Laser engraving, personal branding, and design creations have been taken to a new level, allowing intricate designs to be placed on different materials. Metals are particularly popular for many applications. Not all types of metals can be utilized for laser engraving, and this creates a challenge for businesbusinessespplications of the product, whether industrial or artistic; giftware, precision, and engraving quality will always depend on the laser engraver’s choice of metal. In this article, I will outline key principles and factors that must be considered when selecting metals for laser engraving, as well as most engraving methods. No matter where you are in your career, novice or expert, the information in this article will give you the edge to excel.

What Factors to Consider When Choosing Metal for Laser Engraving?

- Durability and Hardness

While selecting a metal for laser engraving, it is essential to analyze its durability and hardness. Metals like stainless steel, brass, and titanium are highly durable, yielding bright and enduring engravings. Softer metals like aluminum or copper are easier to engrave, but may prove to be less wear-resistant over time.

- Surface Finish

The microstructure of a metal impacts a laser’s engraving capabilities. A Polished or reflective surface requires extra steps to guarantee accuracy, whereas matte or coated metals result in consistent engravings.

- Compatibility with Laser Type

Some metals are more compatible with certain types of laser engravers. CO2 lasers, for example, work best with coated metals, while fiber lasers mark raw metals such as steel and aluminum better. The metal must be compatible with the equipment’s capabilities.

- Application or Purpose

Additionally, the purpose and goal of the item need to be taken into account. If the item is purely for decorative purposes, beauty and contrast take priority. If the item is functional or industrial, focus shifts to how resistant and readable it is.

Considering the factors explained above will help select the metal best suited for the laser engraving project while achieving the desired results in terms of precision and quality.

Type of Metal: Which Metals Are Best for Laser Engraving?

Reflectivity, malleability, and even some physical properties significantly impact the overall efficiency of metals when it comes to laser engraving. Based on their features, some metals perform better than others. Here are some of the top metals in laser engraving:

1. Stainless Steel

Stainless steel is one of the most laser engravable metals because of its strength and detail retention. Markings created through engraving processes are also very clean. This steel form remains relevant in medical devices, jewelry, and even the manufacturing industries, which correlates with its vigorous anti-corrosive properties. Industrial labels, branding, or custom engravings can be done on stainless steel because the markings created through engraving are sharp and cut deep.

2. Aluminum

Aluminum isn’t just versatile but also extremely light, which makes engraving easier. It’s also a key widely used metal in many software due to its low price and ease of customizing surface finishes. An anodized layer specifically increases engraving precision and contrast, which makes it the go-to choice in many industries, such as tools, promotional goods, and signage.

3. Brass

With a finish that resembles gold, brass stands out for its elegance and sophisticated looks. This makes it a suitable fuel for awards, plaques, and decorative items. Brass and laser engrave quite nicely, but there must be a middle ground regarding power and speed. Brass engraving does yield striking results with incredible details.

4. Titanium

Due to its lightweight, high strength, and unrivaled corrosion resistance, titanium is a metal of choice across all high-performance industries, including aerospace and medical equipment manufacturing. Laser engraving marks on titanium are durable and remain visible even under extreme conditions due to the high contrast it provides. Thus, titanium is ideal for applications where extreme reliability is needed.

5. Copper

Experts consider copper to have the highest thermal and electrical conductivity among all metals. While its reflectivity poses challenges when engraving with laser copper, its use in electronic components, plumbing fittings, and artistic designs justifies the difficulty. Precise carving into copper requires careful planning, but it certainly pays off due to the result.

6. Other Precious Metals (Gold, Silver, and Platinum)

Jewelry is among the most common luxury items that feature engravings of gold and silver. Like gold and silver, platinum is said to also respond well to laser engraving, allowing for intricate custom designs to be engraved. Although these metals are expensive, the stunning quality achieved with laser engraving and the precision that minimizes material wastage justifies the cost.

Laser Power: How Does It Affect Engraving Metal?

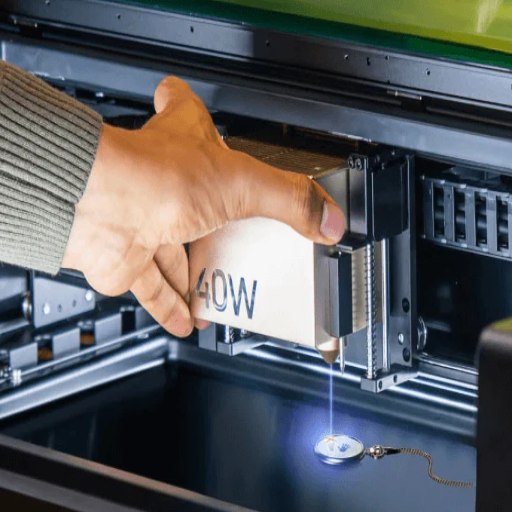

The capabilities of a laser for engraving on metal depend on its power, which determines the quality, depth, and speed of engraving. High-powered lasers are typically recommended for harder metals like stainless steel and titanium, as these metals have high thermal conductivity and melting points. For example, deep engraving on these metals requires a laser of at least 50 watts, while softer metals like Aluminum or brass will work with lower-powered lasers.

The power setting also determines the level of detail that the engraving allows for. Fine detailing that leaves a polished finish is ideal for low-powered settings, which are perfect for intricate designs or surfaces that need to appear visually stunning. Alternatively, high-powered lasers can quickly engrave deeper grooves, making them useful for industrial purposes like serial number marking or creating imprints that need to endure external stress.

Research indicates that the optimal settings for laser power differ per metal type and the result intended. This is particularly true for anodized aluminum, which requires only 10-30 watts for engraving, while polished stainless steel would require anywhere from 50-70 watts. Furthermore, other parameters such as speed and frequency could make the engraving more efficient, provided the proper laser power is used to prevent material overheating or distortion.

With proper laser power calibration, users can achieve their preferred depth and accuracy while also maintaining a high speed of execution on their metal engraving tasks.

Engraving Speed: What Should You Know?

In my experience, engraving speed is all about achieving a balance. When higher engraving speeds are employed, there is more time efficiency, but depth and detail, particularly on harder metals, tend to be sacrificed. Slower speeds, on the other hand, allow for detail and depth but increase production time. For maximum effectiveness, I strive to adjust the speed concerning the material and design specifics, along with the laser power and frequency settings.

What Are the Best Metals for Laser Engraving?

When evaluating what metals are best suited for laser engraving, the most important factors to consider are how well the metal reacts to the heat and energy of the laser. Durable metals – stainless steel, aluminum, brass, copper, and titanium – are recommended as these metals yield clean and precise results. Items such as tools and gifts are frequently made of aluminum and stainless steel, which are used for engraving and, most frequently, stainless steel for branding. Reflective finishes make brass and copper ideal for decorative pieces. Due to titanium’s strength and lightweight nature, it is often chosen for surgical instruments and jewelry. With the correct settings on the laser, these metals allow for high-quality engravings.

Stainless Steel: Why Is It Popular for Laser Engraving?

Due to its versatility, durability, and variety of applications, stainless steel has become one of the most favored materials for laser engraving. The presence of chromium in its alloy composition provides stainless steel with excellent corrosion resistance, which is essential for enduring engraving applications. In addition, stainless steel’s high heat resistance means that engravings can be made without compromising the material’s integrity or the design’s sharpness.

Stainless steel has a highly reflective surface, making laser engraving particularly effective as it enhances the markings’ contrast and ensures they are permanent. These benefits have placed stainless steel at the forefront in many sectors, including industrial naming plates and machinery tags, personalized gifts, and high-end signage. Data indicates that the global demand for stainless steel continues to grow alongside heavy industries, medical apparatus, and consumer goods. This stems from its practical qualities and the stainless steel’s professional and visually appealing finish.

Aside from its functional engravings, stainless steel can also be used for decorative patterns, logos, and artwork. Due to advances in fiber laser technology, engraving stainless steel has become both cost-efficient and practical. This laser technology, in particular, allows for faster engraving speeds while improving the clarity of finer details. The balance of practicality with design potential cements stainless steel as a premier material in the laser engraving industry.

Aluminum: Is It Suitable for Laser Engraving?

The ability to create highly contrasting and precise marks makes aluminum engraving a clear choice, with exceptional materials for laser engraving engravings. This is no different when considering anodized aluminum, where laser engraving works best with it. This type of aluminum has a layer that worsens contrast, yet makes the engraving extremely visible and sharp, making it appropriate for branding, labeling, or identifier plates.

Aluminum engraving is now done almost exclusively with CO2 and fiber lasers. Although fiber laser users praise it for its greater flexibility and precision, fundamental differences are still posed concerning oven their aluminum and CO2 lasers. Softer surfaces permit lower speeds and finer details regardless of whether the aluminum or harder metals are placed through the carving. The engraving improves with treated surfaces such as anodized or powder covered aluminum as they provide more outstanding sharpness and charm to the engraving.

According to those performed by industry experts, the effectiveness level when carving aluminum with a laser is exceptionally high. The efficiency is almost 1000 millimeters per second, depending on the machine used. Engraved aluminum, in any case, is known to be against harsh light, warm sun, moisture, and chemicals, depending on one’s environment. For this reason, it has become a commonly used material for industrial parts, outdoor signs, automotive, and so on.

Considering the extensive range of engraving applications, the properties of aluminum laser processing suggest that its low density combined with laser technology compatibility makes it a reliable and useful material.

Brass and Copper: Can You Laser Engrave These Metals?

Correct, one can laser engrave brass and copper, but special care must be taken because of their highly reflective and thermally conductive properties. Such characteristics may complicate the engraving process compared to other metals. I suggest utilizing a powerful and precise laser system tailored for these applications to achieve optimal results. Moreover, the engraving quality can be improved by covering the metal with some coating or applying techniques such as annealing.

How to Choose the Right Laser for Engraving Metal?

When contemplating which laser engraving machine to purchase, one must consider these factors as most relevant:

Metal Compatibility—One of the first factors to analyze is whether the laser will be effective with the specific metal you want engraved, such as brass, copper, aluminum, or steel. Generally, fiber lasers are recommended because of their effectiveness. These metals need precision and depth, which fiber lasers are ideal for.

Power Output—The type of metal you intend to engrave dictates the power requirements. Relatively low power is sufficient for softer metals, but highly reflective metals require high-power lasers because of their greater engrain depth requirements.

Precision and Detail—Sophisticated engravers use lasers with advanced systems for high resolution, which allows them to engrave small text and complex designs.

Cooling System—Powerful engraver systems often overheat. Lasers need a reliable cooling system to engrave for extended periods.

Budget and Durability—Balance the budget and total cost of ownership with the durability and lifespan of the laser system. The budget should allow for long-term investment.

By weighing the considerations mentioned above, one will likely achieve the engraving result that meets the set requirements.

Type of Laser: CO2 vs. Fiber Laser for Metal Engraving

In selecting between a CO2 and a fiber laser, comprehending their fundamental distinctions can help you choose the best option for your application needs, especially for metal engraving.

1. Compatibility Of Materials To Wavelengths FOR Lasers

CO2 lasers have a wavelength of 10.6 microns, which works well with non-metal materials such as wood, glass, and acrylic. CO2 lasers can engrave coated metals but may require some marking spray for raw metals. Unfortunately, due to poor absorption rates, most direct metal engraving with a CO2 laser is not ideal. Fiber lasers, in comparison, use a wavelength of roughly 1.06 microns, which works with most metals like aluminum, stainless steel, brass, and even titanium. These metals can be precisely and permanently engraved with a fiber laser.

2. Metal Engraving Speed and Efficiency

Fiber lasers are more efficient with a broader range of metals in terms of engraving speed. The high absorption rate of these metals ensures that marking will occur rapidly with minimal heat diffusion, thereby preserving the metal’s structure. Although CO2 lasers are versatile across various materials, their engraving speed on metals is consistently slower, and they require extra steps, resulting in a slowdown of processes.

3. Durability and Maintenance

Fiber lasers have a long operational lifespan of over 100,000 hours, require minimal maintenance, and have low operational costs. CO2 lasers, on the other hand, require more regular servicing due to additional components, such as mirrors and tubes, that require replacement over time. Due to decreased maintenance requirements, fiber lasers are more suitable for industrial applications where uptime is critical.

4. Costs

Unlike fiber lasers, which have a higher initial cost, CO2 lasers are more reasonable and appealing to hobbyists or beginner users for laser engraving since they can be utilized on various materials and have a much lower initial buy-in. Though, in the long run, CO2 lasers aren’t as efficient and cost-effective, specifically for businesses centered on metal engraving, they provide better value long term.

5. Precision and Detail

Fiber lasers are ideal for engraving intricate patterns like barcodes or small texts on metals due to their reasonably unmatched precision and detail. When working directly on uncoated metals, CO2 systems face challenges reaching the same level of detail attainable with fiber lasers.

Choosing the Best Laser Engraver for Metal Projects

When searching for the best laser engraver for metal engraving projects, it is imperative to consider several features that will contribute to optimal performance and successful results. Below are some of the primary considerations, along with some of the latest developments that self-explanatorily tailor your choice.

- Power Output

Efficiency is directly related to the power level of a laser engraver and its capability of working with metals. For heavy-duty metal engraving or cutting, it is prudent to use machines that are at least 20W powerful. On the other hand, thicker metals are best worked on using fiber lasers that range from 30W to 50W or even higher, providing unparalleled speed and depth.

- Precision and Wavelength

Metal engraving is best handled by Fiber lasers for the simple reason that their wavelengths are shorter (say 1.06 microns), meaning higher absorption for metals like stainless steel, aluminum, and brass. This allows for greater precision and detailing not only for industrial applications but also for fine, intricate designs.

- Compatibility with metal

Consider the types of metals you’ll be working with. Old fiber lasers easily engrave common metals like steel and aluminum. Make sure that any laser engraving system you use has features designed to lower reflection and energy loss for other metals, such as copper and gold.

- Engraving Speed and Efficiency

Modern fiber laser engravers often offer high-speed engraving, with varying speeds per model. Many can engrave between 1,000 and 2,500 mm/s. The increased speed of engraving translates to increased time saved in production environments, both for businesses and for devices.

- Lifespan of Components

Cost efficiency is vital, particularly in estimating equipment components’ service life. Fiber lasers commonly have prolonged downtimes, and as less than 100,000 hours of operational time is considered too frequent, heavily exceeding it drastically lowers needed maintenance and replacement costs.

- Cost and Budget Considerations

Implementation of industrial-grade fiber systems starts at around 3,000 dollars, frequently breaching 30,000 dollars with added customizability. While initial purchase costs increase over time, return on investment remains assured due to the lower maintenance costs of CO2 systems.

- Size and Work Area

Compact models of laser engravers are excellent for undertaking small-scale projects, though they may not match requirements in the work area for more significant undertakings. For extensive engraving tasks that outsize projects of non-industrial models, larger systems are available.

Considering these details and merging them with your particular requirements helps you narrow your options to a laser engraver that delivers precision, durability, and professional-grade quality for your metal works.

Laser Settings: What Are the Optimal Settings for Engraving Metal?

Setting optimal engraving settings for metal depends on various factors, such as the type of metal, the power of the laser, and how deep and refined the engraving needs to be. Fiber or CO2 lasers are generally suggested to be more effective for engraving metals.

- Power Settings

As with any machine, the laser’s power greatly influences the engraving’s depth and detail. Softer metals like aluminum may only require 30-50 watts, while harder metals, like stainless steel, titanium, or the more commonly used steel, will almost always require 50-100 watts or more for engravings to be precise and long-lasting.

- Speed and Frequency

Deeper engravings are achieved with slower speeds since the laser has more time to linger on the surface of the metal, but excessive slack can cause heat to build up, which is liable to damage or change the material’s color. Frequency settings, especially for pulsed fiber lasers, are just as important. For marking and engraving metal, more commonly used frequencies range from 20-80kHz due to the compromise between the level of detail and energy consumed.

- Focus and Spot Size

Engraving can be done precisely and consistently with the correct focus. Setting the laser focus to the material’s surface optimizes energy focus to that particular level, enhancing the quality of lines and detail on the work. Smaller spot sizes will enhance detail but require precision for setup.

- Additional Considerations

Engraving certain metals may require additional coatings or pre-treatments, such as anodized layers for aluminum. Moreover, air assist systems add value as they reduce smoke and debris that cloud vision during the engraving process. It is important to work with a sample piece to adjust the parameters that best suit the specific project.

Metals, whether for industrial purposes or under artistic flair, can be carved if the balance in power, speed, and concentration of laser focus is maintained at controlled levels to enhance the detail and strength of the etching.

What Is the Laser Engraving Process for Metal?

The metal engraving process utilizes a laser machining system that consists of a design and cutting module that uses intense laser light to mark the surface of the material. At first, the engraving is created on the surface of the engraving, and as it progresses deeper, the engraving becomes more detailed. This procedure usually consists of three steps: cleaning the surface of the engraving, preliminarily engraving, and customizing the engraving. It is widely accepted because it is accurate and it can reproduce intricately designed pieces without any faults.

Understanding the Engraving Process: How Does It Work?

Advanced technologies and sophisticated systems are prerequisites for laser engraving because related work is of high quality. The engraving procedure starts with a design creation using software like CorelDRAW or Adobe Illustrator. These applications enable users to create or upload templates with numerous details, which, in turn, are formatted to suit the requirements of the laser devices. After creation, the following process involves setting the parameters of the laser, which include speed, power, resolution, etc., according to the material being used. The lasers should have lower power for softer materials such as wood, while metals need stronger lasers to work effectively.

Recently developed laser engraving machinery uses either CO2 or fiber lasers, which best serve specific materials. Fiber lasers, for instance, are best when marking medals because of their efficiency and durability, while lasers for CO2 work well with organic materials like glass, leather, or acrylic. Data shows that fiber lasers can reach 7,000 mm/s, which makes these new devices suitable for production-oriented businesses.

One of the most important milestones in the technology’s development has been the introduction of laser engraving systems that focus automatically. Such systems focus on the best distance the laser should be with respect to the surface of the material and maintain that distance throughout the process. Moreover, newer cooling technologies have improved device lifetime and performance while greatly reducing the upkeep needs of the machines.

Laser engraving is used in a wide range of applications, from industrial manufacturing to personalized gifts. It is continually evolving with new technology, offering unprecedented levels of precision and customization.

Metal Surface Preparation: What You Need to Know?

Preparations done on metal surfaces are foundational for getting exact results when using engravers. This step ensures that preexisting, undesired conditions, contours, and surfaces that hinder precision accuracy will no longer exist.

- Cleaning Procedures: Cleaning procedures get rid of grease, dust, and corrosion. Any of the above makes engraving highly impossible. While using solvents such as isopropyl alcohol and acetone is good for cleansing active surfaces, it does not cause cross-contamination. Set intrusive layers such as rust can be dealt with through sandblasting or wire brushing techniques, which remove the hardened rust layer.

- Polishing: These techniques allow treatment until the desired grade is achieved. Focus polishing works by consistently delivering the laser on the plane of the metal.

- Surface Coating: Coatings enhance contrast and durability. Some engravings are enhanced by predefined counter-attack coatings. For example, stainless steel or aluminum can be treated using a marking spray to ensure stainless steel stays marked permanently.

- Graving Techniques: Getter techniques done using focused laser beams need specific humidity and temperature conditions to keep the accuracy of engravings intact. Operating under these conditions ensures that moisture oxidation and blurring are not seen.

- Analysis Based on Data: Effective surface finishing can enhance engraving accuracy by as much as 25% because of the reduced scattering of laser beams on clean, polished surfaces. Moreover, this optimization increases the work’s aesthetic value while decreasing the interruptions caused during the engraving process.

Achieving professional results that can withstand the test of time requires investing the effort to prepare the metal surfaces and ensuring that the final products are of uncompromising quality.

Finishing Touches: Post-Engraving Techniques

Once the engraving is complete, the engraving post-process techniques must be applied with care, as they dramatically affect the quality of the engraving. One of the more common procedures is cleaning the surface of the engraving to eliminate any engraved residue like metal shavings or soot that could blur the design. For intricately detailed engravings, removing small debris without tampering with the surface finish is critical. Ultrasonic cleaning seems to perform very well in this regard.

Covering metals with protected coatings extends the shelf life and slows the oxidation and corrosion processes. Transparent lacquers or anodization, for example, preserve underlying metal in terms of environmental attacks and improve their aesthetic value regarding the engraving blemishing the metallic surface. Newer research states that specific anodized finishes could extend the lifespan of some metals by 30%, a significant advancement in plastics and outdoor products.

Another very important procedure for engraved glass and acrylic products is polishing. Gentle buffing using a fine-grade polishing compound considerably improves the glass’s clarity and smoothness. For engravings that are a bit deeper, one could use sandblasting to obtain a more striking frosted look.

If followed meticulously, these post-engraving procedures can enhance the quality and longevity features of the engraved products, thus achieving the required benchmarks in aesthetics and durability.

How to Achieve the Best Engraving Results on Metal?

Begin the metal engraving process by selecting the metal type suitable for your project. Remember that aluminum is likely to be easier to engrave compared to stainless steel, a harder metal alloy. The metal surface must be adequately prepared, which entails cleaning any dirt, grease, or oxidation, as these contaminants will interfere with the quality of the engraving. Determine the most suitable technique, such as laser engraving for high precision and attention to detail or mechanical engraving for more pronounced cuts. Sharp tools or well-calibrated laser machines should guarantee accuracy, consistency, and a well-finished product. Lastly, a test engraving on a sample piece is performed to perfect the settings before the final product.

Choosing the Right Laser Settings for Optimal Results

Selecting the correct laser settings in terms of precision and quality for engraving tasks is essential. Laser power, speed, and frequency adjust according to engraved material. For example, higher power settings and slower speeds achieve clean edges on acrylics. Meanwhile, moderate speeds and power on wood prevent excessive charring or burning.

Data suggests changing the laser frequency improves engraved detail. For metals, a lower frequency prevents excessive heat, which may discolor or warp the specimen. Softer materials such as leather or fabric benefit from higher frequencies, which improve detail and prevent fraying.

Ensuring the correct focal length helps maintain accuracy and precision. Tests indicate an unfocused laser decreases engraving quality by upwards of 30 percent. Additionally, materials such as glass benefit from slightly defocusing the laser, reducing surface fractures.

Today’s laser systems include recommended default settings for different materials, which are helpful starting points. Adapting the settings to your machine’s capabilities and environmental conditions, like the room temperature or humidity, can improve engraving quality further.

Factors Influencing Engraving Quality: What to Consider?

- Material Choice

Different materials require distinct methods of engraving, which in turn results in various finishes. For example, wood and leather are softer materials and can be easier to engrave as they have lower resistance; glass and metal, on the other hand, may need stronger laser power for accurate results. Evidence collected by the industry suggests that CO2 lasers are better suited for non-metal materials, while fiber lasers are more effective on metallic surfaces.

- Speed Settings and Laser Power

There needs to be a trade-off between laser power and speed. Higher power settings, while working with more delicate materials, tend to face the risk of burning or distorting. Cutting tougher materials does provide more clarity and depth with higher power settings. Softer materials yield better detail when using lower-powered settings with slower speeds. Newer evidence points to the ideal setting being within the 20-80% range if the goal is to have complete control over the material.

- Focus and Spot Size

In carving designs, maintaining laser roughness needs to be done with care to keep the engraving precise. The best results radially come from smaller spot sizes, as they allow better detail resolution, which is important for fine text and intricate features. Based on the recommendations, many industry providers are retouching focus periodically to ensure smooth and stable output across different projects.

- Environmental Conditions

Factors such as temperature, humidity, and air circulation are increasingly relevant, considering their impact on engraving quality. For example, excessive moisture may soften materials, such as wood, affecting the engraving depth or burn marks. It is advisable to operate in conditions with little variation for the most consistent results.

- File Resolution and Design

The resolution and quality of the design file determine the outcome of an engraving. Higher-resolution files featuring sharper lines tend to engrave more distinctly. Due to their precision and scalability, vector files are recommended instead of raster images.

- Maintenance of the Laser System

With consistent maintenance, the quality of the engraving produced and the lifespan of the equipment used will hold up. Maintenance involves cleaning lenses and mirrors, verifying they are correctly aligned, and replacing old parts. Neglecting these measures will eventually produce less precision and clarity in the engraving output.

By paying close attention to these factors, operators, along with constant iteration of the input values, will protect the engraving from quality issues while providing precision that meets varying project requirements.

Reference Sources

-

Overview of Laser Technology in Manufacturing1:

- Key Findings: This study highlights the versatility of laser technology in cutting and engraving metals. It emphasizes lasers’ precision, speed, and adaptability for various metal types, including carbon steel and aluminum. Challenges like reflectivity in metals like aluminum and copper are also discussed.

- Methodology: The research comprehensively reviews laser applications, focusing on industrial uses and the physical principles of laser-material interaction.

-

3D Printing and Laser Sintering Techniques2:

- Key Findings: The paper explores the integration of laser sintering in additive manufacturing, particularly for metals like titanium and aluminum. It discusses the importance of material properties and laser settings in achieving optimal results.

- Methodology: A review of advancements in direct metal laser sintering (DMLS) and selective laser melting (SLM), focusing on their applications in aerospace and medical industries.

-

Deep Learning in Steel Research:

- Key Findings: This study introduces machine learning models to enhance the analysis of steel microstructures. It demonstrates how laser-etched samples can be analyzed more effectively using AI, improving the understanding of material properties.

- Methodology: The research employs multimodal microscopy and generative adversarial networks (GANs) to transform low-resolution images into high-resolution ones, aiding in precisely characterizing steel surfaces.

- Top Color Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is metal laser engraving?

A: Metal laser engraving is a process that uses a laser engraving machine to etch or mark designs, text, or images onto the surface of various metals. This technique allows for high precision and durability in the engravings.

Q: What types of metals are popular for laser engraving?

A: Popular metals for laser engraving include stainless steel, aluminum, brass, and copper. Each type of metal has different properties that affect the engraving process and the final appearance.

Q: What is the best laser for engraving metal?

A: The best laser for engraving metal typically includes fiber lasers, as they are particularly effective for marking and engraving on metals due to their wavelength and energy output.

Q: How do I clean the metal surface before laser engraving?

A: To ensure the best results, the metal surface must be thoroughly cleaned before laser engraving. Use a suitable cleaning solution to remove dirt, oil, or contaminants that may affect the engraving quality.

Q: Can I laser engrave metal with a CO2 laser?

A: While CO2 lasers can be engraved on some metals, they are less effective than fiber lasers for most metal applications. Fiber lasers are generally recommended for better results in laser metal engraving.

Q: What is laser etching, and how does it differ from laser engraving?

A: Laser etching removes a thin layer of the metal surface, creating a design that is slightly raised compared to the surrounding area. In contrast, laser engraving involves deeper penetration into the material, resulting in a more pronounced design.

Q: How does the engraving area affect the laser engraving process?

A: The engraving area determines the design size that can be marked on the metal. Larger engraving areas allow for more intricate designs but may require a more powerful laser and careful handling to maintain precision.

Q: What factors should I consider when choosing the right laser marking machine?

A: When selecting a laser marking machine, consider the type of metal you will be working with, the desired engraving depth, the size of the engraving area, and the machine’s specific engraving and cutting capabilities.

Q: What is laser annealing, and how is it used in metal laser engraving?

A: Laser annealing is a technique for changing the color of a metal surface without removing material. Laser marking often uses it to create color engravings on metals, adding an aesthetic appeal to the design.