Choosing the right cutting method is a critical decision for businesses in manufacturing, construction, and various other industries. CNC cutting and fiber laser cutting are two powerful technologies that dominate the field, each offering unique benefits depending on the project’s specific requirements. But how do you decide which is the better option for your needs? This article breaks down the key differences, advantages, and applications of CNC cutting and fiber laser cutting, helping you make an informed decision. Whether you’re looking for precision, efficiency, or cost-effectiveness, we’ll guide you through the essentials so you can choose the method that best aligns with your objectives.

What is Laser Cutting and How Does it Work?

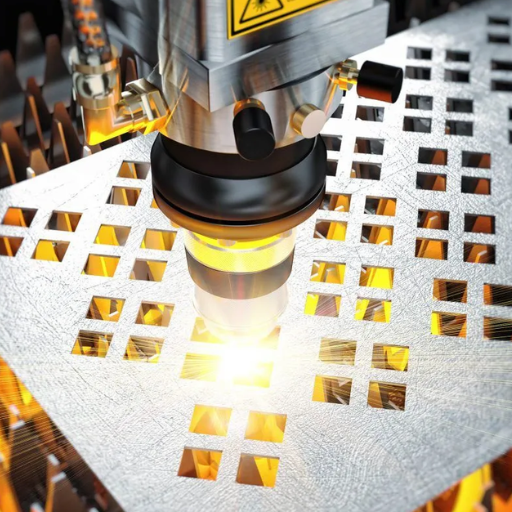

Laser cutting is a precise and efficient method of cutting materials using a focused beam of light. The laser beam is generated through a process of stimulating atoms to emit light in a concentrated form. This beam is directed onto the material, where it melts, burns, or vaporizes the surface, creating clean and accurate cuts. The process is controlled by CNC (Computer Numerical Control) systems, ensuring high precision and repeatability. Laser cutting is commonly used in industries like manufacturing, automotive, and aerospace due to its ability to handle complex designs and various materials, including metals, plastics, and wood.

Understanding the Laser Cutting Process

Modern laser cutting technology has significantly evolved, incorporating advanced features that enhance efficiency, accuracy, and versatility. Fiber lasers, a cutting-edge innovation, are now widely used due to their exceptional precision and energy efficiency compared to traditional CO2 lasers. Fiber lasers can deliver up to 30% energy efficiency, a substantial increase from the typical 10-15% offered by CO2 systems. This efficiency makes them ideal for cutting thinner materials such as steel, aluminum, and copper, contributing to reduced operational costs and lower environmental impact.

One of the defining aspects of contemporary laser cutting systems is their ability to process intricate designs at astonishing speeds. High-quality machines can achieve cutting speeds of up to 1,000 inches per minute (IPM), depending on material thickness and type. This capability is further enhanced by CNC systems, which ensure precise handling of complex geometries while minimizing waste.

Additionally, modern laser cutting machines support a wide range of materials with thicknesses from 0.5 mm to over 25 mm, depending on the laser’s power output. For instance, a 10 kW fiber laser is capable of cutting stainless steel up to 40 mm thick, demonstrating its versatility across industries. These innovations continue to make laser cutting an indispensable tool in manufacturing, capable of meeting the stringent demands of modern production.

Key Components of a Laser Cutting Machine

A laser cutting machine is comprised of several critical components that work together to ensure precision and efficiency. Below is a detailed breakdown of these components:

- Laser Resonator

The laser resonator is the core of any laser cutting system, responsible for generating the laser beam. It does this by amplifying light through optical gain media such as CO2 gas, fiber, or crystal. Modern fiber lasers, for instance, are highly energy-efficient and capable of producing beams with wavelengths as small as 1 micron, making them ideal for intricate and high-precision cuts.

- Beam Delivery System

After the laser is generated, it is directed to the workpiece via a beam delivery system. This system includes mirrors for CO2 lasers or flexible fiber-optic cables in fiber laser machines. The beam delivery system ensures that the beam remains consistent and focused throughout the process.

- Cutting Head

The cutting head is equipped with a focusing lens or, in some cases, a parabolic mirror that concentrates the laser beam into a fine spot. This allows for precision cutting and enables the machine to handle complex contours. Air or gas assists, such as oxygen or nitrogen, are often integrated into the cutting head to remove molten material and ensure clean edges.

- Worktable

The worktable or cutting bed is where the material is placed during the cutting process. Typically, these tables are honeycomb or slatted to minimize contact points with the material and prevent heat accumulation. Many machines include an automated material handling system to streamline operations and improve productivity.

- Control System

The control system acts as the brain of the machine, coordinating the laser beam, movement, and auxiliary systems such as cooling and ventilation. Advanced control systems often include CNC (computer numerical control) capabilities, enabling intricate designs by interpreting CAD files with precision.

- Cooling Unit

Lasers generate significant amounts of heat during operation, necessitating a cooling unit to maintain system stability. Many machines integrate water chiller systems which ensure that both the laser resonator and optics remain at an optimal operating temperature.

- Exhaust System

An exhaust system is vital for removing smoke, fumes, or debris produced during the cutting process. Proper ventilation not only increases the lifespan of the equipment but also ensures a safer environment for operators.

- Power Supply Unit

To power the laser and all associated components, a stable and efficient power supply is required. High-power lasers, particularly those used in industrial applications, demand robust and reliable sources of energy.

By working in harmony, these components enable laser cutting machines to achieve unmatched precision, speed, and versatility, catering to applications ranging from aerospace to automotive manufacturing. The integration of advanced technologies has further pushed the boundaries, allowing these machines to handle everything from delicate etching to cutting through ultra-thick materials with ease.

The Role of Laser Beam in Cutting

The laser beam serves as the core element in laser cutting, driving the precision and accuracy of the process. Generated through stimulated emission of radiation, the beam is focused into an intense, high-energy spot, which is capable of melting, burning, or vaporizing a variety of materials. Modern advancements in laser technology have significantly enhanced beam quality and power density, enabling exceptional cutting performance across different materials like metals, plastics, and composites.

For instance, fiber lasers are now widely recognized for their superior efficiency and high-power outputs, making them ideal for cutting reflective materials such as aluminum and brass. With power levels reaching up to 30 kW in industrial setups, they can cut steel sheets up to 25 mm thick at remarkable speeds without compromising on precision. Additionally, CO2 lasers, although less common in recent years, continue to be valuable in cutting non-metallic materials such as wood and acrylic due to their longer wavelengths.

Accurate and consistent laser cutting is further achieved through beam shaping and focusing techniques, which ensure that the energy is confined precisely to the target area. Reports show that with the use of advanced beam controlling technologies, cutting efficiency has improved by over 20%, while minimizing material waste. This makes laser beams an indispensable tool in industries like aerospace, automotive, and electronics, where precision and quality are paramount.

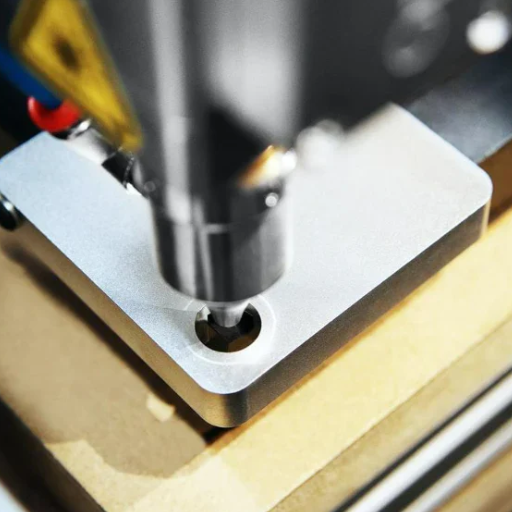

How Does CNC Cutting Differ from Laser Cutting?

CNC cutting and laser cutting differ primarily in their method and precision. CNC cutting relies on physical contact between a cutting tool and the material, with the tool being guided by computer programming to carve, drill, or mill the desired shape. It is highly effective for thicker materials and offers versatility with various materials such as metals, wood, and plastics. On the other hand, laser cutting uses a concentrated laser beam to slice through materials without physical contact, delivering exceptional precision and clean edges. Laser cutting is ideal for intricate designs and thinner materials, making it suitable for applications requiring high accuracy. Additionally, laser cutting typically produces less material waste compared to CNC cutting.

Comparing CNC Cutting and Laser Cutting Technologies

As you evaluate the technologies of CNC cutting and laser cutting, it is clear that each method possesses unique strengths designed to meet specific requirements. CNC cutting is unparalleled when it comes to versatility and strength, as it is able to work on a variety of materials ranging from softer substrates like wood to tougher ones like metals, hardwoods, and even thick ones. This is made possible by the mechanical cutting system that uses tools like drills and mills to cut through the material. For example, CNC machining can cut slots into parts 10 inches thick or more, depending on the material and tool used. It is therefore very useful in the aerospace, construction, and heavy manufacturing industries.

On the other hand, laser cutting provides incomparable speed and accuracy for delicate and intricate designs. Typically, laser beams are 0.1 mm wide, providing unparalleled precision for small or intricate designs. In addition, laser cutting can process materials with thicknesses of about 1 inch for metals like steel and aluminum, and a bit less for stainless steel. More recently, fiber lasers have been developed, and their main advantages are faster cutting and greater energy efficiency, with some industrial-grade machines slashing power use by 50%. Because of these attributes, laser cutting is widely used in the electronics, jewelry, and automotive industries where intricacy and precision are paramount.

Another major comparison focuses on productivity as well as resource waste. CNC cutting machines are multifunctional; however, they may result in excess material waste because of their physical tooling and clearance requirements. In contrast, laser cutting reduces material waste because it does not require any physical contact, making the most of raw materials. For instance, laser-cut parts tend to have smoother edges, which eliminates the need for additional work in post-production and reduces time spent.

Cost factors are paramount, as with everything else. Simpler designs and rougher materials tend to require less expensive setup costs on CNC machines when compared to laser cutting. On the other hand, laser cutting may involve a higher cost for setting up the necessary equipment, but its operational cost on repetitive jobs as well as more complex designs is much lower. The CNC machines are much more efficient when they are used for producing larger quantities of the same piece. The repetitive nature of laser cutting also makes it ideal for bulk production, but not as much compared to laser cutting. The right option is mostly determined by the material type, complexity of the design, how much pieces need to be produced, and what the budget is for that specific application. Efficiency and the required outcomes can be maximized by manufacturers when they utilize the advantages each method offers.

Differences in Precision and Cutting Speed

When evaluating precision and cutting speed between traditional cutting methods and laser cutting, notable contrasts emerge. Laser cutting is renowned for its high precision, often achieving tolerances as tight as ±0.001 inches, making it ideal for intricate and detailed designs. This level of accuracy is particularly advantageous for industries requiring complex shapes, such as aerospace and electronics. Conversely, traditional cutting methods, such as mechanical cutting, generally offer tolerances closer to ±0.01 inches, which may suffice for less demanding applications.

Speed is another decisive factor. Laser cutting excels in processing thin materials quickly, with speeds reaching up to 20 meters per minute depending on the material and laser power. This efficiency can significantly cut down production times for high-volume projects. On the other hand, traditional methods may lag in speed, especially for dense or harder materials, as they rely on physical force and tools that require frequent maintenance and replacements.

Furthermore, laser cutting reduces the need for post-processing due to its clean edges, while traditional methods may necessitate additional finishing to smooth out rough surfaces or burrs. By understanding these differences, manufacturers can make informed decisions tailored to their specific production needs, ensuring both quality and efficiency.

Applications: CNC Cutting vs Laser Cutting

Both CNC cutting and laser cutting have revolutionized manufacturing by offering precise, versatile, and efficient solutions for a wide range of industries. Each method finds optimal applications depending on the material, required accuracy, and production needs.

CNC Cutting Applications

CNC (Computer Numerical Control) cutting is ideal for projects that handle robust and thick materials, such as wood, metal, and plastics. Industries like automotive, aerospace, and furniture manufacturing often rely on CNC cutting to create intricate parts with mechanical strength. For instance, CNC cutting is widely used in producing gears, engine components, and detailed wooden furniture. One key advantage is the compatibility of CNC machines with a variety of tooling options, which enable operations like drilling, milling, and turning. This adaptability makes CNC cutting a go-to solution for creating complex 3D products and prototypes.

Laser Cutting Applications

Laser cutting, on the other hand, excels in industries that require high precision and aesthetically appealing finishes. It is especially prevalent in the electronics, jewelry, and fashion industries due to its ability to produce clean and intricate designs. For example, laser cutters are frequently used to manufacture custom circuit boards, engrave delicate patterns on jewelry, and create intricate fabric or leather designs in fashion. Additionally, laser cutting is indispensable for thin and delicate materials like paper, acrylic, and stainless steel sheets. With tight tolerances often within ±0.01mm, laser cutting is an essential tool for ensuring exactness in high-tech manufacturing processes, such as medical device and aerospace applications.

By leveraging the strengths of both technologies, industries can optimize their production processes and achieve superior results. Selecting the right method ultimately depends on the project’s specific requirements, ensuring both quality craftsmanship and operational efficiency.

Exploring the Advantages of Laser Cutting

Laser cutting offers several key advantages, making it a versatile and effective tool in modern manufacturing. It provides exceptional precision, allowing for intricate designs with minimal material waste. The process is highly efficient, offering faster cutting speeds compared to traditional methods. Additionally, laser cutting supports a wide range of materials, including metals, plastics, and composites, enabling flexibility across industries. Its non-contact nature reduces the risk of material deformation, ensuring consistent quality. These benefits make laser cutting an ideal choice for projects requiring accuracy, speed, and versatility.

Benefits of Using Laser Cutter for Metal Fabrication

- High Precision and Accuracy

Laser cutting technology offers exceptionally high precision, with tolerances as low as ±0.001 inches. This ensures intricate designs and highly detailed patterns can be achieved without errors, making it ideal for industries like aerospace and automotive where precision is critical.

- Versatility in Metal Types

Laser cutters can work with a wide variety of metals, including steel, aluminum, brass, titanium, and even alloys. This versatility means manufacturers can handle diverse projects without needing multiple machines or methods.

- Efficient Material Utilization

The narrow cutting kerf of laser cutters minimizes material wastage. Compared to traditional methods, this efficiency can reduce material costs by up to 20-30%, depending on the complexity of the project.

- Faster Processing Speeds

Laser cutting systems operate at impressive speeds, processing thin sheets of metal at rates up to 20 m/min. This rapid performance can significantly reduce project timelines, especially for large-scale production.

- Cost-Effective for Complex Designs

Traditional cutting methods may require custom tools for complex designs, increasing production costs. Laser cutters eliminate this need, as they rely on CAD models to guide the process, reducing tooling expenses by as much as 50%.

- Minimal Maintenance and Downtime

Advanced laser cutters require minimal maintenance due to their durable components and automated systems. This reliability ensures less downtime, enhancing overall productivity in metal fabrication workflows.

- Improved Edge Quality

Laser cutters produce smooth, burr-free edges, often eliminating the need for post-processing. This not only saves time but also ensures a professional finish suitable for end-use applications.

- Energy-Efficient Operation

Modern laser cutting systems are highly energy-efficient, consuming 40% less energy than older methods like plasma cutting. This contributes to lower operational costs and a smaller environmental footprint.

- Scalability for Mass Production

Automated laser cutting machines are designed for scalability, making them ideal for both small batch production and high-volume manufacturing. Their speed and precision remain consistent regardless of output size.

- Safe and Eco-Friendly

Since laser cutters are non-contact tools, they reduce the risk of workplace injuries caused by traditional mechanical tools. Additionally, the use of advanced fume extraction systems minimizes harmful emissions, making the process environmentally friendly.

These advantages make laser cutting an indispensable technology for modern metal fabrication, driving innovation and efficiency across numerous industries.

Why Choose Fiber Laser Cutting?

Fiber laser cutting has rapidly become the preferred choice in the manufacturing and fabrication industries due to its unparalleled precision, efficiency, and cost-effectiveness. Its ability to handle a wide range of materials, including stainless steel, aluminum, brass, and copper, makes it a versatile solution for diverse applications. Here are some key reasons why fiber laser cutting stands out:

- Exceptional Precision and Speed

Fiber laser machines can achieve cutting speeds up to 3 times faster than CO₂ laser systems when working with thin metals. With the ability to produce intricate and highly detailed cuts, the technology ensures minimal material waste and clean edges, reducing the need for additional finishing processes. For instance, thin stainless steel sheets can be cut at speeds exceeding 20 meters per minute, optimizing production timelines.

- Energy Efficiency

Unlike CO₂ lasers, fiber laser systems are highly energy-efficient, consuming up to 50% less power during operation. This not only reduces operating costs but also aligns with sustainability goals by lowering the overall environmental impact of manufacturing processes.

- Minimal Maintenance Requirements

Fiber lasers have fewer moving parts and a simplified design compared to traditional cutting systems, leading to reduced maintenance needs and longer operational lifespans. The lifespan of a fiber laser source can exceed 100,000 working hours, ensuring consistent performance over years of use.

- Ability to Cut Reflective Materials

One of the unique advantages of fiber laser cutting is its capability to process highly reflective metals, such as aluminum and copper, with ease. This is due to the shorter wavelength of the laser, which minimizes refraction and improves material absorption rates.

- Reduced Operating Costs

Despite the initial investment, fiber laser cutting systems have lower operating costs in the long term. Energy savings, minimized maintenance, and faster production cycles contribute to substantial cost reductions for businesses.

- Automation Compatibility

Modern fiber laser machines are often equipped with advanced automation technologies, including CNC programming and robotic loading/unloading systems, which further improve operational efficiency and reduce manual labor requirements.

These advantages make fiber laser cutting a game-changing technology, meeting the demands of today’s fast-paced and competitive industries. Whether it’s aerospace, automotive, or custom metal art, fiber laser cutting provides a reliable and future-ready solution for precision manufacturing.

High Precision and Faster Cutting Speeds

Fiber laser cutting is renowned for delivering exceptional precision, with cutting tolerances often reaching as tight as ±0.001 inches in industrial applications. This unmatched accuracy is achieved through the use of highly focused laser beams that create a narrow heat-affected zone, minimizing material distortion and ensuring clean edges. Additionally, the integration of advanced motion systems and automated controls enables consistent performance across complex geometries.

When it comes to cutting speeds, fiber lasers outperform many traditional cutting methods. For instance, a 3kW fiber laser can cut through 1mm thick stainless steel at speeds exceeding 30 meters per minute. This is significantly faster compared to CO2 lasers or plasma cutting systems, which often require more time for similar tasks. The higher cutting speeds help industries meet tight production deadlines without sacrificing quality.

Furthermore, fiber laser cutting supports a wide range of materials, from thin-gauge metals to reflective materials like aluminum and brass, making it a versatile solution for diverse manufacturing requirements. This versatility, combined with superior precision and speed, positions fiber laser cutting as an indispensable asset in modern industry.

What are the Types of Laser Cutting Machines?

There are three main types of laser cutting machines:

- Fiber Laser Cutting Machines

These are highly efficient and versatile, suitable for cutting a variety of materials such as steel, aluminum, and brass. They are known for their precision, speed, and low maintenance requirements.

- CO2 Laser Cutting Machines

CO2 lasers are ideal for cutting non-metallic materials like wood, glass, and acrylic. They are widely used in applications requiring smooth edges and intricate designs.

- Crystal Laser Cutting Machines

These machines use crystals such as Nd:YAG or Nd:YVO4. They are particularly effective for high-powered cutting of thick or hard materials and are commonly employed in specialized industrial applications.

Understanding Fiber and CO2 Laser Systems

When comparing fiber and CO2 laser systems, I find that each has its strengths depending on the application. Fiber lasers excel in cutting and engraving metals due to their precision, speed, and low maintenance requirements. On the other hand, CO2 lasers are better suited for non-metals like wood, glass, and acrylic, delivering smooth edges and excellent quality for intricate designs. I would choose the system based on the material and specific needs of the project.

Choosing the Right Cutting Technology for Your Needs

Choosing appropriate cutting technology requires considering factors like material compatibility, precision, efficiency, and cost. For example, fiber laser systems are very effective when cutting reflective metals such as aluminum, brass and copper. They outperform other methods in terms of speed as well. Industry analyses suggest that fiber laser systems outperform CO2 lasers by upto three times for thin sheet metal fibers. This makes them a popular option in industries that value speed and energy efficiency.

Meanwhile, CO2 lasers still dominate other applications involving non-metal materials such as wood, plastic, textile, and glass. Their edge quality consistently exceeds standards, and they can accommodate a greater range of thicknesses, which is beneficial for multi-layered designs. In addition, CO2 systems have also become more energy-efficient over time making operational cost lower.

Mixed material projects become simpler with hybrid laser systems, as they are a great option to consider. These systems integrate the benefits of fiber and CO2 lasers which allow for seamless transitions between cutting metals and non-metals without shedding quality or productivity. Analyzing the materials you work with and the scale of the production allows you to choose cutting technology that maximizes efficiency alongside consistency in results.

Pros and Cons of Plasma Cutting vs Laser Cutting

Plasma Cutting

Pros

- Versatility: Can cut through a wide range of electrically conductive materials, including stainless steel, aluminum, and thick carbon steel.

- High Cutting Speed: Excels in cutting thicker materials, typically above 1/4 inch, with faster speeds compared to most laser cutters.

- Cost-Effectiveness: Generally more affordable than laser cutters, both in terms of initial investment and maintenance costs.

- Tolerant to Material Types: Performs well even on painted, rusted, or rough surfaces.

- Robust Performance: Handles high-volume industrial applications efficiently.

Cons

- Limited Precision: Produces a rougher edge quality compared to laser cutting, requiring additional finishing for high-precision applications.

- Kerf Width: Larger kerf width due to the nature of the plasma arc, reducing the detail achievable on finer cuts.

- Heat-Affected Zone: Generates more heat, which can cause warping or distortions in thinner materials.

- Limited Thin Material Capability: Less effective for cutting extremely thin materials.

- No Clean Cutting for Non-Metals: Cannot handle non-conductive materials such as plastics or wood.

Laser Cutting

Pros

- Exceptional Precision: Achieves high accuracy with minimal kerf width, making it ideal for intricate designs and detailed cuts.

- Smooth Edge Quality: Produces clean and nearly burr-free edges, reducing the need for post-processing.

- Material Flexibility: Suitable for metals, non-metals (e.g., wood, acrylic, and plastics), and thin materials.

- Energy Efficiency: Uses less power compared to plasma cutters for certain applications.

- Automation-Friendly: Integrates well into CNC systems, enhancing workflow automation and repeatability.

Cons

- Higher Initial Cost: Requires a larger investment upfront, and maintenance costs, such as lens and mirror replacements, can add up over time.

- Slower on Thick Metals: Cutting speeds decrease significantly on materials thicker than 1/4 inch, limiting efficiency on heavy-duty applications.

- Limited Heat Tolerance: Struggles with extremely reflective materials like copper and brass unless specialized systems are used.

- Steeper Learning Curve: Requires expertise to set up and optimize for different materials and thicknesses.

- Vulnerability to Surface Conditions: Performs best on clean surfaces; rusted or painted metals can pose challenges.

By weighing the pros and cons of plasma cutting versus laser cutting, businesses and individuals can better align their choice with their specific operational demands, budget considerations, and desired outcomes.

Which is Better for Metal Cutting: CNC or Fiber Laser Cutting?

When deciding between CNC cutting and fiber laser cutting for metal, the choice primarily depends on the specific needs of the project. Fiber laser cutting excels at precision and speed, making it ideal for intricate designs and high-volume production. It also handles thinner materials more efficiently, with minimal waste. On the other hand, CNC cutting is better suited for thicker materials and offers versatility for a wider range of projects, including non-metal materials. For high-accuracy requirements and a clean finish, fiber laser cutting is often the superior choice, while CNC cutting works best for heavy-duty tasks and mixed-material cutting.

Assessing Cutting Thicker Materials with Fiber Laser

Fiber laser technology has become a prominent choice for cutting thicker materials due to its precision, efficiency, and adaptability. It delivers a highly concentrated beam of light energy, which can achieve cutting depths of up to 30 mm for certain metals like steel and aluminum, depending on the laser’s power output. Modern fiber lasers, often rated between 3 to 15 kW, optimize metal cutting across varying thicknesses while maintaining remarkable edge quality—reducing the need for post-processing efforts significantly.

Advancements in beam shaping and focusing capabilities enhance the cutting performance on dense materials, allowing for clean and efficient sections, even in complex geometries. Additionally, fiber laser cutting systems operate faster than traditional methods, with cutting speeds for 10 mm mild steel reaching up to 3 m/min, depending on factors like material type and assist gas used. The integration of automated controls also minimizes human error, ensuring consistent accuracy.

A critical benefit of fiber lasers is their lower operational cost over time. With higher energy efficiency—converting up to 40% of electrical input into usable light— and minimal maintenance requirements compared to CO2 lasers, businesses can significantly reduce production expenses on heavy-duty projects.

While fiber laser systems are typically an upfront investment, their ability to handle a wide scope of materials and thicknesses with speed and precision makes them a highly valuable solution for industries such as aerospace, automotive, and heavy machinery manufacturing that demand precise cutting of thick, durable materials.

The Efficiency of Fiber Laser Cutting Machine for Metal

Fiber laser cutting machines have revolutionized metal cutting processes with their unmatched efficiency, precision, and versatility. These machines operate using highly focused laser beams, enabling precise cuts even on the most challenging materials, such as stainless steel, aluminum, and copper. One of their standout features is their extraordinary cutting speed. For instance, a standard 2kW fiber laser can cut through stainless steel sheets of up to 6mm at approximately 14 meters per minute, significantly outperforming older technologies like CO2 lasers.

Additionally, fiber lasers boast an energy efficiency rate that is 30% higher than competing systems, making them an eco-friendly option for modern industries striving to reduce carbon footprints and energy expenses. They also require less maintenance due to their solid-state design, translating to reduced downtime and lower operating costs. Industries such as manufacturing and industrial engineering benefit from their ability to handle diverse thicknesses of metals with unparalleled accuracy, allowing for the production of intricate, high-quality designs.

The integration of advanced automation features further enhances their efficiency. Many modern fiber laser systems include smart sensors and IoT-enabled controls, optimizing cutting processes in real time and ensuring consistent results with minimal human intervention. These breakthroughs solidify fiber laser cutting machines as the go-to solution for businesses demanding rapid, reliable, and cost-effective metal fabrication.

Cost Implications: CNC Machine vs Fiber Laser

When analyzing the cost implications of CNC machines and fiber laser cutting systems, it is essential to consider factors such as initial investment, operational expenses, and long-term value. CNC machines typically have a lower upfront cost compared to fiber laser systems, making them a more accessible option for smaller businesses or those with limited capital. Entry-level CNC machines can start at approximately $10,000 to $25,000, whereas fiber laser systems usually range from $50,000 to over $200,000, depending on power and functionality.

However, the operational costs paint a different picture. Fiber laser systems, while more expensive initially, often demand lower maintenance and energy costs due to their high efficiency and minimal reliance on consumables like cutting tools or lubrication. For instance, fiber lasers are known for their long-lasting diodes and reduced downtime for maintenance, providing substantial long-term savings. CNC machines, on the other hand, require routine tool replacements, calibration, and potentially higher electricity consumption, especially for larger or more complicated operations.

The productivity of fiber lasers further offsets their higher upfront costs. With cutting speeds significantly surpassing those of CNC machines, particularly when working with thin materials, fiber lasers enable businesses to streamline production cycles and increase output. This efficiency can lead to faster project completion and higher profitability over time, making them a worthwhile investment for high-demand manufacturing environments.

Ultimately, the choice between CNC machines and fiber laser systems depends on the specific needs and scale of the business. For operations focused on detailed machining or working with materials unsuitable for laser cutting, CNC machines remain a solid choice. However, for industries prioritizing speed, precision, and long-term cost-effectiveness, fiber laser systems emerge as the superior option.

Reference Sources

-

Laser Cutting Technique: A Literature Review (2022)1:

- Focus: This study reviews the parameters influencing laser cutting, such as laser power, cutting speed, and gas pressure, across various materials like metals and plastics.

- Key Findings: Fiber lasers offer superior precision and reduced heat-affected zones compared to traditional methods. Optimization of parameters like scanning speed and gas pressure is critical for maximizing efficiency and minimizing defects.

- Methodology: The study evaluates experimental and theoretical research, emphasizing the use of finite element analysis (FEA) and software tools for process optimization.

-

A Technical and Commercial Comparison of Fiber Laser and CO2 Laser Cutting (2012)2:

- Focus: This paper compares fiber and CO2 lasers in terms of cost, cutting speed, and quality.

- Key Findings: Fiber lasers are ideal for thin sheet metals and high-volume production, while CO2 lasers are more versatile for diverse applications. Fiber lasers excel in speed and maintenance efficiency.

- Methodology: A comparative analysis based on industrial applications and operational parameters.

-

Direct Diode Lasers for Industrial Laser Cutting (2014)3:

- Focus: Examines the performance of direct diode lasers (DDL) against fiber and CO2 lasers.

- Key Findings: While DDLs show potential for cost reduction, fiber lasers outperform in beam quality and cutting speed for industrial applications.

- Methodology: Experimental tests on steel and aluminum using a design of experiments approach.

- Top CNC Fiber Laser Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the main differences between CNC cutting and fiber laser cutting?

A: CNC cutting generally involves traditional methods like milling or routing, using a physical cutting tool, while fiber laser cutting utilizes a high-powered laser beam to melt or vaporize material. CNC machines are typically used for drilling, routing, and milling, whereas fiber laser cutters are often used for cutting thin metals and other materials with precision.

Q: When should I choose a fiber laser system over a CNC router?

A: A fiber laser system is a better choice for rapid cutting of thin metals and for achieving intricate designs with high precision. If you need to cut a wide range of materials with complex shapes, using a laser cutting method can provide more benefits of laser cutting, such as cleaner edges and faster processing times.

Q: What are the benefits of laser cutting compared to traditional CNC cutting methods?

A: The benefits of laser cutting include high precision, reduced material waste, and the ability to cut complex shapes without changing tools. Laser cutting produces clean edges and can cut various materials quickly, especially when cutting thin materials. It also reduces the risk of material deformation since it is a non-contact process.

Q: How does a CNC laser differ from a fiber laser cutter?

A: A CNC laser refers to any laser integrated with CNC technology for automated control. A fiber laser cutter, on the other hand, specifically uses a fiber optic cable to deliver the laser beam, which is particularly effective for metal cutting. Fiber lasers are more efficient and require less maintenance compared to traditional CO2 lasers.

Q: Can a milling machine be replaced by laser cutting technology?

A: While laser cutting and CNC milling serve different purposes, laser technology can replace milling for certain applications, especially for cutting thin materials and creating intricate designs. However, CNC milling is still necessary for processes that require physical contact to shape materials, such as cutting thicker metals.

Q: What types of materials are commonly used for cutting with fiber laser systems?

A: Fiber laser systems are commonly used for cutting metals such as stainless steel, aluminum, and copper. They can also cut non-metal materials like plastics and composites, offering versatility in cutting a wide range of materials with precision and speed.

Q: How does the cutting method in laser and CNC differ in terms of precision and speed?

A: Laser cutting typically provides higher precision and speed compared to traditional CNC cutting methods. The high-powered laser beam allows for rapid cutting with minimal material waste and produces clean, precise edges. CNC cutting methods might require multiple passes and tool changes, whereas laser cutting can often complete tasks in one pass.

Q: Are co2 and fiber lasers interchangeable for any cutting task?

A: No, CO2 and fiber lasers serve different purposes. CO2 lasers are better suited for cutting non-metal materials like wood, acrylic, and glass, while fiber lasers excel in cutting metals. Choosing between CO2 and fiber lasers depends on the material being used and the specific requirements of the cutting task.

Q: What role does a cnc cutting machine play in the manufacturing industry?

A: A CNC cutting machine is integral to manufacturing, providing automated, precise cutting for various materials. It is widely used for producing components in industries such as automotive, aerospace, and construction. CNC machines offer consistency, efficiency, and the ability to handle complex designs, often in conjunction with laser solutions for enhanced capabilities.