From engraving serial numbers on medical devices to etching logos onto goods, laser marking technologies have found application everywhere. Efficient, permanent engraving becomes indispensable in businesses requiring marking of numerous materials. However, as in every other field, different laser marking methods exist, each optimized for different applications and varying in terms of cost-effectiveness, quality, and durability.

Everything you need to know about the most common types of laser marking technologies, such as fiber and CO2 lasers, their most effective applications, and the latest developments in the field is provided in this guide. Newcomers and the more experienced will find the comprehensive information useful. Keep exploring to find the best method fulfilling your requirements.

What Are the Different Types of Laser Marking?

- Engraving: Uses the laser to cut or remove surfaces deep on objects and leaves a lasting mark permanent mark. Mostly used on metals and tough plasters.

- Etching: Also a similar process as engraving but shallower marks in comparison. Usually used on bar codes and identification numbers.

- Annealing: Marks are created through heating a material’s surface without actually removing anything, this mostly affects metals like stainless steel.

- Color Marking: Is used for branding or even for decorative purposes and different effects are achieved on marking materials.

- Foaming: Marks are raised by heating certain plastics and a lighter or darker contrasting area is created.

Factors Affecting Fiber Laser Marking Performance

As with any other technology, fiber laser marking performance is dictated by a number of critical factors, including marking speed, laser frequency, focus setting, and type of material. The best results are achieved when all parameters are set to the appropriate levels.

- Marking Speed: In high production environments, increasing the marking speed is important in reducing the processing time. However, swift motions may adversely affect clarity and depth of markings on tougher materials. For example, some studies show poor engraving quality on dense metals like titanium or stainless steel at higher speeds.

- Laser Frequency: The overall texture and also the contrast of markings are affected by laser pulse frequency. Frequencies produce the best results on smooth and detailed designs on anodized aluminum surfaces, while deeper engravings with lower frequencies suit softer plastics or metals.

- Focus Adjustment: Sharper focusing of the beam results in high energy density and precision accuracy in the marking of parts. Horizontal pull, vertical push, and other advance auto-focus schemes are widely adopted because they maintain quality in high volume industries like medical device assembly or aerospace component manufacturing.

- Material Type: The specific marking strategy to be used will depend greatly on the type of material. Metals typically need more energy demanding parameters than plastics or ceramics. For instance, some newer fiber laser systems can now mark gold and copper, along with other materials that were previously deemed too reflective, with great detail.

Industry studies show that fiber laser systems are incredibly flexible; marking simple geometric shapes at a staggering 7,000 mm/s and sustaining well under a micron of spatial accuracy. Such changes not only improve productivity, but they also expand more complicated micro-marking tasks on circuit boards to logos on consumer items. Each case is optimized individually to ensure the best outcome based on the set parameter conditions.

The Role of CO2 Laser in Marking

CO2 lasers actively mark a wide variety of substrates and organic materials, including plastics and some metals with special coatings, forming graphics and letters on the surface. CO2 laser systems are efficient for marking and engraving non-metals; organic and polymer-based materials have a strong absorption at the wavelength of 10.6 µm. Hence, they are well suited for marking applications like date coding on food packages, engraving on wood and glass, as well as enduring marks on rubber or leather products.

The capabilities of CO2 lasers in marking processes can be defined by the specific marking speeds of up to 12,000 mm/s for certain materials with basic marking features. In addition, modern CO2 laser systems have advanced galvanometer scanning and other more sophisticated optical systems, enhancing quality, consistency, and repeatability even in low unit cost mass production. For example, these systems are widely used for marking in the packaging and automotive industries, which require high accuracy and speed due to the need for fast and accurate marking as well as regulatory constraints. Flexibility in machine settings such as pulse frequency and power levels enable marked customization from surface etching to more pronounced engravings while still preserving the material.

The Benefits of UV Laser Marking in Precision Applications

UV laser marking systems are well known and regarded in the industry for creating exceptionally detailed and intricate marks, achieving exacting standards across diverse materials and therefore being useful in cross sectors. This is due to the cold marking process made possible by pulses at 355 nm which have narrow ranges of heat-affected material zones, thereby protecting the integrity of the material. This makes them most useful for delicate materials such as plastics, glass, and ceramics.

New developments in UV laser technology have improved their functionality. For example, it is reported that high frequency pulsed lasers have micro-marking resolution capabilities of up to 20 microns. Such precision is paramount in electronics or medical devices industries which require compact marks such as QR codes or serial numbers for traceability — compliance needs— and for the devices themselves.

Moreover, the operational UV laser systems require lower amounts of energy, and their lifespan is longer. These systems have lifetimes over twenty thousand hours, which makes marking documents more affordable with extended use. Other studies have documented less operational downtime successfully, due to modern designs with automated calibration features and reliable beam stability.

The combination of such factors makes UV laser marking precision tools for advanced manufacturing processes.

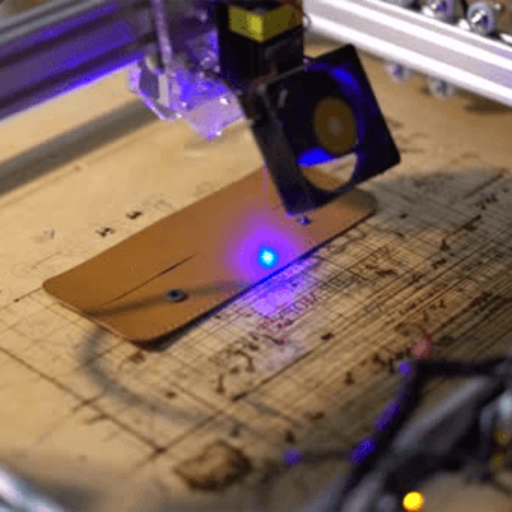

How Do Laser Engraving Machines Work?

Factors That Influence Laser Marking Efficiency

The efficiency of the laser marking process is based on several important parameters such as the marking speed, wavelength, pulse frequency, and material absorbance. It has been researched that certain materials such as glass and polymers high effective at absorbing energy and work best with shorter wavelengths like ultraviolet (UV) lasers at 355 nm. These materials undergo a precise blation when exposed to a laser of the right wavelength and there is very minimal thermal damage which reduces the risk of destroying sensitive materials.

Pulse frequency is vital when it comes to determining the achieving the desired quality and speed of marking. Marking is done at higher rates of pulse frequency which yield smoother engravings and shallower depth which works fine for surface engravings. At lower rates of engravings, deeper impression more intricately but may affect the sharpness of the design.

Also important is the absorptivity of the material used. Reflective metals like stainless steel and aluminum would require treatment with infrared or fiber lasers while plastics will use UV or green lasers which are shorter. Marking the right conditions, tailoring them to the material’s properties might raise the efficiency of manufacturing lines by 30%according to performance preliminary tests.

Precision and speed need to be in balance at all times. The quality of marking done by automated systems using modern motion control systems can exceed the speed of 7,000 mm/s. This particular advancement is beneficial in high-volume production environments such as the electronics and automotive industries.

Modern innovations, along with specific parameter adjustments, have made it possible for laser marking machines to sustain high productivity with remarkable accuracy across a wide variety of materials.

Components of a Laser Engraver

- Laser Source:

Any laser engraver must have a laser source. It defines the productivity of the machine as well as the various applications it can cover. For instance, Fiber lasers are popular for engraving on metals because of their accuracy, durability, and high marking speed. Research shows that fiber lasers can have lifespans exceeding one hundred thousand hours, which is beneficial for industrial purposes. They can be quite affordable. On the other hand CO₂ lasers works perfectly for non-metal materials like wood, glass, and plastics.

- Galvanometer (Galvo) Scanner:

The laser galvanometer scanner is made up of high speed mirrors that are energized to rotate the laser beam. Modern galvo systems can achieve scanning speeds of more than 15,000 mm/s as per the requirements. This unit makes sure that the laser beam pointer moves with the required accuracy and provides complex engravings on wide range of materials.

- Focal Lens:

The focal length influences the performance of the lens when engraving and marking materials. Smaller spot size laser beams guarantee greater power concentration as well as good cutting precision. Shorter focal lenses have been known to achieve tighter beam convergence which translates to sharp striking on complex designs.

- Software Interface:

Operators interact with advanced laser engraving machines using intuitive software for design uploads, parameter modifications, and control executions. These applications frequently encompass various file types such as DXF, AI, and SVG, guaranteeing congruity between the machine and user’s expectations. Optimal results coupled with minimal operational delays are a function of software calibration and accuracy as automation has enhanced efficiency.

- Cooling System:

To maintain the laser source and other components at the optimal operational temperature, effective cooling systems such as air or water cooling are employed. The prevention of overheating preserves the system’s performance and longevity. The industrial engravers have integrated cooling technologies and balanced energy consumption and operating performance to meet environmental sustainability goals.

- Machine Frame and Build Quality:

The build quality of the engraver, along with its frame, determines its operational stability and structural rigidity. High-grade construction and use of additional damping elements lower operational vibrations to ensure uniform marking repeatability at higher working speeds.

Through refinement of these components, industry leaders are redefining LASER engraving technology with maximum operational speed, unparalleled precision, and unprecedented versatility.

Differentiations Between Engraving and Cutting with a Laser

The main difference between laser cutting and engraving is their intended purpose along with how deeply they interact with the material. In my laser engraving sample, it seems clearer that laser cutting aims to completely separate a material into parts or shapes while engraving seems to simply etch a design or write on a surface. Both methods demand precision, but are employed differently depending on the end goal.

What Are the Applications of Laser Marking?

The process of laser marking has almost endless uses in countless fields. Permanent marks on products, such as serial numbers, barcodes, logos, and part numbers which allow the product to be traced and identified correctly are created using lasers. Automobiles, Aerospace, Electronics, and Medical devices industries use laser marking because of its accuracy and durability. Jewelry and other consumer goods also use laser marking to brand them or to add custom designs.

The Evolution and Components of Laser Marking Within Today’s Manufacturing

The accuracy, speed and cost efficacy of laser marking guarantees it’s implementation as a process within the modern manufacturing sector. As per the statistics of the industry, the global laser marking market is projected to increase its value from $3 billion in 2022 to approximately $7 billion in 2030. This boom in market value is expected due to the increase in product ID QDI or quality demand indicator, compliance requirements, and anti-counterfeiting policies.

Laser marking systems sustain a laser marking minimum material cost which provides a sustainable option for manufacturers. There is also a broad range of materials with the use of the technology such as metals, plastics, ceramics, and glass which is another plus for its support in multiple applications. An example of this is the automotive sector where laser marking has been adopted for the VIN codes and component tracking to ensure product traceability throughout the supply chain. The electronics sector also adopts the use of lasers for creating intricate markings on tiny components such as circuit boards and semiconductors which is impossible to achieve with conventional methods.

Further, laser technology has enhanced efficiency and versatility with advanced laser types like fiber and CO2 lasers. For instance, fiber lasers are more reliable and low-maintenance as they outperform older systems in speed. These technological advancements provide a favorable operating cost coupled with improved quality, thus offering a significant ROI.

Incorporating laser marking systems within the production lines has allowed for streamlined procedures, increased automation, and greatly enhanced company productivity. Such advantages prove the increasing significance of laser marking technology essential in today’s manufacturing workflows.

The Change of Product Manufacturing Through Lasers

Laser technology has fundamentally changed the manufacturing processes of consumer products by providing businesses with flexibility, efficiency, and precision due to advanced marking capabilities. This is critical as businesses pursue alignment with industry compliance regulations, internal branding standards, and product traceability. Laser application on consumer items like electronics and packaged goods is common to mark serial numbers, barcodes, and logos.

The most recent research suggests that laser marking systems have high accuracy, precision, and low material waste, resulting in lower overhead costs for manufacturers. Studies show that companies adopting these technologies have experienced up to 30% increases in productivity thanks to automation and speed brought by the systems. This further enhances workflows and bolsters uniformity in quality during massive production cycles.

Also, newer innovations in laser technology, such as fiber and CO2 lasers, now make it possible to mark on metals, plastics, glass, and ceramics. For example, fiber lasers are widely used for silicon wafer engraving in the electronics industry and CO2 lasers mark organic materials like wood or paper. These characteristics are what make lasers so popular for all types of manufacturing for different industries.

Aside from the operational advantages, laser marking has positive implications on sustainability initiatives. Traditional methods usually use inks or other chemicals which makes laser marking a greener and ecofriendly alternative as it does not release any harmful substances or requires any consumables. With the increasing focus on corporate responsibility, these systems help achieve the desired environmental outcomes while improving operational efficiency.

Newest Innovations In Processing Technology Using Lasers

The ongoing development in laser processing has broadened its scope and improved its efficiency in several areas. A good example is the modern fiber lasers, which have more powerful peak and beam power. Modern fiber laser systems are reported to mark up to several meters per second, which improves the production throughput with excellent marking quality.

The AI and machine learning tools allow manufacturers to change the parameters that the AI sets automatically, thus guaranteeing optimal outcomes during high-capacity production. Also, more advanced control software allows the laser marking process to be customized and automated. As per the latest market report, the laser marking market is expected to increase its volume at a CAGR of approximately 7.2 percent from 2023 to 2030, primarily due to increased adoption of this technology in the automotive, electronics, and medical device industries.

As a result of these modifications, laser systems are currently achieving unmatched precision which minimizes waste and errors. Together with their eco-friendly attributes, these factors make laser processing technologies indispensable tools in the contemporary manufacturing environment.

How to Select the Right Laser Marking Machine?

Make sure to take into account the following when laser marking a workpiece to ensure proper selection of the marking machine.

- Compatibility with Materials Used: The machine must be capable of accurately marking the materials you make use of, be it metals, plastic, or ceramics.

- Marking Accuracy: The sharpness and detail an inscription gives must meet the expectations of the present marking needs, thus must be checked prior.

- Machine Speeds: The particular piece of equipment needs to be selected according to the desired output and speed of work, thus productivity rate must be taken into account.

- Machine Category: Based on intended purpose, one must choose between CO2, fiber or UV laser machines.

- Software and Work Processes Integration: Look for a machine equipped with modern, intuitive software that enables full integration with existing processes and better meets your operational needs.

To better suit your operational needs, make sure to follow these suggestions to identify the correct machine.

Features to Look for in a Laser Marker

- Material Compatibility- Check that the machine works with the substrates you want to mark such as metal, plastic or glass.

- Primary Tasks- Determine the depth of marking, the time it will take, and the overall quality of the work to be done.

- Power Output- The complexity and type of marking tasks will determine the level of power output selected.

- User Friendly- Software should be simple in design and the machine easy to operate.

- Price- Look at the price of the device against its expected long-term value and the cost of servicing it.

- Customer Support and Warranty- Check if proper guidance, instruction, and guarantees are provided by the producers.

Analyzing Fiber, CO2, and UV Laser Machines

Fiber Lasers

- Perfect for etching onto plastics and metals and for easier marking on some ceramics.

- Fastest and most accurate on hard materials.

- Prevalent in marking and engraving metals.

CO2 Lasers

- Most suitable for wood, glass, leather and acrylic.

- Usually associated with engraving and cutting soft materials.

UV Lasers

- Ultra-sharp marking and etching are possible on fragile items such as glass and plastics plus medical devices.

- Heats up the surface very little leading to less harm on the soft surfaces.

Considerations for Deciding on Laser Power and Mark Speed

Marking procedures efficiency and quality depend greatly on the laser power and marking speed. High laser power is especially useful in applications where a large number of material pieces must be processed or when working with thicker materials. For example, the engraving speed on metals with a 50W fiber laser is significantly higher than that of a 20W fiber laser, and both lasers maintain engraving accuracy.

Lower power lasers, however, can be used on more delicate materials. These include fine engravings on jewelry or marking on soft plastics. When executing engravings or markings, having the appropriate power and speed is essential to minimize warping and discoloration, which is damage materials might suffer when subjected to excessive heat.

Power and speed settings can be adjusted according to the types of materials and required applications, which is why modern laser systems are often equipped with these features. Recent studies suggest that these advancements from other fields of study that focus on technology have altered the way laser’s resources are utilized by operating lasers quicker without losing precision and eco-friendly sustainability—critical for industrial and environmental settings.

What Are the Advancements in Laser Marking Technology?

The newest development in laser marking technology is the accuracy and speed of marking on different types of materials. Modern systems include automation like real-time monitoring and corrections which guarantees quality. Besides, lower power consumption has improved efficiency and made laser marking greener. As a result, this technology is used in manufacturing, healthcare, electronics, and many other industries.

Accuracy and Quickness Boosts in Laser Marking

The latest developments in laser marking technology have increased precision and operational speed to new levels with the rest of the industry closely following. The use of high-frequency lasers allows for greater beam modulation which leads to delicate tasks being accomplished with far more accuracy. Femtosecond lasers, which emit pulses in the range of 10⁻¹⁵ seconds, greatly reduce heat zones which assists in preserving the material and construction of the device. In electronic devices, medical instruments, and intricate designs on small surfaces, ultrasound helps prevent material distortion.

Moreover, results from the 2023 market analysis report suggest modern fiber laser systems in particular surpass marking speeds of 7000 mm/s in some applications. This assists augmenting production cycles by up to 50% when compared to older technologies. This unprecedented increase in speed still maintains quality due to dynamic beam shaping which guarantees repetition even on difficult materials such as reflective metals or composites.

Industrial smart automation and AI laser systems have streamlined processes with real-time feedback systems which optimize laser guidelines to provide maximum efficiency. As these methods enhance productivity, they also ensure sustainability by optimizing power consumption and minimizing material waste. In today’s environment-conscious manufacturing world, waste reduction is a critical concern.

Advancements in Laser Marking Technology

Recent innovations in laser marking and engraving are industrializing processes at an ever increasing pace. An example of this is the new capabilities of high-power fiber lasers, which can now perform hyper-marking at high speeds while maintaining exceptional accuracy. This advancement boosts productivity in the automotive, aerospace, and electronic industries. As recent reports indicate, modern fiber lasers have the ability to pulsate beyond 4 Mhb. This enables exceptional scalability when marking complex designs or large quantities of products.

One notable development is the ultra-short pulse (USP) lasers, which have better control of heat-affected zones of the material being engraved. This thermal anti-damage makes these lasers ideal for more sensitive materials like polymers, brittle ceramics, or semiconductors. In addition, there is now a greater need for high-resolution marking through QR codes or traceability marking. Some industrial laser systems are capable of creating markings as small as 25 microns wide, ensuring flawless readability even on tiny surfaces.

In addition, the efficiency of lasers has improved remarkably in the last ten years. With current systems easily achieving over 40% wall-plug efficiency, businesses reduce operational costs and energy spend—imperative elements for enterprises aiming for sustainable manufacturing dealing in eco-friendly solutions. The worldwide market for laser marking is expected to increase at a compound annual growth rate (CAGR) of 8.9% during the period of 2023-2030, further supporting the adoption of modern laser technologies in the new emerging markets. These advancements demonstrate how laser marking is not only more adaptable, but also more environmentally sustainable than conventional methods.

Impact of Laser Technology on Various Industries

Laser technology has profoundly changed multiple industries by providing contactless and efficient ways to mark, cut, and engrave with high precision. For instance, within the automotive industry, laser marking is used for the engraving of QR codes, serial numbers, and barcodes on critical parts for track and trace capabilities within the supply chain. Recent research shows that employing laser marking in automotive production has enhanced production precision by 15% while defect rates plummeted.

The electronics sector also derives advantages from laser marking, which engraves complex designs onto small parts like circuit boards and semiconductors. Industry surveys indicate that the Asia-Pacific laser marking market, fueled by demand for consumer electronics, surpasses 40% of the total share. Moreover, surgical instruments such as implants and other devices can now be traced to their manufacturers using lasers, which have become essential in maintaining regulatory requirements in the medical field, to marking manufacturers while ensuring material integrity.

The use of fiber lasers, in particular, has surged due to higher efficiency and lower maintenance costs. For example, fiber lasers make up about 60% of laser marking machines because of their ability to work with many materials including metals, plastics, ceramics, and even glass. Also, manufacturers can now increase production without limit due to improved control laser marking software which boosts marking speed by as much as 10% with no loss of quality.

Along with the innovations provided by all these industries, the facts are reason enough to use lasers as tools for faster production while maintaining the needed standards that modern businesses expect.

Reference sources

- Laser Marking Methods:

- Key Findings: This study systematizes various laser marking methods, emphasizing their adaptability to different materials and production needs. It highlights the importance of selecting the appropriate laser type based on material properties, marking type, and production requirements.

- Methodology: The research involved analyzing different laser marking techniques and their applications across various materials, creating a database to aid manufacturers in choosing the right method for specific needs.

- Laser Marking (Handbook of Laser Technology and Applications):

- Key Findings: The chapter discusses the advantages of laser marking, such as indelibility and reliability, compared to traditional methods like ink marking. It also explores the role of laser energy absorption in achieving high-quality, cosmetically appealing marks.

- Methodology: The study focuses on the interaction between laser energy and material surfaces, particularly polymers, to optimize marking quality.

- Top Color Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the 3 most common types of laser marking?

A: The three most common types of laser marking are fiber laser marking, CO2 laser marking, and UV laser marking. These types differ in their application and materials for laser marking.

Q: How do different types of lasers used in marking differ?

A: The variations between different types of lasers used for marking lie mostly in their wavelength and power level. These aspects determine the particular materials and processes to which the laser will be applicable. For example, fiber laser marking machines work with metals, whereas, CO2 lasers cut organic materials like wood and leather best.

Q: What is a fiber laser marking machine and its advantages?

A: A fiber laser marking machine utilizes a solid-state laser to make markings which is It’s efficient and produces permanent signs. It enables high speed marking. Its main advantages are: low maintenance, and the ability to mark metals and plastics, and do so effectively.

Q: Can you explain the role of a YAG laser in marking?

A: YAG laser is a type of solid state laser that is versatile with marking, engraving, and cutting of metals and some plastics. It is highly regarded for its extreme precision and power.

Q: What distinguishes a diode laser from a MOPA laser?

A: A diode laser is inexpensive and is typically employed for marking plastics and organic materials, whereas a MOPA laser (Master Oscillator Power Amplifier) provides greater versatility due to its adjustable pulse durations making it suitable for both light and dark marking on metals and plastics.

Q: What factors do I need to consider in choosing the laser marking machine appropriate for my applications?

A: Choosing a laser marking machine requires evaluation of the materials you intend to mark, the speed and precision requirements, and, of course, the budget allocated for the machine. You can purchase a guide to laser marking for more information on different types of laser machines as well as their uses.

Q: What are some widely used laser marking systems offered in the market?

A: Some of the most common laser marking solutions are fiber laser marking for metals and plastics, CO2 laser engraving for organic materials, and UV laser marking for materials sensitive to heat. These solutions are designed for particular types of laser marking processes and materials.

Q: How do different marking technologies apply to laser marking?

A: Different marking technologies make use of solid-state (fiber, YAG) and gas (CO2, UV) lasers for marking. The choice is based on the materials being worked on and the marking to be done, whether it is engraving or surface marking.