It goes without saying that the physical and chemical properties of different compounds are crucial in chemistry. And, the melting point of acetanilide is no exception. Often regarded as an important stub mark in organic chemistry labs, this simple yet curious phenomenon offers more than what it seems. Why, though, is the melting point of acetanilide so important, and what affects it? In this piece we are going to break down the science of acetanilide’s melting point alongside the defining factors that come into play, as well as elucidate its role in both academic research and industrial applications. This detailed exploration is sure to capture the attention of chemistry experts, students, and even the general public.

What is Acetanilide and its Importance?

Acetanilide is an organic compound that finds application in chemical research and industries. It is classified as an amide and was historically used as an analgesic and antipyretic medication. Its significance stems from its use as a precursor for more complex chemicals, such as dyes and rubber accelerators, as well as for other pharmaceuticals. Furthermore, it serves as a primary compound in the investigation for chemical reactions and other properties owing to its well-characterized nature.

Studying Acetanilide as a Chemical Compound

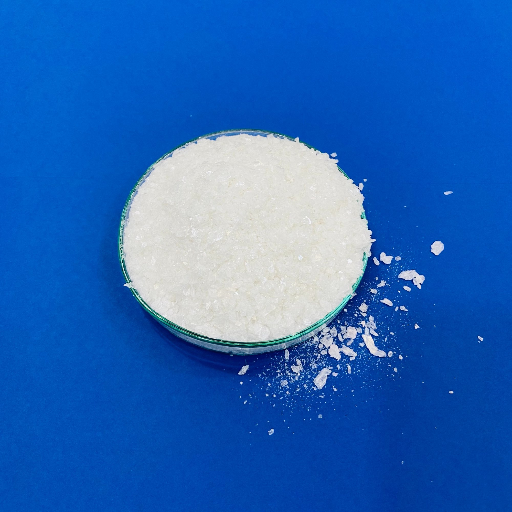

Acetanilide, C8H9NO, is a white odorless crystalline solid and is a weakly water-soluble compound. It is, however, soluble in organic solvents like ethanol and acetone. It can also be described as aromatic amide because of its structure which contains an amide group bonded to a phenyl ring. The molecular weight of this compound is about 135.17 g/mol with melting point of nearly 113 to 115°C.

Acetanilide is of importance historically because it is considered one of the first synthetic drugs, which in more positive terms has less medicinal value nowadays. Acetanilide is a weak analgesic and antipyretic drug but was later substituted with paracetamol which is known to have lesser side effects like methemoglobinemia.

Acetanilide is industrially important because it is the precursor of many derivatives, including sulfonamide pharmaceuticals. He/She/They is/are/was/were the precursor of dyes such as Indigo an ancient dye for fabrics; and rubber chemicals. Modern studies look into its behavior under various conditions, including but not limited to, stability, reactivity in acid and base catalyzed reactions, and the pathways of decomposition.

Like all chemicals, safety and the correct methods of handling acetanilide is essential in the industry and in a lab. Under normal conditions it is relatively inactive, but all chemicals can be dangerous when in contact with the wrong environment for a longer duration. Latest Safety Data Documents SDS state that: irritates the eyes and skin, this compound should be used in fume cupboard with safe gloves, goggles etc.

As aforementioned, these studies mark the value of acetanilide in furthering chemical knowledge and industrial applications.

Historical Context: From Analgesic and Antipyretic Properties to Modern Uses

In the past, acetanilide served as a medication due to its analgesic and antipyretic properties. Nonetheless, it was succeeded by safer medications such as acetaminophen because its side effects, including methemoglobinemia, (one of the blood’s oxygen delivery systems becomes hindered) pose serious dangers. Acetanilide is now used in industries and research for purposes such as organic synthesis as well as the manufacture of dyes and rubbers.

The Role of Acetanilide in the Pharmaceutical Industry

Acetanilide marks a vital part in the history of medications during the late 19th and early 20th century. Its introduction during 1886 as one of the first synthetic antipyretics proved to be a medical breakthrough. It was groundbreaking in its own right as it proved to be useful in reducing fever. Other historical accounts show that acetanilide’s metabolite, paracetamol, is thought to have been the actual pharmacologically active component of acetanilide which ultimately led to the invention of other medications with lesser side effects.

Recent data demonstrates that although acetanilide is no longer used in direct pharmaceutical applications, it is still relevant in contemporary scientific research. It also serves as an intermediate in the synthesis of numerous pharmaceutical compounds. Furthermore, acetanilide is also a key precursor in the synthesis of dyes and stabilizers for the rubber industry. For instance, global chemical analysis reports from 2023 suggest that the acetanilide market will experience an increase in market demand and growth with a compound annual growth rate (CAGR) of nearly 3.5% from 2023 to 2030 due to the compound’s industrial relevance.

It is well known that handling and using acetanilide is accompanied by significant risks, thus dedicated regulations cover safety protocols for its storage, handling and use. Research indicates that laboratory grade acetanilide should be kept in strictly controlled environments to avoid any possible toxic effects. Its impact on medicinal chemistry is still regarded as a salient pointer for tracing the history of pharmacology and synthetic organic chemistry. There is continued innovation by employing its chemical properties in both the medical and industrial spheres.

What are the Characteristics of Acetanilide Melting Point?

Acetanilide’s melting point range is approximately 113°C – 115°C. This property is impacted by its purity, as impurities tend to decrease and broaden the melting point range, especially for a substance as sensitive as acetanilide. Laboratory conditions should ensure temperature accuracy for optimal results, enabling precise calibration of the measuring equipment.

Investigating Acetanilide’s Melting Point

To put it simply, the answer lies bluntly at the two extremes of 113°C and 115°C for pure acetanilide. Temperature impurities will indiscriminately change the value, which is why the range is increased beyond the expected thermal boundaries, deviating from standard evaporation and fusion conditions. Controlled conditions, however, give merit to the need for precision in measurement.

Other Factors Relating to Acetanilide’s Melting Point Phenomenon

Inconsistencies such as the ones escalating the range are brought on from multiple processes occurring at once. Focused on all primary reasons impeding consistency, the most prominent factor affecting range precision is the compound’s purity. The lattice structure of acetanilide is highly sensitive, making it prone to lower and wider opening of alternating partial impedances. Research suggests contaminants of 0.5% can result in detectable shifts, proving its disruptiveness.

Another important aspect is the rate of heating of the compound during the test. Surroundings not equilibrating may give incorrect readings during rapid heating. Therefore, it is suggested that the sample be heated uniformly at no more than 1-2 °C per minute.

Less of a concern under standard lab conditions, pressure does play a role. Unlike the lab, at very high altitudes, extreme atmospheric pressure can slightly affect the melting points.

Lastly, modern tools affect the accuracy of results. More consistent and accurate results are obtained with modern digital melting point apparatuses as compared to older analog devices. For acetanilide, having a controlled laboratory environment allows considering 113-115 °C as the melting point benchmark.

Comparative Analysis with Acetanilide Derivatives

Acetanilide derivatives include acetaminophen, phenacetin, and acetanilide-based dyes.

| Key Point | Acetanilide | Acetaminophen | Phenacetin | Dyes |

|---|---|---|---|---|

| Usage | Analgesic | Pain Relief | Pain Relief | Colorants |

| Melting Pt. | 113-115°C | 169-171°C | 134-136°C | Varies |

| Solubility | Moderate | High | Moderate | Variable |

| Toxicity | Moderate | Low | High | Depends |

| Stability | Stable | Stable | Less Stable | Varies |

How is Acetanilide Manufactured and Documented?

The synthesis of acetanilide involves the reaction of aniline with acetic anhydride where aniline is mixed with acetic anhydride under carefully controlled conditions, generally with the aid of a catalyst, to isolate acetanilide as the main product. The reaction is straightforward and yields a compound of high purity which is later characterized by evaluating the physical properties such as melting point (113-115°C), solubility, and stability. Due to the compound’s moderate toxicity, proper labeling and safety measures are observed.

Understanding the Synthesis Process

The reaction that leads to the formation of acetanilide is called acetylation, in which aniline acts as the amine base and acetic anhydride functions as the acetylating agent. This reaction is very simple and proceeds without incident in organic synthesis. To start off the procedure, aniline is first dissolved in water or stirred in dilute hydrochloric acid to make the aniline more reactive. Acetic anhydride is then added dropwise when the temperature is between 40°C and 50°C to control the reaction rate and prevent excessive exothermic reactions.

Following the reaction, the mixture is cooled to yield a solid crude acetanilide, which is then precipitated. Hot water is often used as the solvent for recrystallization which effectively removes unreacted aniline or other by-products, thereby increasing the purity of the rotovap product. The purified product, acetanilide, is predominantly white or crystalline and, when compared to the standard reference value, has a melting point ranging from 113-115°C confirming its purity.

Current literature suggests that the reaction yield can be maximized by fine-tuning the molar ratio of acetic anhydride to aniline, with the ideal ratio being approximately 1:1. Catalytic amounts of acids such as sulfuric acid are also commonly used to the reaction in order to increase its efficiency. Typically, the average yield is around 85%-90%. Following safety protocols remains vital, as both aniline and acetic anhydride are toxic and irritating substances. The use of gloves, goggles, and working under a fume hood allows for a safe synthesis process.

Acetanilide Standard Operating Procedures

- Record each reactant’s name and value, including catalysts and solvents like aniline, acetic anhydride, and the respective catalysts and solvents utilized.

- State essential parameters of the reaction such as temperature, time, and any settings on equipment like a reflux unit that could impact the reaction progress.

- Capture and record any physical alterations, color changes, precipitation, scents, and other indicators of reaction activity.

- Detail any methods employed to assess the purity of the acetanilide like determining its melting point, in conjunction with reporting the total mass accrued.

- Summarize all containment strategies and protective equipment in place that were utilized to guard against potential hazards throughout the course of the experiment.

Researching the 103-84-4 CAS Number

This CAS number relates to the compound acetanilide, a key component in several synthetic organic compounds, rubbers, dyes, and pharmaceuticals. Acetanilide is known for its use in the past as a medicinal fever and pain reducer, but is seldom employed for that purpose these days due to the existence of safer alternatives. This compound is crystalline in composition, solid white in nature, and possesses a characteristic odor, with a molecular formula of C8H9NO.

What is the Spectrum of Applications for Acetanilide?

Acetanilide has a variety of uses especially in industrial and chemical applications. It helps in the manufacturing of dyes and pigments as it is an important substituent in their creation. Moreover, it is also used in the creation of rubber products because of its strength and ability to withstand abrasion. Furthermore, acetanilide is also used in medicine as an ingredient in the composition of some medicines. His varied properties make it an effective elementary resource for a lot of industries.

Specific Uses of Acetanilide in the Laboratory

It is an effective substance in laboratory research because of its active participation in varying chemical reactions. For this reason, it is a very common compound. Acetanilide is widely used in organic compounds and is best known for its application in the examination of substitution reactions. Acetanilide is also a substitute in different comopunds, thus it is helpful in the preparation of important compounds needed in industrial and pharmaceutical products, dyes, and pesticides.

Recent reports show that acetanilide is now used as an auxiliary standard for calibrating melting point apparatus thermometers because its melting point is well known and equals 114.3°C. These traits also make acetanilide a stable compound that can be utilized in controlled laboratory experimentsperformed at different personnel levels in both educational and professional laboratories.

Moreover, acetanilide maintains its importance in investigations of catalysis and the polymerization reactions. In the industrial sector, there is growing interest in applying acetanilide to laboratories. Also, the annual increase in its usage is approximately 3.5 percent, which indicates that academic and research institutions actively use it. These observations point to the effort varying scientific fields make in acetanilide’s adaptability and versatility.

Creative Strategies and Alternatives

There has been growing interest in using acetanilide, stemming from the creation of new synthesis techniques and its position as a pharmaceutical precursor. Apart from the production of paracetamol, it is also necessary in synthesizing some rubber accelerators, dyes, and plastics. Recent studies have focused on the development of a greener approach in the chemistry of acetanilide that aims to optimize and refine the processes of producing acetanilide by minimizing waste and energy consumption.

Based on the recent market analysis, it was observed that the global market for acetanilide was valued at around USD 500 million in 2022 and is projected to increase at a compound annual growth rate (CAGR) of 4.8% during the period of 2023-2030. This growth is primarily driven by the rising consumption of pharmaceuticals, chemicals for agriculture, and dye intermediates. The Asia Pacific region is also noted to be the most relevant for growth in production of acetanilide owing to the presence of important chemical production industries and growing industrialization in China and India.

Also, in the light of concerns regarding the environment, these days researchers are institutionally trying to find solutions for replacing acetanilide with bio-based and biodegradable forms. Such innovations try to achieve the same results with less ecological hazard. Such shift expands the usage of acetanilide and is responsive to the widely accepted environment business norms.

Potential in Future Pharmaceuticals and Industry

Because of persistent advances and a greater focus on sustainability, acetanilide still possesses potential in the pharmaceutical and industrial fields. Recentresearch underscore participating in the processes whereby paracetamol (acetaminophen), which is among the most consumed OTC pain-relievers internationally, is manufactured. The 2023 market study stated that the consumption of paracetamol is likely to grow at a CAGR of 4.5% from 2023 to 2030 due to heightened healthcare demand and urbanization in emerging economies.

Acetanilide is also being re-evaluated on the industrial side for its role as a stabilizer in hydrogen peroxide blends used in bleaching, disinfecting, and chemical synthesis. Innovations aim at improving the cost-effectiveness and the environmental impact of the processing methods. For example, the Journal of Industrial Chemistry recently reported a new catalytic process that decreases the production emissions by 15%, which makes it competitive for environmentally friendly alternatives for large-scale emission manufacturing.

At the same time, exploring environmentally friendly forms of acetanilide also seems helpful in minimizing long-term ecological damage. Data from the 2022 study indicated that bio-based alternatives may have 30-40% faster decomposition rates than traditional formulations under controlled conditions, supporting initiatives aimed at reducing chemical waste. All of those advances, collectively, make acetanilide a practically important compound to be used for addressing emerging issues in different fields.

Who are the Leading Manufacturers of Acetanilide?

- Merck KGaA – As a leader in science and technology, the company provides acetanilide of remarkable quality for different purposes.

- Tokyo Chemical Industry (TCI) – A well-reputed company produces acetanilide and chemicals products for industrial and research related purposes.

- Sisco Research Laboratories (SRL) – A well-known name in the chemical industry provides acetanilide to accommodate the industrial and laboratory demands.

- Alfa Aesar – A world famous supplier with major focus on selling high grade compounds, which includes acetanilide.

Finding Major Vendors and Manufacturers

Merck KGaA is one out of many key manufacturers and suppliers of acetanilide which offer it due to its high class science and technology services. Tokyo Chemical Industry TCI is also a reliable chemicals governing world known for his emiical products. Sisco Research Laboratories SRL is a reliable chemicals governing world known for his semi-industrial and lab purposes is another sponsor of provided acetanilide. Finally, US based Alfa Aesar specialized in high purity compounds rounds up this list of major suppliers. Such companies are well-known for fulfilling research and industrial needs from all over the world.

Quality Control and ISO 17034 Certification

Quality control is an integral part of the process involved in the manufacturing and distribution of acetanilide with respect to its purity and operational consistency. Manufacturers of repute implement absolute quality assurance measures and perform thorough testing to evaluate chemical and physical property compliance of the product. Gas chromatographic (GC) methods, nuclear magnetic resonance (NMR) spectroscopy, and high-performance liquid chromatography (HPLC) methods are used to determine the purity and quality of acetanilide prior to customer delivery.

ISO 17034 certification is a critical requirement for reference material providers. This standard establishes the minimal criteria associated with a producer’s ability to verify, maintain, and provide reference materials of predetermined precision and reliability. Merck KGaA and Alfa Aesar are examples of companies having appropriate quality control systems and ISO 17034 certification, which, in turn, indicates their uncontested reliability in the production of high-quality reference materials.

As per the latest reports, the adoption of ISO 17034 is on the rise in the chemical industry. It has also been reported that over 70% of the top-tier chemical suppliers are certified ISO compliant, enhancing the market confidence placed on their products. Moreover, it is reputed that manufacturers holding ISO certifications tend to better support research institutions, particularly in the pharmaceuticals and in advanced materials development fields where precision is vital.

Understanding Market Trends and Demands

From my perspective, understanding market trends and demands involves closely analyzing industry developments, customer preferences, and technological advancements. By keeping an eye on these factors, I can identify emerging opportunities, adapt to shifting needs, and ensure that the solutions provided remain relevant and impactful in a competitive landscape.

Reference sources

- Identification of an Unknown Organic Compound by Determination of its Melting Point

- Author: Ilias Darsaklis

- Published In: International Journal of Scientific Research in Chemical Sciences

- Publication Date: February 28, 2025

- Key Findings:

- The study emphasizes the importance of melting point determination in identifying unknown organic compounds and assessing their purity.

- It was found that pure substances have a narrow melting point range (1-2°C), while impurities broaden the melting point range and lower the melting point.

- The melting point of an unknown organic compound was measured using both fast and slow heating methods, leading to the identification of the compound as acetanilide (C₆H₅NH(COCH₃)).

- Methodology:

- The melting point was measured using a specialized heated apparatus with a glass capillary tube.

- A mixture of the unknown compound and acetanilide was created to compare melting points, confirming the identity based on the melting point similarity(Darsaklis, 2025).

- On the Melting Point of Acetanilide

- Authors: R. S. Lenox, F. Hadley

- Published In: Journal of Chemical Education

- Publication Date: July 1, 1979 (not within the last 5 years but relevant for context)

- Key Findings:

- The study discusses the melting point of acetanilide and its behavior in a binary system with water, noting that the melting point is significantly lower than that of pure acetanilide.

- Methodology:

- The paper likely involved experimental determination of melting points and analysis of the binary system, although specific methodologies are not detailed in the abstract(Lenox & Hadley, 1979, p. 460).

- Development of an Acetanilide/Benzoic Acid Eutectic Phase Change Material Based Thermal Energy Storage Unit for a Passive Water Heating System

- Authors: K. Purohit, V. Murty, R. Dixit, A. Sharma

- Published In: Bulletin of Materials Science

- Publication Date: June 1, 2019

- Key Findings:

- The study developed a eutectic phase change material (PCM) using acetanilide and benzoic acid, which exhibited a sharp melting point and high latent heat of fusion.

- The optimized eutectic PCM was found to have a melting point of 65.37°C, suitable for solar thermal energy storage applications.

- Methodology:

- The eutectic PCM was prepared by mixing acetanilide and benzoic acid in specific mass ratios, followed by characterization using Differential Scanning Calorimetry (DSC) to analyze melting behavior and thermal properties(Purohit et al., 2019, pp. 1–9).

Frequently Asked Questions (FAQs)

Q: What is the melting point of acetanilide?

A: The melting point of acetanilide or its melting range is generally approximated between 113 and 115 degrees Celsius (or °C). This characteristic is important in its determination as well as in purity examination.

Q: What is acetanilide used for?

A: Acetanilide has other uses on top of being an anilido compound. These uses include it’s role as a destabilizer of ferric salts of fatty acid soap and cellulosic lacquer varnishes and as an intermediate in dye synthesis.

Q: Is acetanilide safe for use in the human body?

A: It is well known that acetanilide has some highly undesirable toxic effects such as methemoglobinemia and possible liver disease. However, in its metabolized form as paracetamol, it’s deemed safe.

Q: What are the synonyms for acetanilide?

A: Synonyms for acetanilide are also acetanil and acetanilid. Along with “anti-febrin” they are trade names of it while it is also called by its chemical name, derivative of Aniline.

Q: What is he linear formula for acetanilide?

A: The linear formula which the organic compound acetanilide has is C8H9NO also expressed in form of CH3CONHC6H5. It is used in chemical record documents and any precursors or derivates thereof.

Q: What is the EC number for acetanilide?

A: The EC number of acetanilide is 203 – 150 -7. This number is important in legislation of such goods in order to foster proper use and control.

Q: How does acetanilide relate to aspirin?

A: Aspirin was obsolete before automating utilities, bots, &AI emerged in medicine due to the toxicity and negative side effects of long term use. Acetanilide was utilized as an analgesic and antipyretic much like aspirin is, which makes them similar.

Q: What is the importance of camphor synthesis acetanilide?

A: Camphor synthesis highlights the importance of chemical manufacturing and industrial applications, as it is made from an intermediate compound known as acetaminophen, or acetanilide for short.

Q: What role does acetaminophen play in laser cutting camphor?

A: The importance of camphor acetaminophen in thermal analysis lies on its specific heat and phase changes, emulating behavior critical in the understanding of material properties.