CNC engraving and laser engraving are two very prominent methods of modern engraving employed in numerous fields. Even though both methods are accurate and efficient, they are quite different in their procedures, uses, and results. In this article, we will discuss the most important differences of these processes so that the readers could grasp the relative merits and demerits as well as the ideal scenarios for employing each method. This guide should serve as a valuable tool for manufacturers, designers, or anyone interested in sophisticated engraving technologies, highlighting crucial distinguishing characteristics of CNC and laser engraving.

What are the Main Differences Between CNC Engraving and Laser Engraving?

CNC engraving employs mechanical elements to etch or sculpt out lines which extremely soft engraving depth and molding mid-range materials like metal or wood. Whereas, laser engraving uses a laser focused beam to vaporizing material surfaces, yielding the greatest detail like very fine lines but not depth.

Both methods hold very many types of materials but CNC engraving is more effective with harder materials, while laser engraving works better with lighter delicate items such as glass or paper and more complex designs.

Due to the non physical means of work, Laser engraving is much faster for most works, especially complex ones. CNC engraving is faster for heavy duties tasks and slower for everything else.

CNC engraving machines are usually faster to laser engravers and are of lower maintenance, but CNC machines require a lot of maintenance due to tool servicing. These machines also have much lower servicing difficulties but having advanced laser parts means expensive servicing.

CNC engraving is the best option for industrial works as it does signs and sells products while manufacturing and maintaining the products seamlessly. Laser engraving excels at anything involving personal gifts, intricate detailing, and soft sensitive materials.

Understand the Machine Basics

Before selecting either CNC laser engraving choice, keep in mind the material, how precise the work should be, and the purpose of the work.

CNC engraving is the better method with use of industrial works due to how accurate it is with depth. On the other hand, laser engraving is better used for softer materials or items because they are able to capture the intricate details. Think of the requirements of your project before choosing a method.

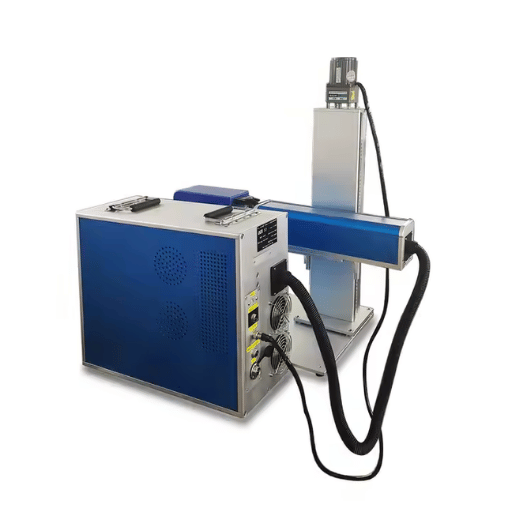

Working Principles of the Laser Engraver

In its most basic sense, a laser engraver uses a laser as the marking tool and uses computerized designs. It is essential to highlight 3 main components like the laser source, work surface, and controller. The first as the laser source produces the light, while the other two define the type of engraving.

Like any other equipment, laser engravers have minimum standards and benchmarks set on the usage of the device. These benchmarks include the perforating speeds as well as power consumption, which on average, is about 30W to 100W. Perforating speeds were further recorded with a maximum capability of 1,200 inches per minute (ipm). As a concrete example, a 30W laser can be used with engraving wood or acrylic and should achieve a depth of roughly 0.02inches per pass. Higher powered lasers reaching might go beyond the range of 0.1 inch engraving on stainless steel or aluminum.

The precision of laser engravers is critical, with the majority of devices attaining a resolution of 500 to 1,000 dots per inch (dpi). This is more than enough for complex designs. Enh advanced models, autofocus mechanisms and cooling systems are included to fine tune accuracy and prevent overheating during prolonged working periods. These data points emphasizes how adaptbability laser engraving is for various materials and uses.

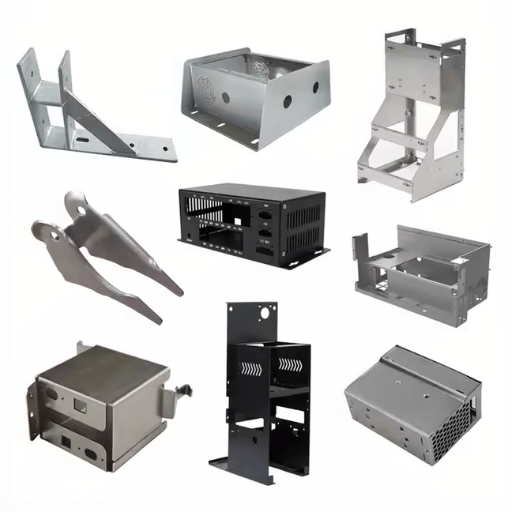

What is a CNC Engraving Machine

CNC engraving machines are multifunctional devices tailored to suit a variety of engraving tasks. A detailed description of each feature is listed below.

- CNC engravers are some of the most precise machines available, high grade CNC engravers achieve upwards of ±0.01 mm precision.

- These machines are universal as they can engrave on metals such as steel, aluminum, brass, plastics, wood, glass and more which allows use in many industries.

- Most CNC engraving machines have spindles with variable speed control, with speeds of 10,000 to 50,000 RPM, to suit the density of different workpieces and achieve the best results.

- These machines are easily programmable with design imports and customization options due to the integrated software and interfaces.

- Streamlined ATCs are included in some models, which smoothen out the multi-tool steps needed in the complex engraving workflows, thus enhancing productivity and decreasing the time needed for setup.

- The CNC engravers are built with sturdy frames made of cast iron or steel, which minimizes the vibration and enhances stability and consistent performance.

- To control the heat resulting from extended periods of operation, plenty of the machines are fitted with liquid or air cooling systems, which improves the life span of machine parts and precision.

- Some systems such as dust vacuuming systemowm or rotor dust cilia integrated into the machines improve the cleanliness of the workspace by eliminating contamination and enhancing the workspace view.

- Emergency stop buttons as well as protecting shields and error detection sensors to prevent harm to the machine itself and accidents during operation multifunctional protective measures are adopted in many machines.

- Modern CNC machines accept both 2D and 3D designs, so they can engrave and relief as required which adds value since it caters for both flat and dimensional engravings.

Which Engraving Machine Should You Choose?

Benefits of Laser Engraver Systems

Laser engravers are perfect for many applications because of their effectiveness, speed, and flexibility. Their prowess in watermarking comes from the technology achieving astonishing units of measurement like micrometers of accuracy. The engravers work on diverse materials such as wood, acrylic, metal, glass fabric and many more. With modern advancements, laser systems are integrated with cutting edge software that seamlessly meld design files into the workflow, and automate processes which drastically reduces production times while ensuring constancy of quality. In addition to this, several modern laser engravers come with features like eco-friendly power sources and energy-saving technologies, which lowers the overall costs while also greatly aiding sustainability. Lastly, the engraver’s non-contact technique ensures low abrasion on tools and materials, which maintains the condition of the workpiece aiding equipment longevity.

Benefits of the CNC Router

CNC routers offer a solution for complex geometry due to the highly accurate cuts that it offers through the computer-aided mechanism, minimizing error margins to almost zero.

- CNC routers are versatile, allowing for numerous applications because they are capable of working with different materials such as wood, plastic, aluminum, composite as well as soft metals.

- CNC routers high-speed operations allow for extended periods of continuous work, greatly decreasing the time required to finish a project.

- Manufacturers can achieve the required output effortlessly with the help of CNC routers, which provide uniform reproduction of identical components, ensuring consistent quality in production.

- Production costs are minimized with CNC routers as the precision cutting capabilities offered by these tools reduces material waste.

- CNC routers paired with CAD/CAM software eliminate design change steps and work sequentially, ensuring that intervention is reduced, allowing for automation.

- CNC routers are an economical solution in the long term; despite the greater initial investment, they result in lower expenses due to reduced need for manual supervision, faster job completion, and less waste.

- The automated and sealed design of most routers makes them easier to use and reduces the chances of workplace injury, operator attendance to the machine’s processes is also greatly reduced.

- These machines support the creation of one-off prototypes as they offer flexible custom programming to match precise project requirements.

CNC routers are constructed with industrial-grade components, making them optimal for heavy-duty work over long periods. This feature, alongside other factors, ensures the high return on investment in these machines.

Things to Take Note of When Purchasing a CNC Machine or Laser Cutter

Thinking of purchasing a laser cutter or a CNC router requires weighing the operational costs, versatility with the materials, and key performance indicators (KPIs). While CNC routers dominate when it comes to cutting wood, plastics, and metals, into precise shapes, achieving cutting depths of 4 inches and greater, their counterparts, laser cutters, provide unparalleled precision with tolerances of about ±0.001 inches, perfect for intricate designs on soft materials like paper, acrylic glass, and thin metals.

With both tools serving distinct purposes, operating costs are vastly different. CNC routers are more economically efficient since they only require a replacement of the spindle bearings and cutting tools over time, but their operating costs drastically increase when the used materials are harder and more frequently used. Lasers also have another hidden operating cost—maintenance of the laser components. The tubes alone require severe maintenance as the quality and type of laser installed greatly dictates its life expectancy of anywhere between 1,000 and 10,000 hours. Whatever the case may be, the energy productivity of both systems should be reviewed equally. While routers are considered low energy, later laser cutters can have their power consumption peak at 10 kWh, making them burdensome.)

In the end, the individual use case, spending limit, and required material flexibility should lead the decision. Companies dealing with various materials may find a CNC router’s versatility useful, whereas tailored cutting and engraving industries may prefer a laser cutter for its efficiency.

What Materials Can Be Used with CNC and Laser Engraving?

Engravable Materials by Laser

A diverse range of materials are available for laser engraving, wood, glass, acrylic, plastics, leather, to certain metals. It works best on softer, non-metals, as well as metals with a coating. Some materials such as PVC or particular synthetics should be avoided because they produce dangerous gas when engraved. Check the material and system compatibility before any further steps to guarantee efficiency and safety.

Materials Engravable with CNC Machines

The engraving capabilities of CNC machines for different types of materials are virtually endless, however their limits must be understood in order to efficiently utilize them. Below is an overview concerning effectiveness by material:

Wood: All forms of wood work best with CNC machines, both hardwoods such as maple and oak and softwoods like pine. The expected engraving depth averages between 0.5 mm to 3 mm depending upon the tool settings and make-up of the material being used.

Acrylic: Known to produce high clarity engravings, acrylic is perfect for polishing. Furthermore the processing speed can reach as high as 500 mm/min with intricate details done at slower feed speeds.

Glass: Cutting or engraving glass requires specific tools, like diamond-tipped engravers, to avoid cracking or chipping. The etch depths are usually shallow, 0.2 mm to 0.5 mm deep, which is heavily used for decorative purposes.

Leather: Laser engraving produces sharp, permanent marks on leather while retaining the material’s pliability. The precision of engraving varies with the type and thickness, as many tend to focus on avoiding burning or discoloration sight.

Plastics: Plastic materials such as polyethylene or ABS are friendly to CNC engraving and can be used for industrial and decorative purposes. They do pose a challenge since their melting threshold can be easily reached if the spindle and feed rates are set too high.

Metals: Coated metals like anodized aluminum or brass are perfect for CNC engraving since they allow intricate detailing without excessive wear on the cutting tools. Pure metal surfaces, like steel, go through a tougher-altering process and may require special tooling to receive engravings.

Data Tip: It is advised for one’s engraving machines to test indescriminately on small patches of elusive materials due course engraving to save time and adjust optimal settings for the work needed. Further more default software parameters for etching grade inputs like feed rate, spindle speed, and cut depth ensure consistent desired outputs and professional grade for different materials on each run.

How Does Laser Cutting Differ from CNC Milling?

Comprehending The Process Of Cutting With A Laser Beam

The distinction between laser cutting and CNC milling lies in the method of shaping the materials. Laser cutting works with a concentrated beam of light to cut or engrave materials using heat for the cutting edges. On the other hand, CNC milling cuts the materials with the use of mechanical instruments like spinning cutting bits that do a subtractive action. In general, laser cutting is best for non-contact work and intricate patterns while CNC milling helps with depth and precise three-dimensional shapes. Though both methods provide precision, they differ in material attributes and intended results.

An Overview of Advanced CNC Milling Processes

CNC milling is built on the basis of computer-controlled rotating cutting tools which cut and shape a workpiece. Important parameters that influence the quality and productivity of CNC milling operations include:

Spindle speed denotes the rotation speed of the cutting tool and is measured in rotations per minute (RPM). For most cases, spindle speed is between 1000 RPM and 20,000 RPM, where faster speeds are more suitable for softer materials such as aluminum, while slower speeds are optimal for harder materials like steel.

Feed Rate: This is defined as how quickly the tool moves across the given surface and is measured in inches per minute (IPM) or millimeters per second. Lower feed rates are suitable for more detailed precision cutting, while higher rates fit rough cutting.

CNC milling also boasts efficiency in maintaining tight tolerances achieving within ±0.001 inches (±0.0254 mm). Such accuracy is essential for high precision aerospace and medical devices components to ensure they meet operational requirements.

Cutting Tools: End mills, face mills, and ball mills cut various geometrical shapes such as flat surfaces and deep cavities.

Tool Material: Tools are made from different materials such as high speed steel (HSS), carbide, and ceramic because they have varying levels of durability, compatibility with the material, and purpose.

Metals, such as aluminum, brass, and titanium alongside polymers like ABS and polycarbonate, as well as composites, can be used in CNC milling because it is adaptable. The hardness and ductility of the material will determine the cutting tool needed and the machining parameters.

With precisely defined benchmarks, manufacturers can ascertain CNC milling optimization regarding setting adjustment for speed, pace, precision, and alignment with the project’s defined parameters. The parameters also aid in uniform quality in batch production, upholding consistency needed in engineering and manufacturing industry standards.

What Are the Advantages of Laser Engraving?

Precision and Efficiency of Laser Engraving

Laser engraving has unique advantages that have made it a preferred method of operation in different fields. Given below are the details of the benefits of laser engraving:

As one of the most advanced technologies, laser engraving provides extreme accuracy with its results. It is possible to achieve tolerances in the range of micrometers. For such reasons, laser engraving is perfect for fine jewelry, electronics, medical equipment, and other designs that are high detail.

As noted, modern laser engraving machines are fast. They can do large scale projects in short periods of time. This increases productivity and yields shorter lead times in the rest of the processes related to manufacturing.

Lasers are capable of carving engravings that are tough against wear, heat, and corrosion, which makes them ideal to use for things such as barcode markings, serial numbers, and safety labels that require precise detail.

Laser engraving is suitable for a wider range of materials like metals, plastics, glass, ceramics, and even organic substances like wood and leather, making this technique embrace countless possibilities and ideals in the manufacturing world.

Laser engraving is a non-contact procedure. Therefore, it does not cause any form of mechanical wear to the machines and also prevents the process from damaging fragile or sensitive materials.

Compared to traditional engraving, which uses tools, engraving with a laser requires no maintenance whatsoever. Operational costs are lowered even more because lasers do not require consumable materials such as chemicals and inks.

The eco-friendly nature of laser engraving stems from no waste or chemicals being used during its processes. It ensures compliance with strict environmental regulations in industrial applications.

Advanced laser engraving systems incorporate CAD software which allows intricate designs to be done easily. Personalization and differentiation is further supported through this flexibility.

Utilizing these benefits, laser engraving excels in performance for diverse artistic, engineering and manufacturing disciplines. The blend of material compatibility, precision and agility solidifies its effectiveness as multi-purpose technology.

Cost-effectiveness of Using a Laser Cutter

For small or large scale operations, laser cutters provide a significant cost advantage. One of the most notable savings comes from energy efficiency when compared to traditional cutting tools. Research indicates modern laser cutting systems use about 50% less energy than conventional methods, wielding great operational savings over time.

In addition, the precise cutting techniques employed by laser cutters also decrease the overall material waste. For example, a laser beam produces a kerf of only 0.1 mm to 0.5 mm wide; thus, achieving material efficiency while also minimizing scrap left over. This precision results in reduced industry costs, particularly in sectors where raw materials like metals and plastics are costly.

In addition, laser cutting systems require less care as opposed to mechanical cutting equipment. Less tool wear and reduced system downtime translates to decreased long-term maintenance spending. A recent study found that, over five years, the maintenance expenses of the laser systems were reported to be 40% lower than those of the traditional mechanical systems.

These analytical findings demonstrate that laser cutters are not only technologically sophisticated, but also strengthen the argument of why businesses looking for leaner operational costs should make the shift.

Reference Sources

1. Perancangan Sistem Multi Computer Numerical Control (CNC) untuk Plotter dan Laser Engraving

- Authors: Diki Muhamad Sobirin, Jana Utama

- Publication Date: 2020-04-03

- Summary: This paper discusses the design of a multi-functional CNC system that integrates both plotter and laser engraving capabilities. The system utilizes USB serial communication between a computer and a microcontroller, with LabVIEW software converting images into G-Code for the CNC machine. The study highlights the ability of the CNC to perform laser engraving on wood, adjusting engraving thickness as needed.

2. Automatic Laser Engraving Machine for Different Materials based on Microcontroller

- Authors: Israa Fayez Yousif et al.

- Publication Date: 2023-05-26

- Summary: This article describes the development of an automatic laser engraving machine that can engrave various materials. The machine uses Inkscape to convert graphics into G-Code, which is then executed by a microcontroller. The study emphasizes the machine’s versatility in industrial applications for engraving and cutting.

3. Optimasi Setup Proses Engraving CNC Laser Cutting Material Akrilik Menggunakan Simplex Centroid Design dan Optimasi Respon

- Authors: Dewa Kusuma Wijaya, Dwi Nurul Izzhati

- Publication Date: 2019-02-01

- Summary: This research focuses on optimizing the setup parameters for a CNC laser cutting machine when working with acrylic materials. The authors used the Simplex Centroid Design method to determine optimal settings for speed, power, and feed interval, measuring responses such as processing time, depth, and roughness.

Frequently Asked Questions (FAQs)

Q: What is the primary difference between CNC engraving and laser engraving?

A: The principal distinction is that CNC engraving employs a mechanical rotary or router machine with an engraving bit which cuts into the material while laser engraving utilizes a laser beam which engraves by vaporizing the material’s surface. This basic difference impacts accuracy, the engravings depth, as well as the range of materials suitable for engraving.

Q: How does a diode laser work in laser engraving?

A: A diode laser for laser engraving works by focusing a beam of light to the surface of the material to be worked on. The optimal material is subjected to a laser beam which heats up the material to ensure vaporization occurs along the intended path of the engraving. Diode lasers are regarded for their accuracy and capability to engrave very detailed patterns.

Q: What are the key differences in materials suitable for CNC vs laser engraving?

A: CNC engraving can be done on a variety of materials such as metal, plastic, and wood because it involves a subtractive process where material is removed by a machine. Laser engraving has the strongest application on materials that vaporize under the intense heat of the laser, such as wood, acrylic, and some metals. Knowing the differences between CNC and laser is important when choosing the engraving method.

Q: What are the advantages of using a CNC machine for engraving vs laser engraving?

A: CNC machines provide deeper cuts and work better on more durable material such as metal; therefore, they are more useful for the removal of large quantities of material and three-dimensional relief works. On the other hand, laser engraving is faster and more precise when engraving softer materials. The choice of engraving type is based on the project’s specifications.

Q: When making the decision of choosing between a CNC or a laser engraving machine, what is the most important factor to consider?

A: The materials that will be engraved, level of precision, and complexity of the project are crucial elements to consider. Each engraving machine comes with its own advantages and disadvantages. For example, CNC machines tend to require some time before they can be skillfully operated yet have unlimited possibilities regarding the range of materials that can be used. With that being said, laser engravers are easier to master, but are limited to intricate details.

Q: How does the steep learning curve of CNC machines compare to laser engravers?

A: Due to the intricate programming and operational controls, CNC machines have a more pronounced learning curve than laser engravers. Users have to grasp machine tools and the subtractive process in which the machine removes material from the workpiece. Conversely, laser engravers are fairly simple to operate and do not require much technical skill, which provides a welcoming environment for novice users.

Q: What are the main uses for CNC and laser engraving machines?

A: CNC engraving machines find a broader range of application in industries and manufacturing for deep, durable engravings, such as intricate designs on metal and woodwork. Commercially, laser engraving machines are more sought after for artistic work like engraving gifts, signs, and other artistic engraving on different materials.

Q: What are the differences in maintenance CNC and laser engraving machines?

A: Yes, there are differences with maintenance. CNC machines typically need greater ex upkeep due to the numerous moving parts, including the rotary and router components which require lubrication and calibration. Conversely, laser engraving machines require less mechanical upkeep but periodic cleaning of the rotary lens and mirrors is needed for peak operational efficiency.

Q: What can help prospective buyers differentiate CNC from laser engraving before making the actual purchase?

A: Prospective buyers should start with understanding the distinct features of CNC and laser engraving by examining the different capabilities each machine possesses, identifying the scope of their specific projects, and determining the type of materials they plan to process. Consulting experts within the field as well as using online platforms to read reviews can serve as sources for determining which type of machine best serves their needs.

Q: What factors should be considered when selecting the right engraving method?

A: Carefully examine the material’s nature, the intricacy of the project, desired detail, production time, and budget. Further, consider the long-term maintenance and operating costs of each machine to make sure that the method is optimal for one’s business or personal use.