Regarding precision and durability, laser technology exemplifies a multifaceted tool for customizing products and materials. The buzz of two frequently used terms, laser marking and engraving, tends to overshadow their distinct differences. Although they have some things in common, they differ in particular ways, each offering unique advantages depending on the use. This article is intended to tackle the intricacies of laser marking and engraving comprehensively so that their distinct applications, benefits, and most affected industries are understood. As a manufacturer, entrepreneur, or even an everyday inquisitor looking for knowledge on sophisticated technologies, this guide empowers you with sound insights that will illuminate your intellect for decision-making.

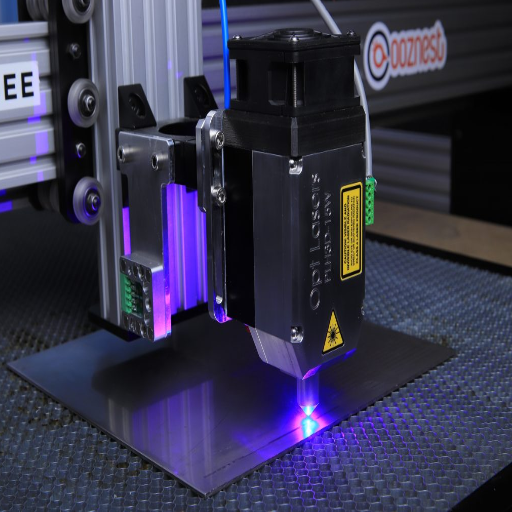

What is Laser Marking?

Laser marking is creating recognizable marks using a focused beam of light on the surface of the given material. Unlike engraving, marking does not remove any material; instead, it changes the surface to achieve marks through discoloration, oxidation, or other surface alteration. This method is also standard for placing logos, serial numbers, barcodes, or other identifying information on a manufactured item. Possessing great precision, laser marking is also long-lasting, non-contacting, and applicable to a broader array of materials, including metals, plastics, ceramics, and glass.

Understanding the Laser Marking Process

The laser marking process starts with choosing a laser suitable for the material and type of mark required. Fiber lasers are commonplace for metals, while CO2 lasers are perfect for non-metal materials like wood and plastic. After deciding the type of laser to utilize, the material to be marked is placed in a fixed position to avoid marking errors.

A laser beam is then focused on the material surface; its application of intense heat results in controlled modifications through physical changes or discoloration. Various techniques are employed depending on the frost requirements, like annealing on stainless steel, carbon migration on some alloys, and foaming on some plastics. Usually, the markings produced have great precision, often within microns of tolerances, which benefits many industries like automotive and electronics.

Compared to traditional techniques, laser marking has many benefits. Primarily, the non-contact nature of laser marking eliminates any possible wear and tear on the material. The speed at which the marker works also distinguishes this technique. Certain systems can mark thousands of items per hour, which is beneficial for industrial-scale production. Under optimal conditions, modern laser marking technology reports speeds above 2,000 characters per second.

The strength of laser markings makes them readable even in very high temperatures, chemical exposure, abrasions, and other harsh conditions. Thus, laser marking is popular in industries such as aerospace and medicine, which demand strict compliance with regulations and high standards. For instance, laser marking ensures efficient supply chain management and counterfeit evasion by manufacturing parts with distinct serial numbers or barcodes.

Types of Laser Marking Machines

Every laser marking machine is custom-made to suit a specific need or application. Below are the more commonly known machines, along with their uses and characteristics:

- 1. Fiber Laser Marking Machines

Marking machines using fiber lasers are well known for their high-speed marking and precision. They are best suited for marking metals such as aluminum and steel and certain types of plastics. These machines require very little maintenance, have an efficient operational life, and run for an astonishing amount of time, over 100,000 hours. Fiber lasers are industrially used to manufacture medical tools, automotive parts, electronics, and other such goods.

- 2. CO2 Laser Marking Machines

The devices are best used on wooden, leather, glass, acrylic, and paper markings. CO2 is the glass used in the laser these machines work on. CO2 laser marking machines are economical and multi-purpose, making them suitable for use in several sectors like packaging, signage production, and the textile industry.

- 3. UV Laser Marking Machines

Tools that apply UV laser technology use intense UV light to mark glass, ceramics, and plastics. They claim some effect on select types of metals, too. Lower energy levels imply that a laser burn does not destroy adjacent areas and is helpful for tasks that demand exceptional precision, such as the etch marking of medical devices, packaging, and pharmaceuticals.

- 4. Green Laser Marking Machines

Green laser marking machines can mark metals like gold, silver, and copper due to their reflective properties and 532nm wavelength. These machines also work well on non-metallics, such as plastics, where sharp contrast is essential. Their impeccable accuracy makes them the most popularly used laser markers in goldsmiths, manufacturers of electronic components, and even the solar photovoltaic industry.

- 5. MOPA Laser Marking Machines

MOPA laser marking machines (master oscillator power amplifier) offer increasing freedom in choosing particular parameters like pulse width, which leads to enhanced color contrast effects, especially in stainless steel. They are frequently employed for richly engraved and highly decorated or bold, colorful designs and markings, making them useful in manufacturing high-end products and electronics.

- Data on Market Performance and Trends

The steady expansion of the global laser marking machine market is being observed owing to new manufacturing technologies and greater demand throughout different industries. As per recent business reports, the market is expected to increase at a compound annual growth rate (CAGR) of approximately 7.1% from 2023 to 2030. These machines are also upgrading with the addition of automated processes and IoT integration, improving their performance and efficiency across different industries even further.

Applications of Laser Marking in Various Industries

Laser marking across multiple industries stems from its precision and speed. It is beneficial for adding serial and QR codes, which require minimal space and are highly sensitive to microchips, PCBs, and other delicate components. Laser marking has completely altered operations in the automobile and electronics industries.

- Automotive Industry

The automobile industry requires precise traceability of components within an automobile. Engine parts, safety components, and even chassis numbers require constant monitoring and marking to ensure compliance with quality control and industry standards. Durability and clarity are necessary for most markings, especially for harsh conditions like extreme Hertz or abrasion, which are present in the automobile industry. Scan range and error reduction have improved drastically.

- Electronics Industry

Microscopic and integrated circuitry have been rising, slowly expanding the electronics industry. New methods of marking delicate and smaller components, like laser marking, have emerged. Today, PCBs, microchips, and connectors are marked and tagged using QR codes and serial numbers. These sensitive devices require daily handling while simultaneously ensuring high clarity and durability standards for optimal performance, which is achieved through the help of laser beating.

- Medical Industry

Laser marking has essential applications in the medical field, particularly for sutures, implants, and other surgical instruments. Due to strict rules such as the Unique Device Identification (UDI) system, manufacturers use laser marking for traceable compliance. The marks made are biocompatible and corrosion-resistant, which is ideal for devices routinely subjected to sterilization. This reduces risks associated with counterfeit products and ensures patient safety.

- Aerospace Industry

The aerospace sector requires identification methods for its sophisticated, highly resistant, and long-lasting parts. Laser marking is used to etch tracking details, barcodes, and even part numbers on titanium and other composite alloy materials. Due to the harsh environments, including high altitudes and a wide range of temperatures, precision, and fortitude are crucial to the industry.

- Consumer Goods

Laser personalization and branding continue to grow in the consumer goods market for home appliances, jewelry, and even packaging. Laser marking helps mark logos or text onto these goods and patterns. By improving product appeal, higher-durable finishing enhances customer satisfaction. Furthermore, laser marking helps improve sustainable practices as ink-based printing materials are minimized.

- Food and Beverage Industry

In the food and beverage sector, laser marking technology is now used for packaging purposes. It is used for the direct marking of die products’ expiration dates, batch numbers, and other traceability information without contaminating the packaging. This approach eliminates the use of traditional labels, making it more eco-friendly by reducing waste or overdependence on ink and stickers, inks, and other consumable materials, unlike conventional labeling approaches.

- Industrial Manufacturing

In addition to food and beverages, the general laser engraving industry is now incorporating laser marking into inventory management and equipment monitoring for tools and machinery. Further automation of the engraving process increases production throughput, improves workflow consistency, and improves output quality. Reports contend that laser engraving is aiding in reducing downtime in production lines through enhanced operational efficiency.

The use of lasers in marking these industries allows businesses to achieve more reliability, improved traceability, and improved flexibility while observing strict regulatory policies. This technology will continue to shift the focus towards the use of advanced precision laser systems for wider application in these diverse industries.

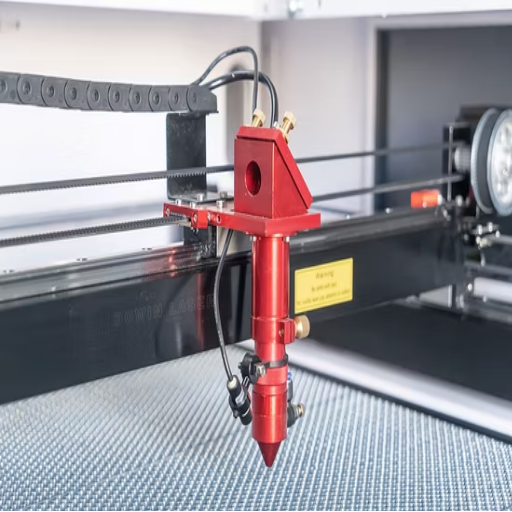

How Does Laser Engraving Work?

Laser engraving employs a specialized beam of light to etch or mark an object by removing material from its surface. This is done using laser industrial machines that create intense heat, which vaporizes the material on the object step-wise, called engraving. With the use of top-grade software for laser guiding, the movement of the laser is controlled with extreme precision so that accurate detail engraving is achieved. It is a swift, advanced, dynamic way of engraving that can be used on numerous materials such as wood, glass, plastic, and metal.

Overview of the Laser Engraving Process

While many people are working at their computers, they never envision that modern technology has enabled them to create stunning artwork that can be used in advertising, promotions, awards, jewelry, or gifts. For example, let us consider laser engraving technology with a computer-controlled laser engraver. The engraving process has become simple due to the integration of computer art and modern machinery. The process starts when a computer draft or drawing is created and transferred to high-end software.

The piece of work being engraved is kept in a position where a beam of light is at a center–frame position. The light produces heat that intensifies to between 20°C and 20,000° C. The engraving machine is set with parameters that control the beam light every 0.001 inch and 0.020 inch. This allows precise measurements to be marked with a laser that shaves off material and grants stunning circular marks.

Controlled computer devices and laser carving machines are gadgets used in other fields of design and molding technology. They have become more advanced and also speedier over time. The efficiency of industrial and commercial-grade machines is up to 120 inches per second. Both academic and business fields can apply such technology when creating stainless cases and parts for other items targeted towards people looking for jewelry that can be ordered from various places and also aid in delicate custom items. Moreover, such technology is heavily helpful in industries ranging from crafting goods to jewels, enabling engraving and molding.

The use of lasers also has extraordinary environmental advantages. In comparison to other methods, laser engraving does not require contact or the use of chemicals, which greatly reduces waste and minimizes tool damage. According to certain studies, eco-friendly laser systems focusing on optimized energy use can conserve up to 30% more energy than conventional engraving methods.

Modern technological advancements, such as the development of AI, have made the job of a laser engraver easier through automation. Automating these processes enhances workflow efficiency by improving scale customization and streamlining design processes. Coupled with achieving vertical resolutions of roughly 1000 dpi, laser engraving remains the top choice in a breadth of fields for work that demands meticulous attention to detail.

Difference Between Laser Engraving and Laser Etching

These two processes differ in that laser engraving refers to marking a material by shredding its surface using laser beams, while etching flushes out parts of the material and adds more to the surface artwork.

If you look closely, you will notice that although both processes come close in their definitions, they vastly differ in practicality. High-powered lasers are used to cut and split the surface of a material. This destruction leads to the forming of deep texts that are hard to erase and serve essential functions like identifiers, barcodes, or logos. Bottom line… Even though engraving and obliterating metals, glass, wood, and certain plastics may be difficult, doing it with precision is possible. As a rule of thumb, the higher the laser’s intensity, the greater the engraving power – 0.02-inch deep markings are the smallest return one can expect.

Unlike engraving, laser etching does not change a material’s surface levels but transforms it slightly. As an example of the difference, while engraving on a surface lowers the surface, etching will add a skinny layer that reaches a max of 0.005 inches in height. It is worth noting that although etching is inefficient for metals and ceramics, it works best for softer alloys like aluminum or processed surfaces like anodized coatings. Given these conditions, etching becomes a go-to option for branding and decorative designs or just about anything with high contrast but requires little depth.

In terms of operational performance, laser engraving usually requires more power and time to complete than etching. On the other hand, engraving is more resistant to wear and is more suitable for industrial and outdoor use. Etching is faster and more energy efficient, especially for detailed artistic work or lighter projects.

There is a great deal of diffraction between these methods, and the selection of tattooing or engraving a laser will depend mostly on the use, material, and outcome. Both methods, whether for resistance or aesthetic beauty, are of great importance to fields like manufacturing, healthcare, and appliances.

What are the Differences Between Laser Marking and Laser Engraving?

The differences between laser marking and engraving stem from the two’s depth and technique. In laser marking, a flat and precise mark is produced by discoloring or oxidizing the material without any material removal, unlike in engraving, which extracts material from the surface and results in a deep groove. While engraving is better for text or designs that require durability, marking allows for detailed, high-contrast, and permanent marks ideal for barcodes, serial numbers, or logos. The aesthetics, alongside their intended use, determine which technique is chosen.

Comparing Laser Marking vs Laser Engraving Techniques

- Significant Distinctions in Applications and Marking Permanence

In the case of laser engraving and marking, examining their functions and the endurance of the resulting marks stands out as crucial. Regarding laser marking, its application can be seen within the electronics, medical devices, and automotive industries, where precision and readability are paramount. For example, laser marking is routinely used to produce identification markings such as serial numbers and QR codes owing to its capacity to mark metals plastics, and ceramics with excellent contrast and resolution. It performs best when aesthetics and minimal alteration to the materials are critical.

In contrast, laser engraving is more popular for use in aerospace, jewelry, and industrial tooling for engraving that requires deep and long-lasting marks. Engraved designs or text are made with a laser, and as a result, they are tough to wear out, fade, or corrode, even in harsh circumstances. This approach is beneficial for manufacturing resilient machine components such as branded tools and custom signage.

- Comparing Speed and Depth in Processing

The speed of laser marking and engraving depends on the particular circumstances. As in laser marking, altering the surface requires significantly less time than removal processes like engraving. For instance, fiber laser markers can exceed 7,000 mm/s, which is very advantageous for large-scale productions. On the other hand, engraving lasers usually take more time because of the deeper cuts. Studies indicate that engraving can be anywhere between 0.02 mm and several millimeters, depending on the power and type of laser used.

- Material Suitability Evaluation

Although these two options are flexible in application, the selection of materials is equally important. Laser marking generates an extremely marked surface on coated metals, anodized aluminum, and some plastics, while engraving exhibits great variation in adaptability. Engraving is often done on more resilient materials such as stainless steel, titanium, and wood. The prominence of the marks means that engravings will be maintained in many different objects and conditions.

- Cost and Efficiency Considerations

Cost factors may determine the choice between the two techniques. Due to speed and low impact on materials, laser marking systems are cheaper and more economical for high-volume production. Conversely, laser engraving equipment tends to be more expensive but offers long-term value for applications that require high durability. Efficiency requires balancing production factors and specific needs.

- Depth and Detail: Engraving vs Marking

With depth and detail in mind, I would say the application drives the decision. When I need a design that is described as detailed and permanently carved into the material, laser engraving does that best. Laser marking is preferred for marks on the surface that need to be done at high speed, with pinpoint accuracy, and low cost, especially when the quantity is large. It would always depend on the project’s specifications to make such decisions.

Materials Suitable for Laser Marking and Engraving

Etching or marking using a laser can be done on an extensive list of materials. Some of the most common, due to their strength and precision in holding marks, include metals like stainless steel, brass, aluminum, and titanium. Stainless steel marks are frequently utilized in the medical and aerospace industries as they are incredibly detailed yet corrosion-resistant.

Plastics are also a popular choice for laser marking, especially in the automotive and electronics industries. Laser marking techniques like CO2 or fiber laser marking are well suited for the production of stamps, industrial labels, bar codes, and logos because of the high resolution and speed they offer. Moreover, ABS and polycarbonate plastics are great at creating contrast, which makes them excellent for Laser marking.

Wood and leather are two commonly used materials for aesthetic purposes in crafts and personalization goods. Engraved wood attains a smooth finish, further enhanced with the intricate leather designs often created in the fashion and accessory industries.

Laser engraving provides glass and ceramics with an accurate decorative touch while maintaining the integrity of the surface. These techniques are frequently used to customize glassware, tiles, and trophies.

Furthermore, lasers can be utilized on coated materials, such as anodized aluminum, achieving precise and high-definition marks that stand out from the underlying material. This capability is now crucial for purposes like part identification and product branding.

The precision of laser marking and engraving on various materials is essential in manufacturing and custom-tailoring. The technology guarantees efficiency and quality in the end product, demonstrating its crucial role in the industry.

When should you use laser marking vs. laser engraving?

Laser marking is best for clear, distinct, lasting marks such as logos, barcodes, or serial numbers that do not need to be cut deep into the material. This makes it ideal for product branding and compliance labeling, where aesthetic appeal and legibility matter most.

Laser engraving is better suited for objectives requiring depth and added durability. It enhances an object’s aesthetic appeal by creating deep and tactile marks ideal for industrial applications with repetitive use, such as mechanical parts and tool identification.

Both depend on the desired purpose of the mark, the material to be used, and the depth to be achieved.

Choosing the Right Process for Your Project

It is crucial to contemplate material type, production volume, and marking impact factors to make the optimal decision for your marking requirements. As an illustration, research demonstrates that laser engraving is particularly useful for metals, glass, and some plastics because of their markers’ accuracy and permanence. Inversely, delicate surfaces or high-speed production lines prefer laser marking because it is more forgiving on the material’s surface.

Studies suggest a laser marking system can reach the staggering acceleration of 7000mm/s, making it the more advantageous option for mass production settings. Furthermore, laser engraving outperforms in-depth durability, with metal engraving depths often achieving 500 microns, ensuring marks withstand harsh conditions.

Social responsibility also impacts these technologies’ environmental sustainability. Lower energy levels and the absence of inks or hazardous chemicals make laser marking more sustainable. When looking at solutions, this is a significant factor for laser marking that some industries may want to prioritize.

In taking steps toward balancing precision and endurance or production efficiency, select a process that aligns with the project objectives to ensure that the set goals are achieved.

Factors Influencing the Decision: Cost, Time, and Material

- Cost

The price of the marking process is always considered first in decision-making. The harsh marking systems have a more expensive initial purchase price than the traditional methods but offer savings in the long run due to the absence of consumables such as ink or chemicals. In contrast, the chemical and ink-based marking methods have a low initial purchase price, but ongoing expenditures on materials and maintenance can offset this advantage.

- Time

Time efficiency is key during high production turnover time windows. Compared to laser marking, other methods take longer and are inferior in marking advanced complex patterns or intricate designs. Marking Ink is time-consuming for drying and increases the time spent on maintenance or refilling consumables, leading to more downtime, which further halts the production line.

- Material

The versatility of the marking method’s compatibility with various materials is essential. Lasers are very versatile in terms of their materials, including metals, plastics, ceramics, and glass. Notably, chemical or ink-based methods may have specific materials that could react poorly to the chemicals or inks used or be unable to hold the ink convincingly. Evaluating a material’s durability, considering the intended use of the item, is vital to make a good choice.

Can Laser Technology Be Used for Both Marking and Engraving?

Indeed, laser technology can be used for marking and engraving, and it offers different applications in various industries. Even though both processes employ laser beams, their purposes and impacts differ. In laser marking, information is added as a clear and readable mark while ensuring that the material’s structure is not altered, characteristic of surface laser processes like engraving. This technique is commonly employed for branding, serial numbers, barcodes, and other identifiers due to its permanence, high-contrast visibility, and resistance to fading or wear over time.

In contrast, laser engraving means creating designs, text or patterns by removing some material in depth. This method gives the desired touch of raised engravings that are highly durable and can withstand harsh conditions. For example, in the automotive industry, laser engraving is preferred for marking permanent labels on engine parts.

Laser technology has recently improved various processes’ speed, accuracy, and efficiency. For example, marking and engraving on metals and plastics have sharply risen in popularity due to powerful and efficient fiber lasers. Industry estimates suggest that fiber lasers can accurately mark metals at speeds close to 7,000 millimeters per second. Laser marking tools have seen significant growth in demand, with projections estimating the laser processing industry will surpass $25 billion by 2027, showcasing increased industrial use of the technology.

Companies may adjust the type and power of the laser used to set one machine for both marking and engraving, which enhances versatility while lowering costs. Regardless of the benefits, the specific application and the properties of the material in question are still fundamental concerns when choosing marking or engraving.

Understanding Laser Machines Capabilities

The efficiency and precision of laser machines have advanced tremendously, especially across multidisciplinary industries. The latest enhancements feature multi-axis motion systems and high-speed galvo heads, allowing further processing speed increases without sacrificing quality. Market analysis shows that fiber lasers account for approximately 50% of the global laser processing market due to their adaptability and strength, particularly regarding metal. Moreover, CO2 and diode lasers still cut, engrave and mark non-metal materials such as acrylic, wood, and glass, which are crucial for the industry.

The developments in Artificial Intelligence and software automation have also shown their worth. Current laser systems come with tailored software for complex designs, including optimization on the micrometer level. Some laser systems used for PCB manufacturing require ultra-fine detail, which can go down to 10 microns. Also, the latest laser machines have millennial-worth of energy efficiency improvements, some of them cutting the power needed by over 30%, which helps meet manufacturing sustainability objectives.

After thorough analysis, reports from the industry highlight that small enterprises and hobbyists show increased interest in portable and compact laser systems. Due to these advancements, laser machines continue augmenting their capabilities to provide unparalleled accuracy, versatility, and scalability for various applications.

Fiber Laser vs CO2 Laser: Which is Better for Marking and Engraving?

Choosing between fiber and CO2 lasers for marking and engraving purposes primarily depends on the material used and the intended results. Fiber lasers are preferred when dealing with marks on stainless steel, aluminum, brass, and some plastics. Their beam intensity is sufficiently high, and their shorter wavelength of 1064 nm allows for engraving on hard surfaces. Additionally, the durability of fiber lasers is well-known since they last up to 100,000 operational hours and require less maintenance due to the lack of moving parts.

CO2 lasers, on the other hand, are more effective on non-metallic materials such as wood, acrylic, glass, fabric,s and paper. They operate at a higher wavelength of 10,600 nm, allowing them to cut thicker materials. This capability offers greater versatility than Fiber lasers in non-metal engraving and cutting applications. Nevertheless, CO2 lasers still fall short in lifespan and require more maintenance than fiber lasers.

Cost difference is one of the most significant distinguishing factors between the two lasers. Fiber lasers are generally more expensive initially but more durable and energy-efficient, which translates to tremendous savings. On the other hand, though CO2 lasers are cheaper and more accessible, their maintenance and energy expenses can be pretty costly. This clearly illustrates how the CO2 laser is the better option for small businesses or hobbyists looking to work with non-metals. For those in the industry dealing with high-precision work of metals, the overwhelming preference for fiber lasers is evident as they offer unrivaled performance with lower operating costs.

As seen in the example, one can figure out which laser system best suits one’s needs by focusing on material, production volume, budget, and application requirements.

Reference Sources

-

“An Overview Study on Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry”1:

- Key Findings: This study highlights the versatility of laser technology in manufacturing, emphasizing its precision in cutting, engraving, and marking. It discusses the advantages of laser engraving for creating intricate designs and reducing production time and costs.

- Methodology: The paper provides an overview of laser applications, focusing on the principles of laser operation and its integration into Industry 4.0.

-

“The Effect of Etchant Concentration on Surface Morphology of Porous GaP Produced by Laser-Induced Etching”2:

- Key Findings: This research explores laser-induced etching to create nanostructures, which could be relevant for advanced marking and engraving applications.

- Methodology: The study uses laser-induced etching to analyze surface morphology changes under varying etchant concentrations.

-

“Laser Marking as Environment Technology”3:

- Key Findings: This paper focuses on the environmental benefits of laser marking, such as reduced waste compared to traditional methods. It also examines how different laser parameters (e.g., pulse frequency, energy) affect surface texture and color changes.

- Methodology: Experiments were conducted using the TruMark 6020 laser marking machine, with surface analysis performed via scanning electron microscopy (SEM) and roughness measurements.

- Top Handheld Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between laser etching vs laser engraving?

A: The main difference between laser etching and laser engraving lies in the depth of the material affected. Laser engraving involves a deeper penetration of the laser beam into the material, while laser etching creates a shallow mark on the surface.

Q: Do I need a laser for laser etching and laser engraving?

A: Yes, both laser etching and laser engraving require a laser. A laser engraving machine or laser marker uses a focused beam of light to alter the material’s surface.

Q: What is the laser etching process?

A: The laser etching process involves using a laser beam that heats the material’s surface, causing it to vaporize and create a mark. This process is often used to create designs or text on various surfaces.

Q: What industries use laser etching?

A: Many industries use laser etching, including manufacturing, jewelry, electronics, and signage. Laser etching is often used for branding, product identification, and customization.

Q: How does a laser engraving machine work?

A: A laser engraving machine uses a high-powered laser beam to create a design or text that penetrates the material. The laser beam is pulsed to achieve the desired depth and detail in the engraving.

Q: What is the difference between laser engraving and etching?

A: Laser engraving typically results in a deeper mark than etching. While engraving removes material to create a cavity, etching alters the surface appearance without significant material removal.

Q: Can laser etching and engraving be used interchangeably?

A: While the terms are often interchangeable, they refer to different processes. Laser etching creates a shallow mark, while laser engraving involves deeper material removal.

Q: What is the main difference between laser etching and laser engraving regarding results?

A: The key differences between laser etching and laser engraving are the depth of the mark and the visual effects created. Laser engraving produces a more pronounced and durable mark, while laser etching results in a more subtle surface change.

Q: What is laser dark marking?

A: Laser dark marking is a technique used in laser engraving that creates a darkened area on the material’s surface without removing significant material. This method is often favored for its aesthetic appeal and durability.

Q: What materials can be used with laser etching machines?

A: Laser etching machines can work with various materials, including wood, glass, metal, plastic, and ceramics. The choice of material often depends on the desired outcome and the project’s specific requirements.

- Common Types of Laser Marking: A Guide

- Laser Rust Removal: Pulse Laser Cleaner for Rust, Oxidation & More

- Solve Power Drop Issues in Fiber Laser Cutting Machines: Discover Effective Solutions

- Unlocking the Secrets of UV Laser Marking Machines: How Does It Work?

- Understanding How Laser Marking Machines Work: A Complete Guide to Laser Marking Technology

- Unlocking the Potential: How to Use a Laser Marking Machine for Engraving and Etching

- Laser Dental Cleaning vs Traditional Methods: Revolutionizing Dentistry with Laser Teeth Cleaning

- Understanding Speed in Laser Marking: How to Optimize Your Laser Marking Machine