The step ensuring precision and efficiency with any bending undertaking is choosing the correct pipe and tube bender. They are used in construction, manufacturing, and even DIY tasks; hence, they come in different types designed for varied materials, project sizes, angles, and more. This guide seeks to help users understand the crucial deciding factors such as material, functionality, and features to ensure the best choice is made. An understanding of these factors guarantees that decisions are made in line with your objectives and project requirements.

What is a Pipe Bender and How Does it Work?

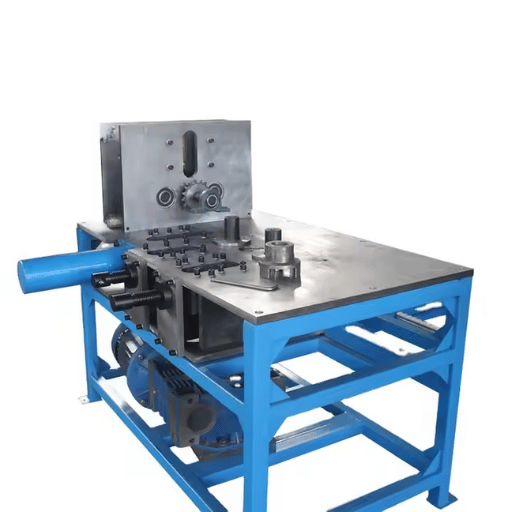

A pipe bender is a specialized tool that forms precise bends in pipes and tubing while preserving their structural integrity. These devices operate by mechanically or hydraulically forcing the pipe into the desired angular or curved position. Depending on the model, some pipe benders incorporate a die set to direct the bending of the pipe to enhance accuracy. Benders produced these days have gone a step further to improve accuracy and efficiency by including digital controls and programmable settings.

Choosing a Pipeline Bender: Consider the Guidelines

When picking a pipeline bender, certain factors like material type, bending radius, and capacity must be taken into account. As an example, steel, aluminum, and copper each have different settings that need to be applied during bending to avoid causing damage. Also, the bending radius is one of the most important aspects that needs to be measured in either inches or millimeters and needs to be compliant with the industry to make certain that the pipe can still be used afterward.

As industry statistics show, the permissible bending radius of steel pipes is generally considered to be between 1.5D to 5D. Here, “D” represents the pipe diameter. This means that for a steel pipe with a two inch diameter, the minimum bending radius is 3 inches (1.5D). Furthermore, the modern hydraulic pipe bender has the capability to exert forces of more than 10,000 psi which allows to handle with the pipes of 8 inches diameter depending on the model.

Precision is very critical with modern pipe benders factor. Advanced pipe benders that are equipped with CNC (Computer Numerical Control) technology can get tolerances of as tight as ±0.5° of angle which is the minimum deviation from the designated angle. This level of precision is critical in the aerospace and automotive industries where the exact measures and the entire system works together depend on a lot. Having these details in mind guarantees the proper selection of equipment, proper operations with the machinery, and in compliance with the project specifications.

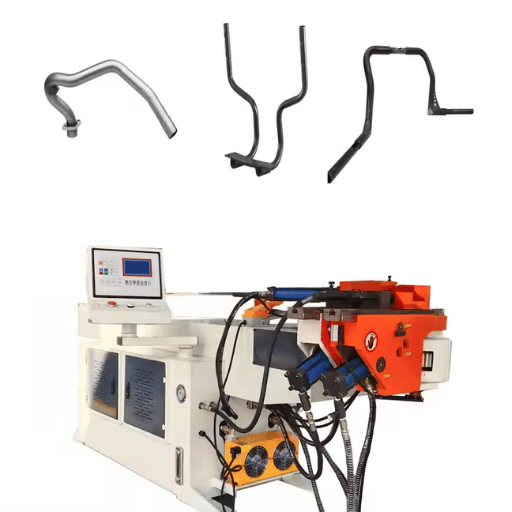

Different Types of Pipe Benders

Pipe benders are divided into classes depending on how the work is done, the type of material they are meant for, and their usage. Here is a basic description of the most common types:

Operation: Manual lever and hand operated.

- Applications: Handy for soft materials like copper and aluminum for crafts and low volume routine work.

- Advantages: Portable and the cheapest option available.

- Limitations: Very inaccurate and bulky for a work of this nature.

- Operation: Minimum effort required from the operator and the bending is done via hydraulic power.

- Applications: Used by plumbers, builders or manufacturers who work with moderate duty pipes.

- Advantages: Bending and working on hard materials like steel is easy due to great bending power.

- Limitations: Constrained to being the worst option, they are heavier and cost more.

- Operation: Electric motor driven, provides uniform bending without limits.

- Applications: Appropriate for big tasks that have to be done repeatedly with uniform accuracy.

- Advantages: Offset manual work and enhance productivity.

- Limitations: Need lots of cash to obtain and is restricted to being plugged into a socket.

- Operation: Completely automated, digitally operated in terms of control through programming.

- Applications: Generally used in precise sectors like aerospace, automotive or shipbuilding.

- Advantages: Immeasurable precision, high repeatability, intricate bending.

- Limitations: Technical control to work limits due to high starting expenses.

- Operation: Bend pipes around a fixed radius die with precision.

- Applications: Needed for installing consistent bends for handrails, river cages and furniture frames.

- Advantages: Diameter consistency without deformation. Suitable for thin-walled pipes.

- Limitations: Only certain bend radii and materials.

- Operation: Add a mandrel inside on the pipe being bent to prevent crushing or collapsing.

- Applications: Helpful for creating bends in flexible or thin-walled pipes, exhaust systems commonly use it.

- Advantages: Better than others, smooth distortional bends.

- Limitations: More complicated, more setups.

Understanding the operational modes and the pros and cons of each type of pipe bender allows the users to tailor to his preferences most efficiently with regard to the project details and materials needed.

The Role of Hydraulic and Manual Benders

The accuracy of bends, even for complex shapes, is a hallmark of skill achieved by hydraulic benders because of consistent force application. The results obtained from manual benders, on the other hand, are far less accurate because of reliance on operator skill to control various factors affecting curvature.

Manual benders are more appropriate for softer materials such as aluminum and copper because of the relatively low force needed to bend such materials compared to steel or thick wall pipes. The impressionability of pipes is smaller than that of the manually controlled benders.

In terms of operational effectiveness, manual benders perform slower than their counterparts and therefore are better suited for custom smaller scale projects, while hydraulic benders are better suited in high-demand manufacturing industries due to the short amount of time per unit. It can be argued that employing a hydraulic bender can lower the average time per piece by 30-40%. Therefore manual hydraulic benders should be seen as more flexible in operation.

The cost of a hydraulic bender typically falls between $500 and $5,000, determined by their complexity. On the other hand, manual benders are more affordable, priced between $100 to $500. Regardless, the cost effectiveness and efficiency provided by hydraulic systems during large-scale operations make them the optimal choice.

Regular inspection and maintenance of seals, hoses, and hydraulic fluid are essential for the performance of a hydraulic bender. Pro-active Manual benders do not require as much maintenance –usually only needing periodic lubrication and wear and tear assessments.

All factors can enhance decision making regarding the operation demand of the pipe bender such as precision, capacity and cost efficiency.

How to Choose the Best Tube Bender for Your Needs?

Key Features of Tube Bending Machines

In operational or project requirements, the following key features are of utmost importance when selecting a tube bender:

Material Compatibility: Determine if the machine is capable of processing materials such as stainless steel, aluminum, or copper.

Bend Radius: Assess the minimum and maximum bend radius the machine can achieve.

Tube Diameter Range: Verify if the bender can handle the required range of tube diameters.

Manual Benders:

Best suited for low-volume jobs.

These machines are the most affordable, portable, and easy to carry around.

Hydraulic Benders:

Best suited for medium to high-volume projects.

They are capable of providing a greater bending force required for tougher materials.

CNC Benders:

Best suited for high-precision, high-production needs.

Have capabilities for automation and complex bending operations.

Cycle times must be evaluated to ensure alignment with project deadlines and productivity goals.

Look for advanced functionalities such as multi-radius bending and bends executed simultaneously.

With programmable settings, CNC benders are usually marked with high repeatability.

Assess the ergonomics, streamlined controls and software interfaces.

Review the availability of training and technical support for operators.

For projects that require mobility, compact and lightweight are favorable.

Stationary machines may be more appropriate for factory settings.

Heavy-duty materials typically lead to a longer service life of the machine.

Corrosion resistant finishes and other features enhance overall durability.

Assess the maintenance tasks to evaluate their frequency and complexity.

Evaluate how easily spare parts can be obtained.

Assess the upfront costs against operational savings in the long-run.

If applicable, include additional costs such as tooling or software updates.

By analyzing all these factors together, buyers will be able to select the most appropriate tube bender model ensuring that operational expectations and industry standards are met.

Manual Tube Benders vs Electric Benders

Since manual tube benders require human force to operate, they are cheaper and compact in size making them the primary choice for small scale operations and projects that need mobility. Their low precision makes them best for low complexity and low volume tasks. They are, however, low maintenance and versatile for many applications as long as advanced automation is not required.

Electric tube benders offer precision and increased efficiency with the ability to perform complex bends repeatedly. They are best suitable for high-output industrial environments where speed and accuracy is critical. The initial costs for electric tube benders is higher and so is the maintenance, but their long-term productivity offsets this increase in cost making them ideal for demanding applications.

It is important to assess the operational requirements, budgetary concerns, volume demands, and scalability before making a decision.

Each Area of Heavy Drawing Tube Bending

Tensile Strength: The tube material’s ability to resist deformation under tension influences the bending difficulty as well as the chance of cracking.

Ductility: Material ductility plays an important role. For example, less malleable materials such as steel or titanium are much more difficult to bend compared to aluminum or copper.

Wall Thickness: Walls with greater thickness improve the structural strength during the bend but also increase the amount of force that must be applied to achieve the bend.

Bending Radius: The least amount of bend radius possible should be considered in order to avoid failure or wrinkling of the material. Usually, tighter radii provide greater risk of cross-sectional deformation.

Bending Force: During the execution of a controlled deformation, fixed measuring machines with high force imply guarantee results with thicker and harder materials.

Control Precision: Unmatched control over intricate obligations is the CNC bend control machines offer.

Tool Compatibility: Is there a guarantee that tube dimension and material type calipers such tackle, rough measures of bend dies and mandrel tubes are fitted to fight the bar tool?

Batch Size: In the case of large-scale production, automated systems execute their obligations in a limited time, thus serving the company to cut labor costs.

Setup Time: Different tube specifications require machine adjustments. In this case, estimate the time needed to make the necessary adjustments.

Temperature Sensitivity: The operations at hand will affect the material changes of the alloy being bent if thermally sensitive parts are involved during the bending processes.

Corrosion Resistance: Does it require treatment after bending where used for some gaseous medium highly exposing the work to film forming salt percussive unguided blasting

Evaluation of the short-term and long-term costs considers machine acquisition, training, energy usage, and maintenance.

What Are the Benefits of Using a Hydraulic Pipe Bender?

The Efficiency in Metal Forming Projects

The use of hydraulic pipe benders increases the efficiency of metal fabrication projects by decreasing manual labor relative to other methods and increasing precision. Industry studies suggest that hydraulic benders can achieve bending speeds up to 30% faster than manual or mechanical benders—with some more complex bends taking longer. In addition, they provide consistent repeatability with tolerances usually around ±0.1°. Such precision reduces the expense of rework and, in conjunction with reduced waste, material costs.

Furthermore, hydraulic systems can manage a more significant range of pipe diameters and materials from lightweight aluminum to heavy-duty steel. For industrial applications, the hydraulic benders equipped for aluminum have bending capacity exceeding 2 inches in diameter. Energy-efficient models can reduce operational costs with advanced hydraulic systems designed to minimize fluid use while maintaining constant power output.

With working throughput and streamlined workflows, these contribute to the operational focus of long-term cost saving. With all these benefits increasing working throughput, streamlined workflows, and reduced fuel costs, it is no wonder hydraulic pipe benders are considered crucial tools.

Accuracy in Tube and Pipe Bending

Recent advancements in pipe bending technology, such as those present in modern hydraulic pipe benders, guarantee exceptional accuracy. These modern apparatuses achieve remarkable accuracy with a ±0.1° tolerance in angle of bend. Such accuracy is attained through the use of position digital controllers which are integrated with CNC (Computer Numerical Control) systems. CNC systems grant flexibility to the user by permitting complex multi-step bends to be performed with minimal error. For example, some advanced models allow 100 bend sequences to be programmed for a single setup thereby minimizing manual intervention and downtime.

The versatility of hydraulic benders is further showcased in other materials compatible data as most units can handle benders made of carbon steel, stainless steel, aluminum and even copper alloys. Load capacities for most hydraulic units range between 10 and 100 tons which means that these units can be used in both light duty and heavy-duty applications. Moreover, these hydraulic units are energy efficient as some models claim to cut power consumption by 20-30% while maintaining peak performance, thereby lowering operational costs.

Used in Automotive and HVAC Industries

Substantial advantages of energy efficient units includes reduced operational costs, reduction in consumption of energy and lowered environmental impact. Energy efficient models help industries reach set sustainability goals by claiming to consume 20-30% more power while still being able to perform at the same level with no additional strain on the machinery and resources. In addition to this, the wide range of compatible materials expands their applicability to the manufacturing sector, automotive and HVAC industries.

How to Maintain and Care for Your Bending Tool?

Pipe Bender Maintenance Tips

To keep a pipe bending tool operating properly and for a long time, it must be regularly lubricated. It would be wise to periodically apply machine-grade lubricants at intervals of 30 operating hours to the joints, bearings, and pivot points, as lubrication made on these components will result in reduced friction by 40%. Lubrication neglect, on the other hand, will wear-and-tear more rapidly, which has shown to reduce a tool’s lifespan by 25% on average.

Like many tools in different machinery operations, the bending tool has to be maintained on a regular basis in terms of calibration checks to guarantee precise work. Manufacturing many products to very precise metrics, like parts for aircrafts and cars, will be greatly affected by imperfections of only 1-2 degree in bending angle. It is best advised to calibrate every 500 cycles or every three months as long as the supplied calibration devices can measure with ±0.5 degrees.

Continuous monitoring of the dies and mandrels is the best way to have their optimal working conditions. Their changing performance metrics must be documented scrupulously using a detailed inspection log will keep track of the wear rates, replacement intervals, and dates, and overall performance data. Research has been done that replacing parts at 75% wear threshold will minimize equipment downtime significantly, close to 30%.

Frequent Problems and Possible Solutions

Primary Reason: Failure to calibrate correctly or misalignment of parts.

- Data Insight: An investigation on industrial machinery revealed that roughly 40% of uneven wear cases stem from equipment misalignment.

- Recommended Action: Schedule alignment verification to be performed every three months. Further, recalibrate the machinery serviced to specifications using laser alignment tools for greater accuracy as per manufacturer guidelines.

- Primary Reason: Unattended routine maintenance and component replacing before end-of-life.

- Data Insight: Predictive maintenance has been proven to cut break down associated downtimes by an average of 40%.

- Recommended Action: Install real-time monitoring systems to anticipate failures and schedule timely replacements integrated with sensors.

- Primary Reason: Blocked cooling systems or inadequate lubrication.

- Data Insight: Equipped components with adequate lubrication are reported to enjoy lifespan extension of up to 25%, per research documents.

- Recommended Action: Weekly inspections for airflow obstructions to cooling system components plus creation of operational cycle lubricating schedule.

- Primary Reason: Overspeed and use of inferior raw materials.

- Data Insight: Tools operated on speeds exceeding the set guidelines by upwards of 10% degrade 15% faster, aggravated sustained use.

- Recommended Action: Follow technical operation guides religiously and also ensure that materials used for tooling have set workload qualifications.

The combination of in-depth troubleshooting analysis and structured issue identification provided by the discussed methods above drastically improves equipment lifespan and efficiency.

Prolonging the Life of Your Tube Bending Equipment

The wearing of tube bending equipment is the result of a combination of factors: overheating due to lack of lubrication, excessive speeds of operation, materials not designed for the equipment in question. The following explanation is supported with data:

- Impact: Friction between components increases which increases the heat generated. Increases both the rate of part failure and overheating simultaneously.

- Data Insight: Research shows a 30% reduction operational lifespan of machinery with no lubrication.

- Impact: Premature weakening of mechanical parts due to stress becomes accelerated due to higher speed operation.

- Data Insight: A 15% increase of speed from the designed parameters increases the chance of mechanical failure by up to 40% with time.

- Impact: Suboptimal materials can result in non-conformity to operational specifications, resulting in excess tool wear and inconsistent bend radii.

- Data Insight: Nonconforming materials account for 25% increase in defect rate during a production cycle.

These causes and their actionable mitigation plans are proven through data. Observing lubrication schedules, not exceeding predetermined speeds, and using compatible materials all improve dependability and reduce required maintenance.

What Materials Can Be Bent with a Tubing Bender?

Common Queries Related To Tubing Benders

It is essential to have an understanding of the pertinent qualities of different materials while working with a tube bender to ensure that the bends are accurate and without any flaws. Reasons of specific materials with their characteristics for bending are provided below.

- Advantages: Less dense which makes it light-weight. Corrosion-resistant and relatively easy to bend as compared to other materials.

- Bending Considerations: Must be very carefully handled especially with regard to cracking with thinner walls of the tubes. A suitable mandrel should be used as well.

- Advantages: Has good durability, a high strength and is most commonly used in a number of industries.

- Bending Considerations: High carbon steel may need to be heated in order to avoid softening and deformation or fractures in steel. For stainless steel, bending needs to be done at a leisurely pace due to its rigid nature.

- Advantages: Has very good malleability and is also an excellent conductor making it useful for plumbing and HVAC purposes.

- Bending Considerations: Soft materials which are less difficult to bend, however very precise adjustments are a must.

- Advantages: Good look and aesthetics because of the finish and has always been a good resistant to corrosion.

- Bending Considerations: Can easily crack when put under stress and so must be bent carefully. May need to be annealed before bending.

- Advantages: Difficult to bend, but has a very good strength to weight ratio and is outstanding in resisting extreme environments.

- Bending Considerations: To achieve good quality bends, tackle under high control conditions with specific tools tailored to the job.

- Plastic (PVC, Nylon, Polyethylene)

- Advantages: Softer and more flexible than metal than tubing which can be used as an alternative.

- Bending Considerations: Must heat the area to be bent along with controlled cooling to avoid warping the tube.

Failure to acknowledge these specific characteristics while selecting the material will risk the optimum waste reduction along with optimizing bending operations.

How to Achieve Precision Bending

“Achieving precision in bending processes require setting of a variety of factors whose interactions are very complex.” All of the the following are crucial in achieving a certain and exact end:

Advanced tooling like mandrels or wipers is needed to prevent deformation for tighter bend radii.

In industrial processes, typical tolerance for angle and dimension is ±0.5° and ±0.1 mm respectively.

Greater force is needed for bending high yield strength materials like stainless steel.

Mild Steel: ~ 250 MPa Yield Strength

Stainless Steel: ~ 520 MPa Yield Strength

Elongation: The more the percentage, the lesser the risk of cracking during bends making it easier for sharp bends.

Aluminum 6061-T6: ~10% compared to ~40% for tempered copper.

Materials with a more active role in determining precision include various types of press brakes, rollers, and CNC mandrel benders.

CNC machines are known to have an estimated positional accuracy claiming not to exceed ±0.1 mm.

Uniform heating between 160-200°F is essential for some materials like PVC and Nylon to retain desired shapes while avoiding warping.

Blemishing can occur on the surface while overheating is known to weaken or compromise the surface.

Observing these factors helps the business operations achieve desired output metrics, optimized performance, and harness productivity per material used across several processes.

Assessing A Mini 90 Degree Tubing Bender’s Ability to Perform Heavy-Duty Tasks

To gauge the utmost capabilities of a Mini 90 Degree Tubing Bender, his specifications and features must be examined. Here is an outline:

Technical Features:

Compatible Materials: Aluminum, Copper, PVC, Steel, and Nylon tubing.

Maximum Diameter of Tubing: Between 1/4 inch and 3/4 inch.

Bend Radius: Minimum 1 inch depending on material and thickness of the tubing.

Dimensional Precision: ±0.1 mm.

Optimal Operating Temperature: 160-200°F, specifically for heat treated items like PVC and Nylon.

Performance Characteristics:

The ergonomics improve efficiency during sustained work, due to the ease of the bender’s grip.

Reduced fatigue caused by smooth lever action for the bender.

Effort Capacity:

Maximum performance not exceeding light to medium duty operations, usually under 10 tons of force.

Inefficient for high-grade industrial thick-walled tubing or super thick pipes.

Endurance:

Uses heat treated alloy steel which improves the lifespans against productivity wear and tear during heavy use.

Requires breaks when operated continuously under heavy-duty conditions.

Weight:

Ideal for repair work and installation due to low weight and compact dimensions.

Knowledge of the specifications enables users to ascertain whether or not the Mini 90 Degree Tubing Bender meets their project’s requirements, especially when dealing with precision and material restrictions.

Reference Sources

- Solving a new robust green cellular manufacturing problem with environmental issues under uncertainty using Benders decomposition

- Authors: Hossein Raoofpanah, V. Ghezavati, R. Tavakkoli-Moghaddam

- Published: 2018-09-25

- Journal: Engineering Optimization

- Summary: This paper proposes a new mathematical model for a cellular manufacturing system that incorporates environmental issues such as pollution and waste. The model addresses uncertainty in processing times and employs Benders decomposition to solve the problem. The study finds that demand significantly impacts cell formation costs and investigates the effects of green parameters on optimality.

- Methodology: The authors developed a robust optimization model and applied the Benders decomposition algorithm to solve it, analyzing the results through various scenarios to assess the impact of environmental considerations on manufacturing efficiency(Raoofpanah et al., 2018, pp. 1229–1250).

- Coordination of directional over-current relays in active distribution networks using generalized Benders decomposition

- Authors: H. Saberi, T. Amraee

- Published: 2017-06-29

- Journal: IET Generation Transmission & Distribution

- Summary: This study formulates the coordination of directional over-current relays (DOCRs) as a mixed-integer non-linear programming (MINLP) problem. The authors propose a two-stage analytical approach based on generalized Benders decomposition to optimize the settings of DOCRs while satisfying coordination constraints.

- Methodology: The approach involves solving a relaxed MINLP master problem in the first stage to determine current settings, followed by linear sub-problems in the second stage to ensure feasibility and optimality(Saberi & Amraee, 2017, pp. 4078–4086).

- Proximity Benders: a decomposition heuristic for stochastic programs

- Authors: N. Boland, M. Fischetti, M. Monaci, M. Savelsbergh

- Published: 2015-12-07

- Journal: Journal of Heuristics

- Summary: This paper investigates the use of proximity search as a tactical tool to enhance Benders decomposition for stochastic programming problems. The authors evaluate its performance as a heuristic on various instances, demonstrating its effectiveness in improving solution quality.

- Methodology: The study employs computational experiments to assess the heuristic’s performance against traditional Benders decomposition methods, focusing on its ability to handle stochastic elements in optimization problems(Boland et al., 2015, pp. 181–198).

Frequently Asked Questions (FAQs)

Q: What do I need to keep in mind when selecting a heavy duty pipe and tube bender?

A: Make sure to think about the material being bent, for example, if it’s going to be aluminum pipe or stainless steel pipe and tubing. Also, consider the diameter of the pipe and its thickness. You may also want to consider the bend radius and if you require a manual pipe bender or electric tube bender for easier use.

Q: How do I pick out the proper tools and apparatus for metal tube bending?

A: Think about what metal tube you will be using, for example, steel or copper. Manual level tube bender or pipe bending machine is required, consider what bends are necessary. Both depend for durability and accuracy precision on what type of metal fabrication project(s) you will be working on.

Q: How does a 180 degree tubing bender differ from a 90° bender?

A: Unlike the 90° bender that creates right angles, a 180 degree tubing bender creates complete U-shaped bends. The choice relies on what your project needs, whether it’s constructing roll cages or rigid conduits.

Q: Is it possible to use a manual pipe bender on stainless steel pipe and tubing?

A: Stainless steel tubing and piping can be bent with a manual pipe bender, however, considerable force is required. If you need to frequently complete this task, or for bulk processes, it’s more efficient to use an electrically powered or CNC pipe and tube bender.

Q: What is the benefit a pipe bender kit presents over other options for metalworking?

A: A pipe bender kit offers closure and flexibility since it comes with various attachments and dies to fit numerous sizes, shapes, and forms of pipes. This greatly aids numerous metal fabrication projects and minimizes the time needed to make adjustments by having one efficient tool.

Q: What is the importance of tube fabrication equipment in the creation of complex shapes?

A: Fabrication of tubes such as mandrel benders offer the needed intricacy to form complex shapes without collapsing the tube, particularly during single piece construction and reverse bend engineering. These machines also assure quality in production and uniformity in results.

Q: Which equipment is best suited for bending aluminum pipe?

A: With regard to bending an aluminum pipe, a manual lever tube bender or an electric pipe bender set for the softer aluminum would work well. Use of the correct equipment ensures that the pipe is bent without any cuts or deformation.

Q: In what ways is a mini 90 degree tubing bender helpful?

A: A mini 90 degree tubing bender is ideal for small projects and tight areas that would otherwise be inaccessible using larger equipment. It aids in accomplishing precise right angle bends which can be useful in detailed designs or in precise copper pipe bender uses.

Q: Why does a bender’s ability to handle a tube’s external dimension (OD) matter?

A: A bender’s ability to handle a tube’s external dimension (OD) matters because this dimension determines the size capacity of the bender. A bender’s capacity must be greater than or equal to the OD of the tube or pipe for bends to be made without hurting the material.

Q: What is the method of action of a plier-style bender in metal bending?

A: A plier-style bender governs metal processing through bending in that it has to be manually operated to achieve the desired angular displacement through leverage and force. It is best for light-duty tasks and provides control in applications where bending-such as in sheet metal work-need delicate adjustments.

- Materials You Should Never Laser Cut: A Guide to Safe Laser Processing

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide

- Pulsed vs Continuous Wave Lasers: What’s the Difference?

- Ultimate CNC Router Maintenance Checklist: Preventative Care for Machine Longevity