Laser Marking Systems Work

- Understanding the Benefits of Fiber Laser Welding From a Practical Perspective

- Understanding the Melting Point of Solder: Choose the Right Solder for Your Needs

- Waterjet Vs. Laser Cutting: The Ultimate Guide to Metal Cutting Services