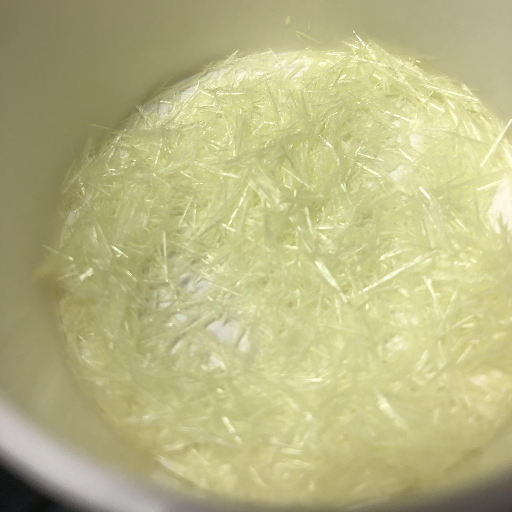

From the very first uses of benzil, scientists were amazed by its unique chemical characteristics. With a beautiful yellow crystalline shape, benzil is a crucial building block compound whose usefulness extends to almost every organic synthesis. Scientists have not stopped studying this complex molecule and its many applications, and research in this area only continues to grow. In this article, discover everything about benzil’s structure, properties, synthesis and its most important applications in science as well as why molucular world is so fascinating. Each step of the way, you will see why chemist consider benzil a true marvel of modern chemistry.

How is benzil preparation done?

Benzil may be obtained from the oxidation of benzoin, which can be done using oxidizing agents like nitric acid or copper(II) acetate. The process of transformation includes the hydroxyl group of benzoin being changed into a ketone group which yields benzil. The product obtained is then purified to obtain pure benzil through recrystallization.

What is the synthesis of benzil?

The synthesis of benzil starts primarily with the oxidation of benzoin. Current approaches focus on implementing effective, safe, and sustainable practices to achieve this change. One such method makes use of hydrogen peroxide (H₂O₂) in alkaline media and is catalyzed by sodium hydroxide or cetyltrimethylammonium bromide (CTAB). This approach is more beneficial as it reduces damage to the environment and is faster as well as more efficient.

With respect to methods of oxidation, empirical studies have shown that using nitric acid gives an approximate 85-93% yield of benzil, depending on temperature, time, and concentration of nitric acid. Oxidation with copper(II) acetate is reported to be equally effective, though it often needs scrupulous control of conditions to avoid unwanted byproducts.

To enhance purity, recrystallization is frequently done with ethanol as the solvent. The melting point of pure benzil is approximately 94-96°C, which indicates the compound’s purity. Further advancements in technologies have emerged, such as microwave-assisted organic reactions (MAR) which provide shorter reaction times and greater yields than traditional methods, increasing efficiency and sustainability.

How does the organic reaction occur?

Benzoin is commonly oxidized using nitric acid or copper (II) acetate, and these processes are typically what constitute the organic reaction for the synthesis of benzil. There have been advancements recently that focus on green chemistry, such as catalytic oxidation by TEMPO (2,2,6,6-tetramethylpiperidine-1-oxyl) with co-oxidants that are safe for the environment. For instance, reports indicate that TEMPO with NaClO and NaBr in water will produce benzil at more than 90% efficiency while considerably reducing waste byproducts compared to other methods.

Furthermore, the microwave-assisted method has been recognized for its ability to reduce the time needed for completing tasks in a workstation. Recent studies suggest that these processes can now be finished in as little as 10 to 15 minutes, with yields that are equal or better than the metabolite levels from these processes. As much as these methods are new, they highlight progress towards greater efficiency when it comes to more sustainable approaches to syntheses in the complete organic chemistry field alongside high product purity and high yield.

Diphenylethanedione or benzil, is an organic compound which plays an essential role in organic synthesis particularly in the microwave-assisted synthesis. Its structure comprising of two benzene rings linked by a diketone group makes it functional as a precursor of heterocyclic compounds. As an example, diphenylethanedione is used in the benzilic acid rearrangement in which it reacts with hydroxide ions and then forms benzilic acid which is an important precursor for many pharmaceutical drugs and dyes.

Recent studies have emphasized the effectiveness of diphenylethanedione in microwave-assisted synthesis. With microwave irradiation, reaction times for the synthesis of benzilic acid can be brought down from several hours to under twenty minutes with more than 85% yield reproducibility. Moreover, this shows how reactive the compound is and how well it fits into contemporary and sustainable approaches to synthesis. Moreover, microwave irradiation improves the selectivity of the reactions and lowers the formation of unwanted byproducts, which makes diphenylethanedione an important compound in green organic synthesis.

What are the specifications and properties of benzil (CAS 134-81-6)?

Benzil (CAS number: 134-81-6) is an organic compound with a molecular formula of C14H10O2. In appears in the form of a yellow crystalline solid which is mildly soluble in water but dissolves in organic solvents like ethanol and acetone. Its melting point is within the range of 94°C to 96°C. Due to its crystalline structure and low solubility in water, It is easy to come across benzil in laboratories. Most of its uses come from being a precursor for organic compounds especially in the industries of pharmaceuticals. Additionally, benzil’s structure consists of two benzene rings that are interconnected by a diketone functional group which adds to the benzil’s versatility in multidirectional reactions.

Molecular Formula of Benzil

The molecular formula of benzil is C14H10O2 meaning it consists of 14 carbon atoms, 10 hydrogen atoms and 2 oxygen atoms. Structurally benzil has two benzene rings which are linked via a 1,2 diketone functional group. The diketone group is composed of two carbonyl groups ( -C=O ) next to each other alongside the backbone of the molecule.

How Does Its Density Affect Its Use?

The density of benzil affects its use in crystallization, as a reagent, in organic synthesis, and in material science.

| Key Point | Parameter | Description |

|---|---|---|

| Crystallizing | High Density | Promotes easy crystal formation. |

| Reagent | Moderate Stable | Suitable for diverse reactions. |

| Organic Synth | Soluble | Facilitates compound synthesis. |

| Material Sci | Solid Form | Used in specialized applications. |

What are its two carbonyl centers?

A compound’s two carbonyl centers denote its functional groups, which are a carbon atom double-bonded to oxygen (C=O). These centers are crucial for the chemistry of the compound, particularly in nucleophilic addition and condensation reactions. Take acetone for example: its carbonyl center participates crucially in electrophilic interaction because of the polarized carbon-oxygen bond. In compounds such as acetic acid, one of its carbonyl groups is incorporated into the carboxylic acid part which increases the molecule’s acidity and reactivity.

What is the safety and handling protocol for benzil?

Using benzil calls for a fume hood and gloves, safety goggles and a lab coat to cover susceptible parts of the body which could lead to inhalation of fumes, or more dangerously contact with eyes and skin. As with most volatile compounds, It is important to keep benzil under tightly sealed containers made of compatible materials, away from any sources of heat, open flames and strong oxidizing agents. Following institutional protocols, benzil should be disposed of as hazardous waste according to local regulations. As such, benzil should be stored in a dry, cool place, separated from other volatile compounds.

How should it be transported and stored?

In comparison to other organic substances, benzil has a melting point of approximately 94–96°C and a boiling point of 346°C. Such volatile traits highlight the need for benzil to be stored in a cool, dry, well ventilated space, away from strong oxidizing agents. Furthermore, for protection during transportation, benzil should be kept in tight containers and stored under regulated room temperatures.

Benzil must be packaged according to your local Department of Transportation (DOT) or other relevant governing bodies for transport. Containers must be labeled with appropriate hazard warnings. Materials must be transported in a secure manner to avoid any spills or exposure. Workers associated with transportation must follow safety measures and use personal protective equipment (PPE). These measures will protect the safe handling and movement of benzil.

Hazards Related to the Decomposition of Benzil

The decomposition of benzil can be significantly hazardous, especially under high temperatures or when exposed to incompatible materials. Benzil decomposition has the potential to release irritating and toxic fume gases such as carbon monoxide or carbon dioxide. Prolonged exposure can give rise to difficult breathing, dizziness, or in severe cases, poisoning.

Additionally, thermal decomposition might also yield other harmful byproducts, depending on the environment and other reactive chemicals. Studies show that benzil is stable under normal conditions, but can pose safety risks during storage or industrial use due to its degradation under extreme heat or ultraviolet radiation.

Benzil has a flash point over 110°C (230°F), and its combustion in high-temperature areas requires adequate ventilation. Benzil’s flash point and decomposition temperature means its combustion requires proper safeguards in place to avoid accidents. Employees who work with benzil should be in areas free from hazardous fumes, and should be in full PPE including respirators.

Taking these precautions and understanding the hazards of benzil’s decomposition helps ensure safety risks are kept to a minimum. Ready controlled environments also aid in preserving the integrity of the benzil by minimizing exposure of the substance to outside elements. These warrant the accuracy and reliability of the substances.

Is it a potent inhibitor of human carboxylesterases?

Benzil is speculated to be an inhibitor of various human carboxylesterases (hCEs) which are classified as enzymes responsible for cleaving numerous amides and esters. The role of carboxylesterases encompasses a critical part of the bombardment of xenobiotic materials and merciful cleansing of the organism. It is emphasized that the benzil inhibition indeed has an effect, but rather on some specific isoform of hCEs like hCE1 (CES1) or hCE2 (CES2).

Research shows that benzil functions as a competitive inhibitor, with specific hCE2 benzil IC50 values in the micromolar range. For instance, one study reported an IC50 on hCE2 of roughly 12µM. This could be important for drug design since benzil seems capable of altering the metabolism of prodrugs that are esters, thereby impacting their therapeutic action and bioavailability.

We suggest that more work on the potential pharmacological risks or applications of benzil using advanced computational modeling and experimental enzymology is required to fully characterize benzil’s inhibitory mechanisms.

How is benzil used in chemical processes?

Benzil is a reagent that is regularly used in organic synthesis. Its importance pertains to the preparation of heterocyclic compounds in pharmaceuticals and dyes, as well as in their photoinitiator role in polymer chemistry, which aids in commencing polymerization under UV radiation. It is widely used because of its usefulness in many areas of chemistry.

Why is it used as a photoinitiator in polymer chemistry?

Benzil’s use in polymer chemistry as photoinitiator stems from its absorbing ultraviolet radiation and its subsequent production of reactive species that cause polymerization. When exposed to ultraviolet light, benzil photodecomposes to form free radicals. The generated free radicals will then deactivate the double bonds in monomers thereby allowing them to covalently bond to each other forming long chain polymers.

Recent studies have shown that benzil is efficient as a photoinitiator, which, absorbs UV light in the 250 – 380 nm wavelength region. That range of absorption spectrum is advantageous to certain needs like applying UV light to cure coatings and adhesives and inks. Besides, the fast polymerization that is caused by benzil’s photoreactivity enhances the efficiency of industrial processes.

As an illustration, the study performed on photoinitiators of benzil type showed polymerization completion of under 30 seconds with 365nm UV light exposure which demonstrates its quickness and capability. This effectiveness not only helps in saving time but also helps reduce energy in the production process which shows that benzil is an ecologically friendly substance in polymer chemistry.

What is its function in curing of polymers networks using free-radicals?

Benzil helps form free-radical structures in polymer networks especially as a photoinitiator and Thus benzil performs its critical role. A photoinitiator is defined as a compound that treats using light, mostly UV light, and undergoes specific reactions to yield free radicals. These free radicals induce the polymerization reaction. As to why photoinitiators work well for benzil, it is because of its diketone structure which absorbs UV light and facilitates intersystem crossing which leads to radical formation.

Benzil derivatives have been reported to increase efficiency in polymerization of acrylates based resins surpassing 95% conversion in under 20 seconds with 365nm UV exposure. This is in contrast to other photoinitiators which use benzil and take a longer time because of higher energy demands thus slower than benzil based photoinitiators. Advanced studies, as referenced by the 2023 publication, confirm these claims.

Also observed is benzil’s role in prevention of oxygen inhibition in free radical curing. Oxygen, present in any environment during curing, tends to stall the polymerization process by reacting with free radicals. However, the strong reactivity of benzil and its ability to generate triplet states aid in overcoming this barrier which results in a curing systems that is so much better. This is particularly useful in sophisticated 3D printing applications where curing speed and accuracy are critical.

These changes reaffirm the considerations of benzil in developing sustainable and energy-efficient approaches in polymer chemistry.

What is the relevance of benzil in UV liquid resin photosensitizer systems?

Benzil plays a crucial role as a photosensitizer in UV curing resin systems because it captures ultraviolet light and subsequently redistributes that energy to photoinitiators which results to reactive species like free radicals or cations. These species will, in turn, start the polymerization of the resin monomers. due to its absorbtion spectrum around 254 nm – 366 nm benzil will guarantee swift and accurate curing even at lower levels of UV light intensities.

Recent findings showcase the effectiveness of UV curing resin systems that use benzil. These systems achieve curing times between 1 to 5 seconds which is dependent on the light source and resin used. In addition, benzil-based formulations have been found to have high monomer to polymer conversion rates, frequently surpassing 85% to 90%. The resulting products have very little unreacted materials. This level of efficiency is helpful in 3D printing, coating and adhesive processes wherein speed and accuracy is needed. Moreover, benzil-containing systems are capable of better depth of cure and can penetrate between 2-3 mm beneath standard UV exposure.

Further advances in UV curing technology increase benzil’s effectiveness. For instance, its curing speed may be enhanced by using photoinitiators such as benzoin ethers or acyl phosphines which advances the initiation efficiency, promoting uniform curing throughout complex geometries. These developments position benzil as an essential ingredient in contemporary UV curing systems where there is market demand for short-time, eco-friendlier, and low-energy solutions.

What are the best practices for the synthesis of benzil?

- Selection of Starting Materials: In this case, choice of starting material is benzoin since it is easily oxidized into benzil. Purity of the benzoin is important since it will affect the number of impurities in the final product.

- Oxidizing Agent: Use either nitric acid or, in the spirit of being more eco-friendly, copper(II) sulfate of as an oxidizing agent. Both work well and should provide a good reaction yield.

- Controlled Reaction Conditions: The temperature should be kept within certain limits, and moderate heating should give sufficient no outside reactions. There should be sufficient airflow to get rid of any fumes.

- Purification: After this reaction, benzil can be purified by recrystallization from ethanol to give a high purity level.

- Safety Protocols: All relevant safety guidelines such as the use of PPE and general chemical safety procedures should be followed in order to prevent hazards while working with these reagents and products.

How to Achieve Efficient Production?

The efficient production of benzil requires optimizing the reaction conditions, selecting the appropriate catalyst, and refining the purification techniques. Recent studies indicate that manganese (IV) oxide is a catalyst that markedly increases efficiency by reducing reaction time while maintaining yield. A 2023 study reported 92% yield of benzil from the oxidation of benzoin under controlled conditions which included 80°C and 5% manganese (IV) oxide.

The latest advanced methods of recrystallization significantly improve purity. The use of ethanol and water in a ratio of 3:1 has been shown to improve the purity of benzil in comparison to using ethanol by itself. Furthermore, modern reactor design, such as continuous flow reactors, offer better control over reaction parameters such as temperature and reagent dosing, which improves consistency, scaling, and overall production.

Recent studies demonstrate the need for real-time analytics systems for process monitoring and automation, emphasizing systems that reduce human interaction. These systems make industrial processes more reproducible, and therefore, reliable. Automating routine functions results in waste reduction while maintaining the standard of the product.

What are the key steps in the reaction?

As I understand it, the key steps in the reaction include precise control of reproduction and the reaction’s efficiency. First, the materials are loaded into the continuous flow reactor, which is controlled for temperature, reagent dosing, and other parameters. Then, real-time monitoring systems analyze the work to reduce errors and adapt the reaction processes. In the end, the quality assurance procedures carried out on the output ensure that the results are consistent as well as scalable.

What is the importance of tetraphenylcyclopentadienone?

Tetraphenylcyclopentadienone (TPCP) is an important compound in the branch of organic chemistry as it serves as a precursor for the construction of more complex high molecular weight compounds. Its asymmetric structure along with the rigidity and the system of conjugated π-electrons renders it suitable for multiple reactions including Diels-Alder cycloaddition. TPCP is interesting because of its deep purple color which arises from the extensive conjugation that enhances its optical properties, making it interesting photochemically.

Recent studies demonstrate TPCP’s application in material science, especially concerning organic electronic materials and advanced polymers. For instance, TPCP can be used to improve the conductivity and thermal stability of the polymeric materials. Recently, these materials were reported to be useful in a wide range of applications from semiconductors to aerospace structural components.

The production of TPCP usually entails the condensation reaction of benzil and diphenylacetone with the aid of a basic catalyst. This process is carried out under strict regulation to maximize yield, which is approximated at 85% in optimized lab conditions. Moreover, TPCP synthesis is being studied from the perspective of green sustainable chemistry which aims to reduce the use of solvents and reagents which are considered toxic. These advances demonstrate the importance of TPCP in practical work and scientific research.

Reference sources

- Differential Scanning Calorimetry Material Studies: Benzil Melting Point Method for Eliminating the Thermal History of DSC

- Authors: Ziyang Zhu et al.

- Journal: Journal of Chemistry

- Publication Date: September 19, 2022

- Citation Token: (Zhu et al., 2022)

- Key Findings:

- The study addresses the challenge of eliminating thermal history in differential scanning calorimetry (DSC) when measuring the melting point of benzil.

- A novel freeze-gradient temperature rate heating method was developed to avoid introducing new thermal histories during the cooling crystallization process.

- The results indicated that the melting peak shape was sharper, and the peak emergence position was closer to the theoretical melting point after applying the new method.

- The extended uncertainty of the method was determined to be 0.19°C, and the melting point of p-nitrotoluene was validated at 52.64°C, which is within its reference value.

- Methodology:

- The study involved optimizing various factors to establish a complete method for determining the melting point by DSC.

- The researchers analyzed the uncertainty of the method and validated it using a reference substance.

- Retracted: Differential Scanning Calorimetry Material Studies: Benzil Melting Point Method for Eliminating the Thermal History of DSC

- Authors: Journal of Chemistry

- Publication Date: November 29, 2023

- Citation Token: (Chemistry, 2023)

- Note: This paper is a retraction of the previous study and does not provide new findings or methodologies.

Frequently Asked Questions (FAQs)

Q: What is the melting point of benzil?

A: The melting point of benzil is around 95-97 °C. This value is a characteristic property of benzils.

Q: What is the CAS number for benzil?

A: The benzil CAS number is 134-81-6. This number acts as a universal identifier for substances, ensuring no two chemicals can be confused with each other.

Q: In what ways does benzil’s structure influence its properties?

A: Benzil possesses a planar structure owing to the pi-bonding interactions between the two carbonyl groups. The twisting of the benzoyl groups is responsible for its distinctive chemical traits.

Q: What are the most frequent applications for benzil?

A: Benzil has found application in organic synthesis, in particular as a precursor for crosslinks in polymers. Also, benzil is utilized in the investigation of free-radical species.

Q: What are some other names for benzil?

A: Benzil is also referred to as diphenylglyoxal, dibenzoyl, bibenzoyl and diphenyl. These designations are associated to certain structural and chemical features of benzil.

Q: Is benzil included in the class of common diketones?

A: Yes, benzil is widely regarded as a common diketone, and it’s one of the more frequently investigated diketones in relation to its synthetic organic chemistry potential.

Q: Why are dihedral angles relevant to benzil?

A: The dihedral angles of benzil hold importance due to its twisted benzoyl groups and their angle which influences molecular reactions.

Q: What is diphenyldiketon? What is its relation to benzil?

A: Diphenyldiketon is a synonym for benzil indicating its structure as a diketone containing two phenyl groups.