When it comes to working with metals like aluminum and sheet metal, laser cutting is one of the more precise and efficient techniques of shaping materials since it incorporates technology which allows for diverse applications. The purpose of this blog is to discuss laser cut aluminum and sheet metal in detail along with their properties, how products benefit from laser cutting, and what industries use them. For a manufacturer or engineer, or anyone fascinated with contemporary fabrication approaches, this article will illuminate the importance of laser cutting and its many possibilities in transforming metalworking projects into reality.

What is Aluminium Laser Cutting?

Aluminium laser cutting is a form of fabrication that utilizes focused laser beams to either cut or engrave aluminum sheets with remarkable acuity. This process uses intense light to either melt, burn, or vaporize specific parts of a material to create clean edges and elaborate designs. Laser cutting is distinguished by rapid speed, precision, and minimal material wastage and is therefore popular in the aerospace, automotive, and electronics industries that require high-quality customized parts made of aluminum.

Understanding Laser Cut Technology

The efficiency of laser cutting technology is particularly valuable when dealing with the precise manufacturing of aluminum components. This technique surpasses expectations in accuracy with tolerances as tight as ±0.001 inches, eliminating the need for finishing touches e.g. secondary refinement. The speed of the cutting process is yet another area of advantage; modern fiber lasers are capable of achieving cutting speeds of 1,200 inches per minute on thin aluminum sheets, shortening production time immensely.

Additionally, the decreased kerf width – in some cases, as small as 0.004 inches – improves material efficiency because it permits tighter nesting of parts, thus reducing scrap. It also employs non-contact cutting, which avoids any mechanical stress on the aluminum sheets, keeping the structure intact. In addition, laser cutting systems are usually equipped with automated control software for consistent output, especially for mass production.

Observation from various industry sectors suggests laser cutting eliminates up to 30% more material compared to traditional techniques such as mechanical shearing and punching. These aspects amplify the need for precise, cost-sensitive industries that laser technologies fulfill with increasing efficiency and quality.

The Implementations of Fiber Laser in Cutting Aluminum

Fiber lasers have brought a new level of precision, efficiency, and material use into aluminum cutting. Here are some of the numbers and specifics regarding its advantages:

- When cutting thin aluminum sheets, fiber lasers can operate at speeds up to three times faster than CO2 lasers, a clear mark of enhanced operational efficiency.

- In contrast to CO2 lasers, which function at an average of 10-15%, fiber lasers operate at an energy efficiency rate of roughly 35%.

- Aluminum sheets can be cut between 0.5mm to over 30mm depending on the machine’s power output.

- Simpler laser systems incur 40 to 50 percent higher maintenance costs than fiber lasers, which boast a simple design and solid state with very few moving components.

- Operations that require post-processing are minimized through burr-free, clean cutting with reduced heat affected zones utilizing fiber lasers.

- QoA is consistent when integrating fiber lasers with CNC systems, and due to the lack of manual intervention required, they may be deployed in automated high-volume production lines.

- Increased resource output and decreased material waste is possible due to optimized beam focus enabling minimal kerf width cutting.

The lasers precision enabled fiber lasers to be widely adopted in aerospace, automotive and electronics industries where performance is crucial.

Uses of Aluminum Lasers

Laser cutting is recognized as one of the most efficient methods of working with aluminum and for good reason. It provides an accuracy of ±0.001 inches which surpasses other methods. Such precision is vital in the aerospace industry, where every aspect is a matter of safety and performance.

With modern fiber laser systems, the cutting speed possibilities reach up to 1200 inches per minute (IPM). For example, an aluminum 1/8 sheet can be processed with over 1000 IPM, reducing the manufacturing time drastically in comparison to other traditional methods like mechanical saws.

Moreover, fiber lasers also show an incredible energy efficiency, with the power conversion to spendable energy being in the order of 30-40%, making the operational fibers substantially lower. The HAZ areas are small where the distortion caused by the heat is minimized, maintaining the structure of the aluminum.

The precision and metrics provided above laser cutting methods constitute the performance of industrial manufacturing and its depth, necessity in modern industrial manufacturing is reinforced.

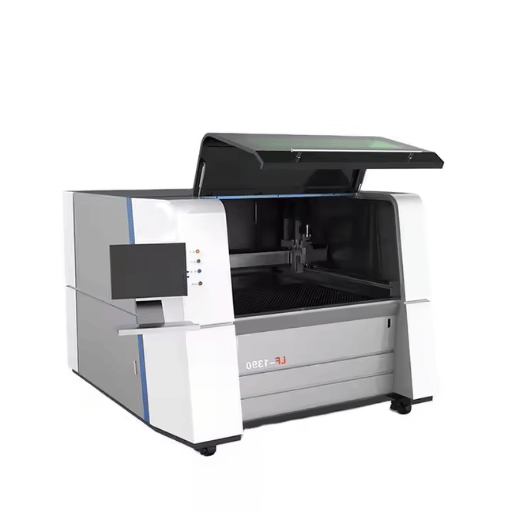

How Does a Laser Cutting Machine Work?

Understanding The Cutting Process

Laser cutting machines or Laser cutters, use focused, high-powered laser beams to cut the surface of a material by melting, burning or vaporizing it. There are three key steps necessarily involved in cutting: Firstly, a concentrated beam is generated by the laser. Secondly, the beam is aimed and focused through a lens onto the material, and lastly, a powerful pressurized assist gas is used to drive away the barged material. Achieving clean cuts with minimal waste.

Different Technologies of Laser Cutters

Laser cutters are different based on the type of laser source they make use of and these differ based on application and type of material. The following are the three main technologies:

CO₂ lasers are gas lasers that use a mixture of carbon dioxide, nitrogen, and helium as the active medium.

These lasers are highly effective for cutting, engraving, and marking non-metallic materials such as wood, acrylic, plastics, and textiles in industrial fabrication.

Type of laser: gas

Wavelength: ~10.6 μm

Power range: 30W to several kW

Applications: industrial fabrication, signage, and artistic designs.

Fiber lasers use a seed laser amplified within optical fibers and are also classified as solid-state lasers. These types have high beam equalty which makes it ideal and enhances its efficiency in metal cutting and marking.

Type of laser: solid

Wavelength: ~1.06 μm

Power range: 20W to 10kW and beyond:

Applications: cutting metal sheets, precise engravings, and aerospace manufacturing.

Nd:YAG lasers use neodymium-doped yttrium aluminum garnet and are also classified as solid-state. These lasers are best suitable for tasks requiring high energy density, like deep cutting and welding. They work better in both pulsed and continuous modes

Type of laser: solid

Wavelength: 1.064 μm

Power Range: 50W to several kW

Applications: heavy-duty manufacturing, dental tools, and medical device production.

Depending on the material and accuracy needed, each of these laser cutter technologies provide different benefits; hence, it is important to choose the appropriate one to achieve optimal results in various industries.

Significance of Laser Beam in cutting Metal

The distinct aspects of laser beams, their accuracy, efficiency, and versatility make them irreplaceable with regards to metal cutting. Laser beams incinerate, melt, or vaporize the material due to its highly focused energy. As a result, releases clean and high quality cuts while ensuring minimal distortion. Unlike other cutting methods, lasers are unparalleled in precision, especially when it comes to thin and delicate patterns or fabrics. Moreover, precision lasers repeatable to aerospace and defense industries have been able to improve the power output of the laser, changing the wavelength and subsequently increasing the cutting speed and range of metals, even reflective and heat sensitive alloys. This type of engineered accuracy makes laser cutting vital for the aerospace, automobile, and medical device manufacturing industries.

What Materials Can You Laser Cut?

Common Aluminum Alloys for Laser Cutting

The thermal and reflective properties of aluminum alloys make the laser cutting process highly efficient. Below is a list of some common aluminum alloys along with their properties that are used in laser cutting.

- Key Features: Remarkable corrosion resistance, high fatigue strength, good weldability.

- Applications: Marine parts, fuel cells, and aerospace components.

- Typical Thickness for Laser Cutting: 0.02″ – 0.25″ (0.5 mm – 6.35 mm).

- Key Features: High strength to weight ration, good machinability, and thermal conductivity.

- Applications: Structural parts, automotive components, and manufacturing machines.

- Typical Thickness for Laser Cutting: 0.04″ – 0.50″ (1mm – 12.7mm).

- Key Features: Light weight with superior strength, good wear resistance.

- Applications: Aerospace engineering, military equipment, and motorsports.

- Typical Thickness for Laser Cutting: 0.02″ – 0.125″ (0.5 mm – 3.18 mm).

Although aluminum reflects most light, laser processing can be difficult. Today’s lasers that feature anti-reflective coatings, along with other optimized beam characteristics, have greatly increased cutting effectiveness. Fiber lasers can cut aluminum alloys more effectively than other lasers because of their shorter wavelengths and ability to produce higher energy densities. This advancement results in better edge quality, lower heat damage, less time needed for work, and faster fall time than the older CO₂ laser systems.

These advancements highlight how important choosing the right materials combined with adapted laser technologies are when cutting aluminum alloys.

Comparing Aluminium Alloys and Sheet Metal

Aluminium alloys and sheet metal should be compared in the context of their advantages, properties, applications, and uses across various industries. Here is a thorough summary:

Aluminum Alloys:

They are lightweight and have a high strength-to-weight ratio

They have high corrosion resistance even in some of the most hostile environments.

They have excellent thermal and electrical conductivity.

They can be welded and fabricated easily.

Sheet Metal:

They are versatile and obtained from different materials such as aluminum, steel and stainless steel.

They have a consistent thickness which is important for precision applications.

They have high tensile strength depending on the material type.

They can be machined with ease into complicated shapes.

Aluminum Alloys:

The Aerospace industry utilizes aluminum alloys for the frames and other components of the aircrafts.

The Automotive Industry also uses aluminum alloys in structural components and body panels.

They are used in electronics for heat sinks and housings.

Construction uses them for window frames and roofing.

Sheet Metal:

used in Manufacturing of enclosures for electronic devices and machinery.

used as building facades and for ductwork and roofing.

used for automotive structural parts and panels.

used in Custom fabrication for industrial equipment.

Aluminum Alloys:

They have better corrosion resistance compared to most sheet metals.

They are lightweight which reduces transportation and fuel expenses.

They have a high recyclability and sustainability rate.

Sheet Metal:

They are lower in cost compared to aluminum alloys and easily accessible in bulk quantities.

The flexibility to choose from different metals for specific application needs.

They can be easily tailored to engineering solutions.

These insights shed light on the need to consider the particular demands of a project to establish whether its requirements call for the use of aluminum alloys, sheet metal, or a suitable combination of both.

Aluminum Sheet Cutting Challenges

Aluminum sheet cutting is accompanied by some technical difficulties presented below that require meticulous attention, detailed planning, and specialized tools to execute properly:

- Cutting Edge Heat: Each mettalic material has its own composition, so aluminum is one of those metals which has a reliable conductor , thus rising temperature at the cutting edges is inevitable. This effect can cause wear of rotary tools or thermal softening of material which would adversely that would also make it unable to achieve a desired quality. According to research, inadequate cooling measures can cause excess tool cooling temperature by around 30% which makes the cutting process much less efficient.

- Tool Wear: Sectors of the motor are made from aluminum because it is that shows high ductility and his ability to stick to cutting tools, and therefore, his overall wear rates became much higher when employing high speed cutting, thus leading to accelerated wear. Pieces of less expensive tools capable of softer metals will exhibit an unflattened wear of speed by a staggering 40% while cutting through aluminum instead of steel.

- Surface Finish: Attaining a smooth surface finish is essential for functional and esthetic reasons. Aluminum’s softness, however, increases the risk of burr formation during cutting. Some sources indicate that the height of the burrs is highly variable between 0.2 mm and 1 mm with consideration of cutting speed and tool sharpness, adding further finishing requirements.

- Material Thickness Variability: Performance of the various operations may be impacted by the thickness of the aluminum sheet. For example, cutting thick sheets tends to elevate the required tool forces, thereby decreasing the precision of the cut. It has been noted that sheets over 6 mm in thickness often require specialized topcutter equipment to achieve the specified tolerances.

- Machine Compatibility: Not all machines Drawing operations are maximally suitable for processing aluminum. Even machines built for steel cutting may lack the required dimensional accuracy parts and cooling features needed to work on aluminum, rendering them useless or damaging the machine.

These challenges can be properly and efficiently solved if there is sufficient care in the method of planning, tool selection, and following provided cutting guidelines suitable for Aluminum’s properties.

How Do You Start Your First Sendcutsend Project Today?

The Information and Specifications for Laser Cutting Aluminum

The efficiency of any project utilizing aluminum for laser cutting will depend largely on how well one understands material specification and performance data.Below are critical parameters and data to note.

Thickness of the Material: The thickness of aluminum sheets used for laser cutting falls within 0.02 inches (0.5 mm) to 0.5 inches (12.7 mm). Laser cutting of thicker materials may require special settings or equipment.

Speed of Cutting: The cutting speed is affected by aluminum’s reflectance. Typically, CNC laser systems work anywhere between 20 to 80 IPM (Inches Per Minute).

Power of the Laser: For thinner aluminum sheets, a minimum of 300-500 watts laser power is required while stronger systems of over 2000 watts are advisable for thicker materials.

Width of Kerf: The kerf or cut width averages between 0.004 inches and 0.015 inches, depending on the laser type and focus which ensures precise cuts for detailed parts.

Heat Affected Zone (HAZ): Cuts and proper cooling systems help control heat distortion. Proper HAZ control ensures smooth edges without softening the material.

All these specifications help improve project efficiency and quality in aluminum laser cutting. Always check the manufacturer’s guidelines to best set the machine parameters according to the project’s precise needs.

Understanding Pricing and Instant Pricing with Fabrication Options

In setting strategies for a particular project during an evaluation of instant pricing and fabrication services, a number of key issues and options need careful assessment. A stand-alone list of very important items is provided hereinafter.

Available Materials: Types of metals: aluminum, stainless steel, carbon steel, brass, copper and titanium. Plastics.

Thickness Range: Varies from 0.5mm to 25mm depending on the type of material.

Cost factors: Market price of material grade/ thickness/ price per sheet of material/ current market rate if applicable.

Preferred Methods of Cutting

Advantages: Highest possible precision and cleanness of edges with respect to post-processing operations (if any) .

Disadvantages: Effectiveness on reflective materials is minimal.

Advantages: No HAZ means that it is appropriate for thermal sensitive parts.

Disadvantages: Operationally much slower, more expensive.

Advantages: Medium precision, low price for thick sheets.

Disadvantages: Larger HAZ than with laser cutting.

Edge Quality: Set finer or coarser limits.adjust fine cutting to edge tolerances.

Part Marking: Etching, engraving mark texts, select marking methods by specification and label marking.

Hole Patterns: Arrangement of standard shapes or complex ones set in intricate arrays.

Material Used: Value of work is determined by mass or on area worked on.

Creation of holes in workpieces is done under controlled parameters for specific parts that lead to pre-determined patterns instead of random shapes.

Total process time for the work is proportional to complexity of work on a controls the work and speed of the machine. Work on detailed components take more time but in a considerable rate compared to bulk jobs.

Smaller batches will pay higher prices per unit due to increased cost applied compared to larger orders due to economies of scale.

Usually projects achieved in 2 to 7 business days.

Gap fee structure applies for urgent design and expedite workflow options.

This complete evaluation assists in analyzing the specific The Optimizing Service Parameters, Project Budgets, and Timelines. Always check platform or provider-specific services to ensure accuracy relavant to platform requirements.

Custom Sheet Metal Projects Tips

The materials that are most often utilized in sheet metal fabrication are aluminum, stainless steel, and carbon steel. The lightweight and corrosion-resistant aluminum is flexible, durable, and can be used in many applications. Stainless steel has great strength and corrosion resistance so it is best used in moist areas or places where chemicals are used. Carbon steel is tough and affordable, making it a good choice for structural and industrial projects. The materials are selected based on the rigorous environmental conditions and the Project specifications regarding weight and strength.

How to Ensure Quality in Laser Cut Parts?

The Need for Deburring and Burr Removal

In laser cutting, quality assurance hinges on the effectiveness of the deburring and burr removal process. Working against quality is the presence of burrs—small or raised rough edges on the surface of a part which can affect its utility and beauty. Quantitative research shows that parts which are not properly deburred are likely to have higher failure rates in more product assembly, and it has been estimated that there could be as much as a 20% increase in defect rate caused by burrs.

Different methods can accomplish deburring, such as mechanical grinding, vibratory finishing, and chemical deburring. Mechanical grinding is good for thicker materials; however, it can produce very rough cuts if not executed properly. Smaller parts, including those with complex geometries are best handled using vibratory finishing as all burrs will be removed without roughing the part up. Studies of manufacturing workflows indicate that companies employing automated deburring systems complete more work in a given time, reporting between 30-50% greater production efficiency than manual systems.

Evaluation and monitoring are important for achieving and maintaining quality and must be done regularly. Visual inspection and gauging like surface roughness measurement, alongside automated scanning, can detect even the smallest burrs. With these measures, manufacturers are able to improve and take advantage of their processes while avoiding losses. Additionally, these manufacturers enjoy meeting stringent regulatory requirements, like ISO 9001.

Methods in Fabrication of Sheet Metal

The procedures associated with sheet metal fabrication move through a number of clearly defined steps which are further divided into sub-procedures-below describes some common methods:

Description: A machine or person cuts straight lines in a sheet of metal using a straight blade cutting tool.

Advantages: Produces clean edges at a very fast rate.

Applications: Serves as a first step in processing raw metal work pieces.

Description: Metal is cut or engraved using a laser, which is housed in a laser cutter that has been placed at another workstation.

Advantages: Very precise while also conserving material, as it can perform intricate designs.

Applications: Auto parts, decorative panels, and parts for aircraft.

Description: Using a punch and die, material is removed from the surface of a sheet through pressing the punch using a die onto the surface.

Advantages: This is a good method for mass production.

Applications: Used to put holes for screws, ventilation, or some design components on a panel.

Description: Angles or other shapes are given to a piece of metal using bending machines or brakes presses.

Advantages: Accurately and consistently delivers bends of exceptional quality.

Applications: Ducts for HVAC systems, brackets, and enclosures.

Description: Raises or indents designs into the sheet with a die.

Advantages: Useful for mass production.

Applications: Logos, serial numbers, and other trims.

Description: Bonds metal parts by burning them with great heat.

Advantages: Assembly is strong and durable.

Applications: Frames, supports, and other structural items.

Description: Includes polishing, coating, or painting to alter the appearance and reduce corrosion.

Advantages: Increases the lifespan of products and their attractiveness.

Applications: Consumer goods, exterior fittings, and machinery.

All of these combined techniques help in creating metal sheet products that conform to exact requirements in functionality, strength, durability, and good looks. Most modern machinery is designed to improve precision and optimize time during production processes.

Ensuring Precision with CAD and CNC Technologies

The adoption of Computer-Aided Design (CAD) and Computer Numerical Control (CNC) have transformed all industries. Through CAD applications, users can create exact designs and models of components to be fabricated and make sure all details are right before any production steps are undertaken. These designs are then brought to life by CNC machines that cut, shape, or mill components according to provided digital drawings, with hand tools and machines. Verification is done electronically, and production processes are fully automated. CAD and CNC working in conjunction increases output, minimizes mistakes, and provides uniformity in mass production.

Reference Sources

- Title: Experimental Investigation of Kerf Width and Kerf Taper in Fiber Laser Cutting of Aluminium Alloy

- Authors: P. Kharche, D. V. Patil

- Publication Date: April 20, 2023

- Summary: This study investigates the kerf width and kerf taper during the fiber laser cutting of aluminum alloy. The authors conducted experiments to analyze the effects of various cutting parameters on the quality of the cut. The results indicated that the cutting speed and laser power significantly influenced the kerf width and taper.

- Methodology: The research involved experimental setups where different parameters such as laser power, cutting speed, and assist gas pressure were varied. The kerf quality was assessed using optical and scanning electron microscopy(Kharche & Patil, 2023).

- Title: Analisa Cacat Timbul pada Material Aluminium Akibat Pemotongan Menggunakan Laser Cutting

- Authors: Karyadi Karyadi, Rizki Aulia Nanda, Ade Suhara

- Publication Date: October 3, 2023

- Summary: This study focuses on the defects arising from laser cutting of aluminum alloy type 1050A with a thickness of 0.8 mm. The research aimed to determine the optimal cutting speed to minimize defects. The findings showed that the lowest defects occurred at a speed of 33 mm/s, with minimal defects ranging from 0.004 mm to 0.008 mm.

- Methodology: An experimental method was used with variable speeds of 33 mm/s, 55 mm/s, and 88 mm/s. The defects were measured using a digital dial indicator(Karyadi et al., 2023).

- Title: Thermal and Morphological Analysis of the Interaction Effect of Different Assist Gases with Gas-Filled Closed-Cell Aluminium Foam During Laser Cutting Process

- Authors: M. Raza, Susmita Datta, P. Saha

- Publication Date: May 30, 2020

- Summary: This paper examines the effects of different assist gases on the laser cutting of closed-cell aluminum foam. The study found that the type of assist gas significantly influenced kerf quality, with argon providing the minimum kerf width and nitrogen producing the least dross.

- Methodology: The authors used a 2-kW fiber laser system and varied process parameters, analyzing kerf quality through optical and metallurgical analysis(Raza et al., 2020, pp. 1958–1969).

Frequently Asked Questions (FAQs)

Q: What should I know regarding the laser cutting services of aluminum and sheet metal?

A: The services include precise cutting into custom shapes using laser technology which is suitable for both industrial and hobbyist use because of its high skill, precision, and efficiency.

Q: What is the process of laser cutting a sheet of aluminum metal?

A: Laser cutting consists of melting, burning, or vaporizing sheet metals with pinpoint light cuts controlled by CAD designs which helps create very intricate and precise designs.

Q: Is there any viability of using 5052 aluminum in laser cutting?

A: 5052 aluminum is very much prone to being used in laser cutting as it has amazing anti-corrosion properties and ease of formability, making it custom for custom sheet metal parts.

Q: What is the maximum thickness of aluminum that can be cut using laser technology?

A: Commonly, laser technology can effectively cut aluminum to sizes of 1 inch in thickness with variances on the power of the laser as well as the material’s reflectivity.

Q: Can powder coating be applied to aluminum parts that have been laser cut?

A: Indeed, a laser-cut aluminum part can have powder coating applied to it. Its practical value as a finishing process for aluminum parts is unique because of its durability, aesthetic appeal, protection against corrosion, and because it comes in multiple colors and textures.

Q: What are the advantages of custom laser cut parts?

A: Reduced operational costs such as reduced time required, reduced material waste, ability to operate at higher volumes, and ease of replicating designs are just some of the many advantages custom laser cut parts offer.

Q: In what ways is tube laser cutting different from ordinary sheet metal cutting?

A: In comparison to ordinary flat sheet cutting, tube laser cutting allows for more detail and customization when cutting tubular or cylindrical materials such as pipes.

Q: How can I obtain custom parts from an online laser cutting service?

A: You can obtain custom parts from an online laser cutting service by placing an order and providing the service with your desired CAD specifications, like STEP or DXF files. After that, the service provider will use advanced cutting lasers to cut the designs shared so they can be sent to the orderer.

Q: What important aspects need to be addressed when picking a company to perform the custom parts metal cutting service?

A: The reputation of the metal cutting service provider, the materials available, level of customer support, service pricing, and if modern technology such as laser cutters are available should all be factored in considering who to work with.

Q: Can reflectivity of aluminum damage the laser during cutting?

A: When most people think reflectivity, they only consider it in terms of messing; we place caution on cutting head, but we can’t put caution on the rest of our laser equipment, especially the laser itself. But we still need to use the most modern laser mirror cutting aluminum with a laser mirror cutting machine that reflects all rays safely.