The advent of CNC laser cutting has transformed laser cutting industries approach towards modern manufacturing, allowing for complex shapes to be constructed with Relentless precision. Regardless if you are new in the field or an experienced specialist looking to expand your horizons, embracing new designs and modernization in manufacturing processes is all made possible by grasping the technology’s features. This guide serves as a one-stop resource for everything related to CNC laser cutting, from basic principles to advanced advice and tricks. You will learn in detail the workings of CNC laser cutters with respect to different processes CNC laser cutters perform and how to optimally use them to enhance your work. Prepare yourself to learn the intricate details and the fundamentals of CNC lasers.

What is a CNC Laser and How Does it Work?

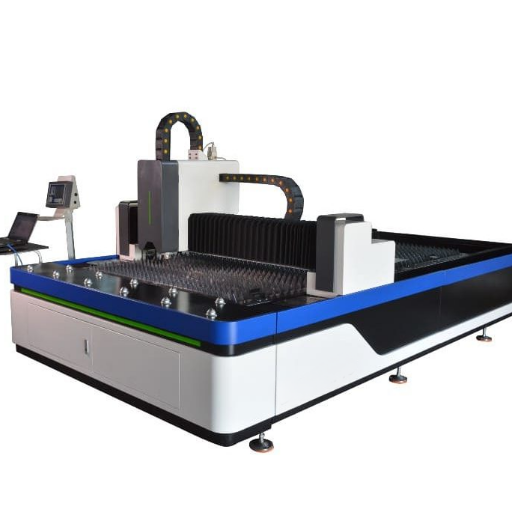

A CNC laser machine is an example of a computer-controlled mechanical device that can cut, engrave and mark materials with great precision. It can cut through materials by focusing a laser light beam on the surface of the material. The energy from the laser light serves to either vaporize or burn the material to create specific designs. The use of a CNC system ensures accuracy since it operates and executes a design that has been drawn previously. This method is used extensively in automotive, manufacturing and design industries.

Understanding CNC Technology

The efficiency brought about by CNC (Computer Numerical Control) technology is transforming manufacturing industries. This technology works by embedding software-controlled commands that serve to control the machines and tools to work on components and products with high precision. The CNC machine market is estimated to reach $102.22 billion in 2030 at a CAGR of 7.3% from 2023, fueled by the aerospace, automotive, healthcare, and electronics industries.

Ensuring consistent quality in mass production enables the maintaining of accuracy for parts as small as 0.001 inches. In addition, CNC systems are becoming smarter and more versatile with the advent of AI, IoT, and cloud computing, leading to optimization of workflows and reduction of downtimes. For instance, modern CNC systems are integrating features such as monitoring of real-time machine cybernetics for predictive maintenance which assist in avoiding expensive interrupt repairs.

From laser cutters and 5 axis mills to 3D printers, CNC technology remains a commanding force behind the efficiency and advancement of industrial processes.

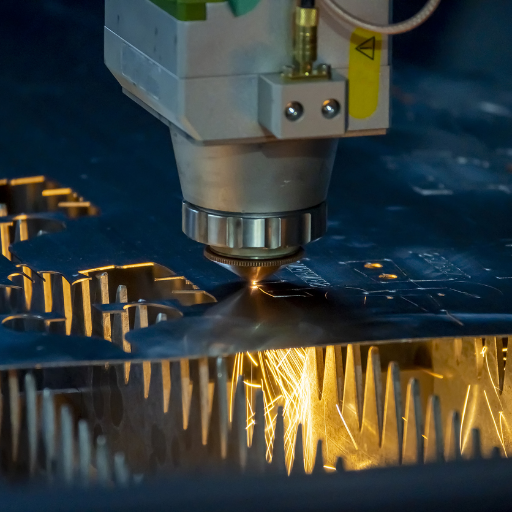

The Role of the Laser Beam in Cutting

A modern marvel in manufacturing laser cutting technology is a form of processing laser beams and uses a powerful, focused stream of light to cut, engrave or shape materials. The global market equips industrial laser systems in automotive, aerospace, and electronics with a powerful laser beam enabling mastering precision tools resulting in high demand_predictions in the growth of laser cutting estimation reach a 9.3% rise till 2030.

With minimal waste and a smooth edge finish, laser cutting can now slice through wood, glass, plastics and even metals. What’s more, modern laser cutting machines now come equipped with new-age technologies such as optimization based AI algorithms and IoT enabling them to monitor and control in real time, on the fly, as well as predict maintenance needs. According to industry reports, this boosts efficiency by 35%!

Furthermore, like most other technologies, laser cutting is becoming greener with advancements in fiber lasers and new-age energy efficient models which vastly improved old CO2 lasers. As a result, energy consumption dropped by a stunning 60%. This makes laser cutting fiber far more appealing to manufacturers working towards eco-friendly sustainability goals. Regardless, it is increasingly evident that as technology continues to evolve, laser cutting will redefine precision manufacturing with its incredible adaptability while maintaining top-notch quality and speed.

Different Types of CNC Laser Machines

There are several types of CNC laser machines, including CO2 lasers, fiber lasers, diode lasers, and crystal lasers, each designed for specific applications and materials.

| Type | Energy | Usage | Materials | Efficiency |

|---|---|---|---|---|

| CO2 Laser | High | Cutting/Etching | Non-metals | Moderate |

| Fiber Laser | Very High | Engraving/Marking | Metals/Non-metals | High |

| Diode Laser | Low | Small-Scale Tasks | Plastics/Wood | Low |

| Crystal Laser | Moderate | Precision Cutting | Metals | Moderate |

How to Choose the Right CNC Laser Cutter?

- Material Type: Choosing a laser cutter requires a consideration of the materials you will be using. For example, fiber lasers suit metals while CO2 lasers are more appropriate for non-metals.

- Desired Power Level: The power of the laser should be set according to its application. Cutting thick materials needs high-power lasers, while low-power lasers are sufficient for small-scale tasks and engraving.

- Application: Establish the main function like cutting, engraving, or marking. Every kind of laser has its area of specialization.

- Budget: Settle on a financial plan considering the initial investment, maintenance, and energy consumption. While fiber lasers have operating benefits, they tend to be more expensive than other options.

- Efficiency and Longevity: Choose a model with operational efficiency and high durability which leads to reduced long-term costs. Less expensive models may have limited durability and reliability.

Assessment of Laser Power and its Compatibility

Understanding the purpose and scope of work is essential when selecting a CNC laser machine, as is knowing the laser power specification and its compatibility with the chosen material. Like most types of industrial machines, laser cutters offer different power configurations, with each one rated in watts. Based on the laser power, systems may be categorized into low power and high power. Low power laser systems, 40W to 80W, are best suited for non-metallic wood, acrylic, and plastic cutting and engraving. Different types of metals also have different power requirements. High power lasers start from 100W to over 1000W for cutting stainless steel, aluminum, and other thicker or more resistant metals.

Using lasers to cut materials hinges on their power levels. A 500W laser machine can cut mild steel up to 6 mm in thickness, while a 1000W machine can handle 12mm, all depending on the material and its quality. Because laser precision and speed are important, they also depend on the configuration of the machine and power of the source. Most modern machines employ advanced CO2 or fiber laser technology, with fiber lasers offering faster and more efficient processing. CO2 lasers require more maintenance than fiber lasers, and result in slower fabricating speeds than fiber lasers.

Furthermore, while assessing compatibility, it is important to note the software component of the machine and whether it aligns with mainstream design programs like AutoCAD or Adobe Illustrator. Constructive Systems often provide automation technology that streamlines productivity, enhances real-time diagnostics, and material usage. Users can expect consistent and precise results in multiple applications if a technologically advanced system is coupled with sufficient laser power.

Comparing CO2, Diode, and Fiber Lasers

Analyzing CO2, diode, and fiber lasers reveals each one has unique distinctive advantages tailored to different applications.

- CO2 Lasers: Used primarily for engraving and marking nonmetals like plastics, wood and glass. They are very effective in applications needing precision with organic materials.

- Diode Laser: Used for simple engraving or marking tasks which require low power. Their small size and low cost make them popular for small projects.

- Fiber Lasers: Designed for heavy duty and industrial applications requiring high precision work on metals and reflective materials. These lasers outshine their competitors due to high durability and fast processing speeds.

Make sure to consider the project’s materials, precision needs, and scale to select best suited laser for your particular requirements.

What Materials Can Be Cut with a CNC Laser?

- Examples of metals are steel, aluminum, and brass.

- Different types of wood include plywood, MDF, and hardwoods.

- Plastics are also applied as acrylic as well as polycarbonate.

- Fabric and leather can be categorized as soft materials.

- Glass can be used for engraving or making thin cuts.

Advantages of CNC Laser Cut Aluminum and Brass Metals

Aluminum and brass metals are best cut with CNC laser machines because of their speed and accuracy. The modern CNC laser machines work with either CO2 or fiber laser, and both have the ability to cut metals ranging from 0.5 mm to 25 mm thick steel.

Fiber lasers are very useful for cutting aluminum and brass metals because of their weaker wavelengths. For instance, a 2000W fiber laser can cut aluminum up to 12 mm thick at a staggering 1 to 8 meters per minute, depending on the complexity and finish required.

Moreover, automated CNC systems further improve accuracy, enhance wastage and allow complex designs to be copied repeatedly. Moreover, high precision parts can be manufactured as close as ±0.1 mm accurate, making them perfect for automotive, aerospace and other industries where precision is critical.

Another notable benefit of CNC laser cutting is that the process is “burn-cut” without tool wear, where maintenance costs are lower over time compared to other cutting processes. This along with improvement in software has allowed these systems to automate the cutting sequence such that material loss is minimized further enhancing productivity.

Due to the constant advancing of technology, CNC laser machines continue to be among the most dependable and flexible tools for industrial metal cutting applications.

Acrylic and Plastics Engraving

Engraving as a whole is a booming trend across multiple sectors, which can be attributed to the precision it offers. With CNC laser machines, getting detailed marks and elaborate patterns on plastics and acrylics is effortless since they do not mar the surface or result in distortion because of overheating. The latest statistics indicate that the demand in advertising, decoration, and manufacturing of bespoke products will result in a 4.3% CAGR growth between 2023 and 2030 for the laser engraving equipment market.

Like most modern technologies, CNC lasers encompassing a variety of CO2 lasers have made it easier to operate on acrylic and related synthetic materials. Among the key benefits of CNC lasers is the accurate control and effortless handling of different thickness levels of acrylic, which incurs minimal material wastage. As an illustration, die boards with fine details and features can be engraved on sheets of acrylic as thin 2mm or as thick as 20mm with the same ease and precision.

The risk of brittle plastics cracking during laser carving is virtually diminished because pressed plastic materials are non-contacted which increases their durability. Modern software further supports the capabilities of CO2 lasers, increasing their popularity in CNC engraving acrylics.

CNC controlled laser under skilled hands can achieve engraving speeds up to 1,000 mm a second drawing out pieces accustom to the thickness of the acrylic and the intricacy of the carvings done on them. This advantage allows businesses to produce exquisite customized orders while having a great turn around time.

Handling Plywood and Wood

The use of laser machines for engraving and cutting wood are gaining much popularity due to their accuracy and adaptability. The capability of burning intricate designs without physical cutting tools enables numerous creative and industrial opportunities. With modern technology, laser machines can cut plywood up to 3/4 inch and as little as 1/8 inch thick, depending on the wattage used. For example, cutting 1/2 inch plywood with a 100 watt CO2 laser is possible with great edge accuracy and minimal charring, as long as the machine is tuned right.

Laser engraving on wood surfaces provide exceptional detail, up to 1,200 DPI. This efficiency is beneficial when creating detailed art pieces, personalized gifts, products branding or any other works. Primarily laser engravers and engrave birch, maple and cherry plywood because these woods provide flat surfaces and good engraving accuracy. Softwood such as pine and cedar are less common because they are uneven due to their grain and resin content which leads to irregular burns.

As per recent market insight, the global laser cutting market is expected to grow to \u00246.72 billion by 2030 due to the increasing demand in the woodworking and engraving sectors. In addition, the low cost of laser cutters along with small workstation models have made this technology available to small firms and even hobbyists, which has accelerated its adoption. Users can work creatively with wood and plywood as laser machines are integrated with design software such as Adobe Illustrator, CorelDRAW, and AutoCAD.

What Are the Benefits of Using a CNC Laser Engraver?

CNC laser engraving machines provide accuracy, speed, and productivity for cutting and engraving works. Doing both detailed and large-scale pieces of work is more efficient through these machines because they can produce consistent results. In addition to wood and plywood, these machines can also process acrylic and metal materials; therefore, they have a diverse applicational use. Moreover, CNC engravers are cost-efficient because they decrease manual work, material waste, and unproductive hours.

Meeting Modern Standards in Detail and Accuracy

Achieving a high level of detail and accuracy with modern-day machines is easily attainable as they possess new technologies and features. As an example, modern AI-powered control systems are enhancing accuracy by up to 20% AI compared to traditional ways of engraving and cutting. Reports suggest that CO2 and fiber laser cutters can achieve to airborne tolerances of ±0.001 inches, making these lasers highly suitable for critical manufacturers like jewelry, aerospace, and automotive industries.

In addition, improvements in power stability and beam quality have enhanced output quality while allowing operations to deliver faster speeds. Current systems cut standard materials at a rate of over 1.5 inches per second. Also, smart software helps in autopilot mode to optimize cutting paths providing savings of up to 30% on materials and time.

Modern technological advancements enable businesses to not only achieve precise and accurate outcomes, but also enjoy sustained operational efficiencies, firmly establishing laser cutting as an indispensable asset in contemporary manufacturing.

Efficiency in CNC Laser Cutting Processes

In my view, the efficiency in CNC laser cutting processes stems from the technology’s speed and precision alongside optimal resource usage. Elaboration using sophisticated software and high-performance lasers allow me to obtain meticulous outcomes while conserving resources and time. Streamlined operations with lower cost structures translates to long-term savings.

Versatility Across Different Applications

CNC Laser cutting boasts extraordinary versatility, making it a great asset across a wide array of industries such as automotive, aerospace, electronics, and medical devices manufacturing as they require precise components. As per the latest reports, the CNC laser cutting market is expected to expand globally at a compound annual growth rate (CAGR) of roughly 9.3 percent from 2023 to 2030, reflecting advanced manufacturing industry spend on diversity and precision.

What makes CNC laser cutting particularly special is that it can operate on all types of materials such as metals, plastics, wood, and composites. For example, in the automotive industry, it is common to use CNC lasers for cutting complex metal parts due to the low heat impact. Active lasers, fiber and CO2 lasers, are capable of very precise operations even on complex geometries. It is also possible to use AI and machine learning on CNC systems which now enables predictive maintenance as well as path optimization for cutting, conserving energy and improving product repeatability.

Its advantages certainly seem to be its edge. Research shows modern CNC laser systems have an operational speed of up to 20 meters per minute, depending on the material and its thickness. This type of efficiency ensures a reduction in energy expenditure. CNC laser cutting is an environmentally friendly solution. This type of advancement in technology also proves why advanced modern manufacturing is also dependable.

How to Maintain and Troubleshoot Your CNC Laser Machine?

- Routine Maintenance: Ensure to regularly maintain the exhaust system, lenses and mirrors of the machine to ensure peak performance and functionality. The accumulation of dust and debris can accurate the cutting precision.

- Check Alignment : Adjusting the laser beam from time to time helps in maintaining the accuracy when calibring the equipment. It is also a good practice to perform periodic checks.

- Monitor Consumables: Maintain operational efficiency by replacing consumable components like filters and nozzles which may lead to degraded performance over time due to excessive wear.

- Lubrication: To minimize the effects of wear and tear on moving parts, properly lubircate as per the guidelines provided by the respective manufacturer.

- Inspect for Damage: Look out for wear and tear on cables, connectors and other parts regularly to ensure they are in good working condition.

Regular Maintenance Practices

Establishing regular practices aimed towards maintenance greatly improves operational and overall equipment longevity. Actively maintaining and servicing all surfaces through debris clearing will decrease the chances of dust impacting performance. Ensure adherence to schedules for equipment inspections and servicing in accordance with guidelines provided by the manufacturer in order to mitigate issues proactively. Maintain a detailed log encompassing all maintenance activities for the equipment alongside parts changed and serviced to better understand the equipment history through patterns and recurring issues. As a result, reduce unexpected downtimes while maintaining optimal operational functionality.

Common Problems With A Laser Cutter And Their Solutions

As with any equipment, a laser cutter has to be problem diagnosed and serviced for maintenance systematically. The problem of misalignment of mirrors and or lenses is one of the most common problems to cut precision. To solve this issue, calibrating and checking optical components regularly is required. A worn out or failing tube is another problem which, insufficient working output cause, is often overlooked. Replacement of such tubes in a timely manner can conserve a lot of productivity. Overheating and poor cutting quality can also arise due to blocked air and coolant assist systems. Performing proper maintenance and cleaning helps prevent these issues. Not replacing obsolete software and firmware also seems to be a common practice. Staying current with software helps resolve needing technical support when most required. Identifying and solving these problems proactively assures reliable performance and efficiency.

Maintaining the Laser System

Correct maintenance of a laser system begins with following the manufacturer’s recommendations and implementing a set schedule. Data from the laser industry shows that more than 60% of lasers not working optimally can be attributed to failure to clean and fully calibrate important parts. For example, laser mirrors and lenses will dust and debris over time which will not only lessen the precision of cutting, but cause damage permanently over time. These optical elements can be cleaned using optical wipes and solutions which guarantee best results.

Routine checking of the system’s temperature is equally important. Research indicates that heat build-up is one of the dominant areas of concern for the degradation of laser tubes. The system’s operating temperature should never exceed 25 degrees Celsius, as doing so will drastically shorten its lifespan. Water chillers are an example of good coolant systems that can be checked regularly.

Surge protectors and UPS systems are recommended by experts to electrically safeguard systems. Protection from power spikes is not the only reason for employing these devices. Data from recent reports have shown that surge protectors can harm internal circuitry. Failure to monitor coolant checks regularly is another component of surge control that laser systems routinely forget to maintain.

Additionally, advanced technology has created devices that monitor and enhance the health of the systems electronically such as performance monitoring applications. These digital devices shed light on issues and alert operators in advance before grinding wheels heat up near critical operational levels.

Operators can maximize the lifespan, effectiveness, and accuracy of their laser systems by integrating proactive maintenance with technology and following professional advice.

Reference sources

- Exploration of Materials for Three-Dimensional NMR Microcoil Production via CNC Micromilling and Laser Etching. (Moxley-Paquette et al., 2024)

- Publication Date: 2024-08-08

- Methodology: Investigated the use of 5-axis CNC micromilling and UV picosecond laser etching to create 3D NMR microcoils from various copper-coated dielectrics (PMMA and glass capillaries). Compared the signal-to-noise ratio (SNR) and line shape of resonators made with different materials.

- Key Findings: Cu-coated PMMA provided the best SNR/line shape for larger coils (1.7 mm). Laser etching was more suitable for smaller coils (<1.7 mm) due to challenges in maintaining structural integrity with milled PMMA. Both laser-etched solenoid and saddle coils (1 mm O.D., 0.1 mm thick walls) showed excellent signal and identified metabolites in a 13C-labeled algae extract.

- Research on hybrid remanufacturing process chain of laser cladding, CNC machining and ultrasonic rolling for aero-engine blades. (Jia-Liang et al., 2024)

- Publication Date: 2024-01-01

- Methodology: This paper explores a hybrid remanufacturing process for aero-engine blades, combining laser cladding, CNC machining, and ultrasonic rolling. The specific methodologies within each process step are not detailed in the abstract.

- Key Findings: The abstract does not provide specific findings, only stating the research topic.

- Analysis of the Effect of Cutting Motion Speed in CNC Laser Cutting on Roughness and Accuracy. (Ghozali & Pangaribawa, 2024)

- Publication Date: 2024-02-27

- Methodology: Experimental study using CNC laser cutting on Eser plates of varying thicknesses (3 mm, 4 mm, 5 mm) and cutting speeds (1 m/min, 1.4 m/min, 2 m/min). Measured surface roughness (Ra) using a Surface Roughness Tester and accuracy using a Coordinate Measuring Machine (CMM).

- Key Findings: Cutting speed of 2 m/min yielded the best results for 3 mm thick plates (lowest Ra value and highest accuracy). Thicker plates resulted in lower accuracy. The frequency of roughness was a more significant factor than the period.

Frequently Asked Questions (FAQs)

Q: What is a CNC laser cutting machine?

A: The CNC laser cutting machine is a category of CNC machine that employs a focused laser beam to cut and engrave materials. It serves diverse industries that require laser engraving and cutting for critical operations.

Q: How does a diode laser module differ from other laser modules?

A: A diode laser module is a form of laser module that is widely adopted by engravers and CNC machines for cutting and engraving works. It is more compact than gas lasers and consumes lesser power making it useful for fine detailed work on many materials.

Q: What are the benefits of using a CNC router with a laser head?

A: A CNC setup with laser heads enables a user to switch from cutting and engraving to material processing. The machine will be able to perform sophisticated designs while remaining machine accurate and precise in its cuts.

Q: Can a CNC engraving machine be used for metal engraving?

A: Of course, a CNC engraving machine can use fiber laser cutting systems for metal engraving using appropriate modules. Just bear in mind that the machine’s power output must be calibrated properly for the engraver’s modules.

Q: Which safety precautions should be observed in using a CNC laser cutting machine?

A: The vital safety precautions in a CNC laser cutting machine incorporates the emergency switch, motion control systems, and protective covers that shield users from the laser beam.

Q: What is the importance of the controller in CNC laser operations?

A: The controller is responsible for the CNC laser’s motion control systems, power levels, and the sequence for executing cuts, assuring that all laser operations are done accurately and efficiently. A stable controller board is very important for the system.

Q: What is the list of materials a CNC laser cutting machine can work on?

A: A CNC laser cutting machine is capable of working on many materials like: timber, wood, acrylic ,PVC, and several metals ,having regard to the model of laser module and the power settings employed.

Q: In what other ways can the large working area of a CNC machine be advantageous for cutting and engraving?

A: The large working area makes it possible to process larger sheets of materials or several pieces at the same time, thereby improving the efficiency and productivity in performing these cutting and engraving tasks.

Q: What function does the laser head perform in a CNC laser cutting machine?

A: Its function is to concentrate and focus the high-powered laser beam to the material where cutting or engraving is needed. This is done efficiently and precisely if the laser head is of good quality, and thus its importance in the process cannot be underestimated.

Q: What are the benefits of having a plug and play laser for CNC machines?

A: With a plug and play, the user interface becomes much better since there is minimal or no laser head configuration. Instead, the user can focus on the work that needs to be done, so cutting or engraving can begin immediately after the module is connected.

- Is the Melting Point a Physical or Chemical Property? Unveiling the Science

- Master the Art of Laser Cut Acrylic and Plexiglass: A Comprehensive Guide

- Exploring the Best Paper Cutter Options Available Ranging from Heavy Duty to Guillotines and More

- Ultimate Guide to Fiber Laser Cleaning Machines: The Revolutionary Rust Removal Technology