Elevate your woodworking projects easily and efficiently. A 4×8 CNC router machine might be just what you are looking for. Getting the right CNC router tailored to your needs can make complex work easier, reduce the time needed, and greatly enhance the quality of your work, whether you’re a professional or a passionate hobbyist. This article is meant to assist you in finding some of the best 4×8 CNC router machines and their key features, benefits, and suitability for different woodworking tasks. You’re bound to walk away from this piece with all the information necessary to make an informed decision that will elevate your craft.

What is a 4×8 CNC Router and How Does It Work?

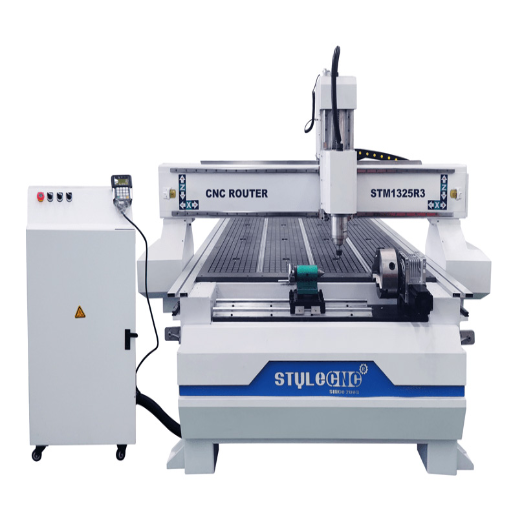

A CNC router of 4×8 dimensions is a computer-operated machine that performs cutting actions on a 4-foot by 8-foot work area. This router is useful for processing large materials such as plywood and acrylic sheets. They operate using instructions created from CAD files, which drive the device precisely. Various tools are used to carve, cut, and engrave materials to ensure precision and uniformity in engineering tasks. Automating repetitive tasks greatly reduces the amount of manual labor needed, which is particularly efficient for experts in woodworking, sign making, and other businesses that need precise work done repeatedly.

Key Features of a 4×8 CNC Router Machine

- Incredible Working Space

This 4×8 CNC router further offers a generous cutting area of 48″ x 96″ (4 feet by 8 feet), making it suitable for full-sized sheets of plywood, MDF, and other materials. Thus, it minimizes the need to resize and facilitates larger projects.

- Incredible Precision

This machine is equipped with advanced servo motors and ball screw drive systems, which enable cutting and engraving with tolerances as low as ±0.001 inches, ensuring professional-quality performance.

- Strong Construction

This machine is built with steel or aluminum frames, which protect it from extreme stability and durability shocks. Its robust construction minimizes vibrations, guaranteeing dependable performance and reproducible results even during extended periods of use.

- Compatible With Many Tools

The 4×8 CNC router accommodates cutting tools, including straight, angled, and specialized bits. This capability allows the router to cut, carve, engrave, and even drill into wood, plastic, foam, and select metals.

- Easy Software Integration

This machine works easily with CAD/CAM integrated software, which allows the user to design and create in a simple, straightforward manner. It also accepts commands in G-code, increasing its usability to novices and experts alike.

How to Set Up Your CNC Machine

Step 1: Arranging and Setting Up Components

As per the manual, check that every part of the CNC machine is packed securely. You should set the machine on a flat, firm counter that can handle its weight and the vibration produced during operation. An industrial-grade work desk or table is recommended.

Step 2: Checking Power Supply

Confirm the power supply requirements of your CNC machine. Most models work with 110V or 220V. Make sure you have a power outlet available in the working area. For your setup, ensure the grounded outlet configuration is up to standard to avoid electrical issues, and use surge protection to prevent any electronic damage caused by voltage spikes.

Step 3: Fixing Parts Together

Fix the parts by connecting motors, placing end stops, and attaching gantries as per the manual. Most new CNC machines come pre-assembled, cutting down the time needed for setup. Smaller CNC machines usually require an hour or two for assembly, whereas larger units take longer. Be sure to work with the provided tools to mitigate the chance of component damage during assembly.

Step 4: Installing the Software

Consider downloading and installing design software like Fusion 360, Autodesk, or Easel. These applications will help generate G-code formatted toolpaths. Depending on the machine, connect it to the computer using a USB or Ethernet cable. Install the driver software and check that it is up to date.

Step 5: Calibration

Ensure that the CNC machine is calibrated for measurement precision for every operation. The provided tools should be applied in the setting for the X, Y, and Z axes. Confirm that the trim tool or spindle is correctly positioned and check the jog movement in the machine software. Verify parts movement, belt/lead screw tightness, and any other movement friction issues.

Step 6: Securing Materials

Identify the material for the main work and set the parameters for the first cut. The material being worked on must be firmly attached to the machine work bed through a work clamp or vacuum attachment. The part must be flat and rigidly secured to prevent any unwanted movement during the operation.### Step 7: Carrying Out a Test Run

Start with a test design as a straight-edge check. Consider running a square or static circle, and while programming, set the spindle speed and feed rate to low. During the procedure, monitor the cutting depth, spindle level, and material surface for potential noise and erroneous traces of defect finishing.

Step 8: Safety Measures

You should always wear the right protective equipment, such as goggles, gloves, and ear defenders. Make sure that the working area is free of obstructions and observe all safety measures printed in the manual. It is not allowed to walk away from the machine that is working; in case of unexpected events or defects, you have to be there immediately.

These steps will ensure that your machine is optimally configured. This will allow you to approach CNC machining with confidence and achieve outstanding precision and quality in your projects.

What Are the Benefits of Using a 4×8 CNC Router?

A few key features make the 4×8 CNC router an undeniable asset to any project.

- Huge Working Space: The 4×8 size easily fits big materials, such as a whole plywood sheet. This makes it extremely useful for furniture, signage, and other hefty projects.

- Accuracy: Automated routers maintain consistency throughout the process, guaranteeing accuracy in the results with complex designs.

- – Automation: These devices operate much faster than humans, allowing them to beat manual working methods and reduce the time it takes to create products.

- Product Variety: A 4×8 CNC Router can be used with a wide array of products, working effortlessly with wood, plastic, and even metal.

- Long-Term Savings: The amount of material wasted is decreased, along with the speed of production, which can save money in the long run.

The 4×8 CNC Router has brought ease and creativity into the hands of freelancers and companies.

Efficiency in Woodworking

The productivity of woodworking with a 4×8 CNC router is unparalleled, as it combines accuracy, speed, and flexibility towards achieving an outstanding outcome. The most updated search data reveals that one of the most sought-after queries is how these machines enhance workflow compared to other traditional forms. A 4×8 CNC router enhances a process by automating complex shapes and designs, thus ensuring tight accuracy with minimal human interaction. This removes repetitive work and monotonous production processes, saving a lot of time. In addition, a 4×8 CNC router is well-suited for mass production and custom production owing to its exceptional capabilities in dealing with monotonous tasks. With the help of new computer software, woodworkers and carpenters can quickly respond to market trends and expectations, thus improving their creativity and output.

Precision and Accuracy in Routing

Implementing modern-day technology has made routing accuracy and precision remarkably better. Woodworkers can now accomplish exacting precision, up to the micron level, with cuts and designs on wood using CNC (Computer Numerical Control) routing systems. Attention from Google search shows rising searches for automated routing technologies with zest for “Improving woodworking precision” and “Accurate CNC Software”. This indicates that the woodworking and construction industry is beginning to understand the use of technology in minimizing human mistakes, precision in material usage, and maximizing efficiency. Modernised routing, hand in hand with advanced machinery and user-friendly software, accomplishes what was otherwise impossible with traditional methods, reinforcing its role in the craftsmanship and industrial use of woodworking.

Versatility for Different Materials like Plywood and MDF

CNC routers can cut wood, MDF, and similar materials with an excellent level of accuracy while offering a clean finish for various tasks.

| Parameter | Plywood | MDF |

|---|---|---|

|

Cut Quality |

Smooth, precise |

Clean, no splinters |

|

Durability |

Strong, layered |

Stable, dense |

|

Applications |

Furniture, panels |

Engravings, carvings |

|

Cost |

Moderate |

Economical |

|

Finish |

Paintable, stainable |

Paintable, varnishable |

What Should You Consider When Buying a 4×8 CNC Router?

When purchasing a 4×8 CNC Router, pay attention to these details:

- Precision and Accuracy – Check whether the router can make quality and precise cuts. Check repeatability and tolerance for routers to ensure the router will work for you.

- Build Quality – Business owners should focus on the quality of the frame. A sturdy frame guarantees stability and better performance over a long period.

- Software Compatibility – The machine should be compatible with easy-to-obtain design software.

- Motor and Power—Determine the motor’s power to ensure it can work with your preferred materials, such as wood and plastics.

- Work Area—Confirm that the size will fit your project. The 4×8 indicates the machine’s working dimensions.

- Cost and Value for Money—Weigh the initial cost against the router’s features, maintenance, and overall cost. Choose a router that offers the best value within your budget.

- Support and Warranty – Good customer care support and warranties are essential for addressing any possible issues.

Taking all of these factors into account will permit you to make the best selection of a 4×8 CNC router for your needs.

Budget-Friendly Options: Finding an Affordable CNC Router

Carefully selecting an inexpensive CNC router requires finding a balanced blend of cost and functionality. Currently, some makes and models appear to be booming in the market. For example, Bob’s CNC Evolution 4 comes at a reasonable price. It is perfect for new users and small businesses due to its sturdy structure of laser-cut wood and compatibility with almost every software. Moreover, it comes highly recommended. Another economical option is the Genmitsu 3018-PRO, famous for its compact design and easy assembly for smaller projects. As its name suggests, it is made for 3018 millimeters, making it a great fit for rusted designs.

Slightly bigger and advanced models on a budget, such as Shapeoko 4, also make a case for the combination of quality and cheap prices. However, these routers might not offer as many functions, so evaluate them. When assessing the numbers, do not forget to look at the dimensions of the work area, the support materials provided with the router, the user manual, and the overall construction of the machine. Also, certified used or refurbished CNC routers can be a game changer when it comes to saving money, provided they are obtained from trustworthy sources that sell them at reliable prices. It is mandatory to check the support materials, such as customer reviews and warranty pamphlets. Let’s not forget the main attraction, terms, and conditions for purchasing a low-priced CNC router while still getting the best bang for your buck.

Choosing Between ATC CNC, and Non-ATC Models

When selecting between ATC ACNC (Automatic Tool Change) and non-ATC models, it is important to analyze your unique budget, needs, and production. An obvious advantage of ATC CNC routers is the automated tool-changing feature, which greatly benefits projects with complex designs and frequent tool-change requirements. This feature enhances efficiency tremendously, making it a good option for high-volume production or professional workshops.

In contrast, non-ATC CNC models are more straightforward to operate, which translates to being more economical. They are ideal for small-scale projects, minimal tool-changing demands, or hobbyists. Although it still provides dependable results, increased time is required due to the manual tool change intervention.

As indicated by Google search trends, ATC machines are targeted towards professionals who require cost-effective and time-saving features. However, non-ATC models are well-received by budget-savvy users and newcomers to CNC machining. In the end, it all depends on the complexity and scale of your project, as well as the budget allocated for saving features.

Evaluating the Best CNC Machine for Your Needs

With Google search trends in mind, your needs when choosing a CNC machine must include a variety of factors. First and foremost, determine what type of projects you will be handling—complex and large-scale, or smaller and simpler? ATC (Automatic Tool Changer) machines are very popular for commercial purposes because of their time-saving capabilities. They are the most efficient option for professional users. However, non-ATC models remain a strong contender for budget-focused beginners. Google Trends also shows increasing attention to multifunctional economic machines, emphasizing the mid-line cost and operational value balance. In the end, the best CNC machine is the one that fulfills all your demands concerning skills, types of projects, budget, and offers productivity and value for money.

Where Can You Find the Best CNC Router for Sale?

Searching for the most suitable CNC router on the market should begin with reputable retailers and manufacturers with reliable equipment. Retailers like Amazon, CNC Router Store, and Inventables cater to different needs and budgets. Also, popular brands like Bob’s CNC, Axiom Precision, and Shapeoko have online shops with detailed descriptions and multiple reviews, which can be very informative. Sites like eBay can also prove helpful for people looking for cheaper or second-hand items. Don’t forget to check that the seller has a good reputation and offers some form of warranty or customer service that would ensure a reliable purchase.

Top Retailers for CNC Machines

Using Google and other search engines can be helpful when looking for specific CNC machine retailers. Shoppers looking for reviews and competitive pricing continue to gravitate towards Amazon and its extensive range of entry-level to professional-grade CNF machines. Furthermore, Inventables continues to guide customers along their freshly minted hobbyist CNC machines, like the X-Carve, with insightful instructions for Tommy’s starting. Carbide 3D attracts customers with its reliable user guidance and Shapeoko’s tough characteristics, cementing its status as a recurring favorite among small business owners and DIY solutioners. For their precision and steadfast dependability, Axiom Precision and Laguna Tools are often regarded as the best in the business, providing expert-grade goods, CNC machines, and frequently appearing on search radar. Grizzly Industrial also falls into this category, servicing larger industrial customers alongside smaller enterprises. A Google search would provide an accurate comparison and review to help determine the most appropriate retailer for the client’s needs and budget, ensuring a reliable buy.

Online Marketplaces for 4×8 CNC Router Deals

When searching for the best prices on a 4×8 CNC router, online shopping sites like eBay or Amazon have listings to meet every budget. Sellers from around the globe often list refurbished machines, which makes Amazon and eBay appealing for bargain shoppers.

Unlike eBay and Amazon, platforms like Woodworking Network Classifieds or MachineryTrader are tailored for professionals looking to buy high-end, meticulously crafted woodworking tools and equipment.

According to Google’s most recent search data, these resellers are well known to frequently showcase tools and equipment from reputable manufacturers, classifying them as trustworthy resources. Shoppers who value reviews and product descriptions can turn to Alibaba and Made-in-China, as they provide direct access to manufacturers. Exploring multiple auction sites simultaneously ensures customers get the best offers for their money, but off-lookup is not added to performance metrics. Always check the warranty and seller ratings before making the purchase to avoid buyer’s remorse.

Comparing Prices: New vs. Used CNC Routers

Unlike purchasing used CNC routers, which might save money but come without a warranty and demand constant upkeep, new CNC routers feature the latest technology, require considerably less maintenance, and come fully backed by a warranty.

| Parameter | New | Used |

|---|---|---|

|

Price Range |

$7,000 – $200,000+ |

$2,000 – $90,000 |

|

Warranty |

Included |

Limited or none |

|

Technology |

Latest |

May need upgrades |

|

Maintenance |

Lower |

Higher |

|

Initial Cost |

High |

Low |

Reference Sources

- Freeform Surface Fabrication Method with 2D Cutting

This paper explores the application of CNC routers for standard 4×8 sheet cutting in intricate geometrical designs. - Heavy Timber Buckling-Restrained-Braces

This work discusses CNC routers for timber groove cutting and their uses in construction. - (In) forming: the affordances of digital fabrication in architectural education

- Top CNC Router Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a 4×8 CNC router?

A: A 4×8 CNC router is a machine designed for cutting and engraving a variety of materials, including soft wood. Its working area is 4 feet by 8 feet. It is commonly used in woodworking, cabinet, and door making applications.

Q: What related products should I consider when purchasing a 4×8 CNC router?

A: When purchasing a 4×8 CNC router, you may want to consider related products such as a vacuum table, vacuum pump, dust collector, and a control box to enhance the functionality and efficiency of your CNC routing tasks.

Q: Can I use a 4×8 CNC router for wood carving?

A: A 4×8 CNC router is ideal for wood carving, including relief carving and cabinet door production. The CNC wood router can handle various designs and intricacies in soft wood and other materials.

Q: Are there any specific features to look for in a 4×8 CNC router machine for sale?

A: When looking for a 4×8 CNC router machine for sale, consider features such as industrial strength, a reliable controller, hiwin linear guides for precision movement, and compatibility with a vacuum adsorption system for secure material handling.

Q: What technical support is available for a 4×8 CNC router?

A: Most manufacturers offer technical support, including help setting up, operating, and troubleshooting CNC routers. It’s essential to check customer service availability and resources before purchasing.

Q: How does a vacuum table enhance the performance of a CNC router?

A: A vacuum table provides a secure hold on materials using vacuum adsorption during the CNC routing process. This keeps the material in place, reducing the risk of movement and ensuring precision cuts, especially with soft wood and other delicate materials.

Q: What types of materials can be processed with a 4×8 CNC router?

A: A 4×8 CNC router can process a variety of materials, including soft wood, hard wood, plastics, and some metals, depending on the machine’s specific capabilities and the tooling used.

Q: What is the significance of a dust collector in a CNC router setup?

A: A dust collector is essential in a CNC router setup to maintain a clean working environment. It removes debris and dust generated during cutting processes, helping improve air quality and protecting the machine from dust accumulation.

Q: What is the price range for a 4×8 CNC router?

A: The price range for a 4×8 CNC router can vary significantly based on features and specifications but typically starts from a few thousand dollars and can go up to tens of thousands for industrial-grade models. It’s best to request a price quote from manufacturers or suppliers.

- Best Metal CNC Router: Precision Cutting & Engraving Machine

- The Ultimate Guide: Desktop Fiber Laser Marking machine

- Understanding the Melting Point of Glass: A Comprehensive Guide

- Continuous vs Pulsed Laser Cleaning: How to Choose the Right Machine

- Understanding the Melting Point of Silver: A Precious Metal Insight

- Best Beginner CNC Router: Choosing Your First CNC Machine

- The Unmatched Tungsten: Exploring the Melting Point of the Metal with the Highest Melting Point

- The Ultimate Guide to Laser Cleaning: How This Revolutionary Rust Removal Technology Works