With the introduction of 3D UV laser marking machines, industries have a new level of precision and efficiency. Whether manufacturing, electronics, medical devices, or any other industry that requires intricate engraving or marking, understanding these advanced technologies is essential. This article will explore the intricacies of 3D UV laser marking, its unmatched advantages, and how it differs from other techniques. With comprehensive explanations of the mechanisms and powerful insights into industry specifics, this article aims to enable businesses to make the most of these advanced technologies. So, if precision and sustainability are on your agenda, look no further. Keep reading to learn some essential details that could improve your workflow.

What is a 3D UV Laser Marking Machine?

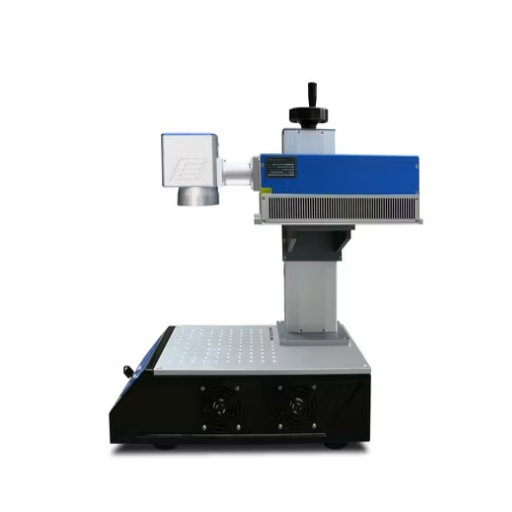

A 3D UV Laser Marking Machine is used to accomplish accurate and everlasting marks on different materials with the help of an advanced device. This method of engraving or etching surfaces uses ultraviolet laser technology, which does not inflict considerable damage or melting due to heat. Unlike other marking methods, this machine is designed with the capability to mark intricate shapes, rough surfaces, and assorted textures with a high level of precision. It is particularly advantageous for electronics, medical devices, and aerospace industries due to its accuracy and flexibility.

How does a UV laser marking machine work?

A laser marking machine that utilizes a UV laser concentrates a laser beam on an object’s surface. The applied laser works with a frequency of approximately 355 nanometers, allowing it to micrometer-work on materials with breathtaking precision on a micrometer scale. This accomplishes falls under ‘cold processing’, meaning the heat impact of the laser in question is almost inert, lower than the ‘blues’ threshold. There is no damage to the workpiece due to marks, blows, burns, or distortions with excessive thermal stress that pose a risk to sensitive components or materials prone to heat on the other hand.

This approach is beneficial for the ultra-modern technology of engraving complex patterns or small-scale serial numbers on slits of electronics, machinery, and even fine plastics tools used in the medical field. It also allows vapor marking of serial numbers engraved on glass or ceramics. Marking string materials is possible and done with minimal cracking or glass splitting. Marking string materials is also done with minimal thermal deformation.

In the industry, UV laser marking machines have a marking efficiency of 7000mm/s and a marking accuracy of ±0.001mm. This means they are handy for production lines that require speed and consistency. With the increase in technology, modern UV laser markers are being incorporated into automated systems, providing better efficiency in high-volume production processes. In addition, they are more energy-efficient than older models, which require more maintenance and have a shorter working lifespan.

What are the benefits of using a 3D laser marking machine?

- Meticulous Precision

Marking works on complex and uneven surfaces and objects can be performed with a High Precision 3D Laser Marking Machine with an accuracy of ±0.001mm, and guarantees precision on mark details and curvature.

- Flexibility On Different Materials

This machine’s versatility allows marking different materials, including metals, plastics, glass, ceramics, and so on. That flexibility can be utilized in various industries, such as medical, automotive, electronics, aerospace, etc.

- Optimum Speed and Efficiency

3D Laser Marking Machines are adaptable to high-speed production environments, thus significantly reducing the operation time. Their technology minimizes downtime,e which makes the machine ideal for large-scale manufacturing.

- Permanent Marks: Cost-Friendly

Marks made by the 3D marking machine are highly resistant to deformation, corrosion, and any form of dampness in harsh and extreme conditions, making them useful for industries that permanently need specific identification.

- Low Maintenance, Cost Effective

Compared to other marking methods, these machines require lower maintenance, which makes them cost-effective for businesses. Furthermore, they are energy efficient and have a long working lifespan, thus reducing operational costs.

What materials can a UV laser engraver mark?

| Material Type | Examples | Key Features | Notes |

|---|---|---|---|

|

Plastics |

Polycarbonate, PVC, ABS, Acrylic |

Precise marking, minimal heat impact |

Ideal for sensitive and intricate designs |

|

Metals |

Copper, Brass, Stainless Steel |

High contrast, detailed engraving |

Suitable for coated and reflective metals |

|

Glass |

Glass Bottles, Displays, Windows |

No cracks, high contrast |

Perfect for delicate glass surfaces |

|

Ceramics |

Tiles, Medical Equipment |

Durable marks, thermal resistance |

Withstands wear and exposure |

|

Organic Materials |

Wood, Leather, Paper |

Fine details, clean results |

Works on natural, heat-sensitive materials |

|

Silicone |

Medical Devices, Technical Equipment |

High contrast, soft material compatibility |

Requires precise settings |

|

Composite Materials |

Nonwoven Fabrics (PP/PE), MDF |

Smooth marking, less heat spread |

Ideal for masks and boards |

How to Choose the Right Laser Marking System?

While selecting any laser marking system, these features should always be kept in mind:

- Material Compatibility

Always ensure that the laser marking system you purchase is compatible with the materials you work with, such as metals, plastics, and glass.

- Marking Speed and Precision

Estimating speed and accuracy is essential for quality checking. Make sure the system meets your expectations and production requirements.

- Power and Wavelength

These two features are comprised of the laws of physics. Ensure the power level and wavelength are perfect for your specific marking needs.

- User Controls

Software and controls should be designed to be operated without complicated navigation schemes and intensive instruction intake.

- Durability and Reliability

Ensure the system is designed to endure long work hours under extreme conditions.

- Budget & Maintenance Costs

These will always remain most critical. When selecting, try to stay within the limit first, and think about operating costs later.

Use all these factors to configure a system that best fits you.

What should you consider when selecting a laser engraving machine?

A definition of a laser engraving machine will explain how an integrated printer-cutter device can be used with computers and can cut or engrave materials like wood, glass, metal, and more. A good laser engraving machine will serve you well in the coming years if accompanied by adequate research on features, options,

- precision, and speed.

Different laser machines can engrave different materials, such as wood, metal, glass, acrylic, and leather. Leather can be engraved with a strap laser, metal with a fiber laser, acrylics with a CO2 laser, and many more lasers. Fiber lasers are said to outdo CO2 lasers when it comes to engraving metal by 10 times. This would mean fiber lasers are best for industrial use, as their speed can prove to be essential.

The power of the laser also dictates the speed of the engraver. The power of the laser that cuts or engraves materials affects the level of polish and clarity of the engraving. With proper research, it can be proved that a fiber laser of 50 W can engrave stainless steel at a staggering 150 inches per minute. It doesn’t end there; additional power translates to 100 W, yielding even greater results without compromising speed.

- Carving Area and Other Specifications

Check the workspace or bed size of the laser engraving machine. Spaced-out machines like 20”x12” or 36”x24” have a larger area of engraving and offer much more versatility for larger projects. This is especially important for industrial-level operations or businesses that require designing custom products on a mass scale.

- Accuracy and Engraving Definition

The quality of precision engraving, in this case, the attention to detail granularity, is defined by the intricate details of its lasers. It is measured in DPI, dots per inch. Machines with a resolution of 1000 DPI or more are more suitable for complex designs like logos or delicate text.

- Usability and Efficiency

The balance between power and ease of use: Look for machines that operate on the cloud and have other basic software, like AI, to make the workflow much more efficient. Many modern systems have integrated with design software like Adobe Illustrator or CorelDRAW, which is user-friendly.

- Sturdiness and Efficiency of Cooling Devices

The sturdiness of the laser engraver machine is also tied to its longevity. Overheating remains one of the most common problems with laser devices, which is why our water cooling systems work best for efficient, durable builds.

- Budget and Return on Investment (ROI)

Basic models of machines can cost around $500 to $2,000, while professional-grade models can run anywhere from $5,000 to $50,000 or more. Consider operational efficiency and revenue potential for high-quality, fast engraving—advanced technologies can have improved ROI. For example, in a high-volume production setting, a professional-grade fiber laser engraver can yield back its value within months.

- Safety Features and Regulations

Check that the machine has appropriate safety features for FDA or CE compliance. Protective husks, ergonomic arms, and fume extraction systems can guard the operator from laser radiation and material fumes.

Considering all of these factors holistically enables you to select an engraving machine that strikes an ideal balance between performance, versatility, cost-effectiveness, and operational efficiency.

How does marking speed impact the choice of a laser marker?

The efficiency and productivity of a laser marking system greatly depend on marking speed. Marking speed is the maximum rate the laser can engrave or mark the intended material, measured in characters per second (cps). Higher speeds tend to improve marking efficiencies, which decreases production time, allowing manufacturers to supply products at a higher demand and scale operations.

High-speed laser markers benefit the automotive, electronics, and packaging industries, where time-critical production timelines are the norm. According to industry data, modernized fiber laser markers attain precision and clarity markings and achieve up to 1,000 cps speeds. This is useful for serial number, barcode, or logo engraving during assembly line production.

Regardless of the positive implications of marking speed, other factors need consideration. These include design complexity, construction material, and laser power. For example, marking on metals will necessitate a slower speed change to ensure deep, permanent markings. In contrast, slower speeds for intricate graphics may be essential to guarantee high resolution and accuracy.

Choosing a laser marker with the right speed necessitates a compromise between throughput and mark quality. Companies should reconsider their workflow demands and the materials to select a machine that meets objectives and does not obstruct efficiency or accuracy. Precision control over marking speed on an adaptable laser marker greatly enhances productivity by allowing users to switch between different tasks.

What are the differences between UV and CO2 laser marking systems?

| Parameter | UV Laser | CO2 Laser |

|---|---|---|

|

Wavelength |

355 nm |

10.6 micrometers |

|

Marking Process |

Cold marking, minimal heat stress |

Heat-based marking |

|

Material Compatibility |

Plastics, glass, and metals |

Organics, acrylic, some plastics |

|

Precision |

Ultra-fine, detailed |

Moderate |

|

Applications |

Electronics, medical, aerospace |

Woodwork, packaging, crafts |

|

Heat Effect |

Minimal damage |

Higher heat impact |

|

Cutting Ability |

Limited to thin films, PCBs |

Organics and plastics |

|

Cost |

Higher |

Lower |

|

Maintenance |

Long lifespan, minimal maintenance |

Frequent maintenance for gas replacement |

|

Strength of Metals |

Surface marking only |

Limited unless pre-treated |

Applications of 3D UV Laser Engraving

The advanced 3D UV laser technology is one of the most precise laser engraving methods used in many industries because of its adaptability. The main sectors are:

- Electronics – Engraving sophisticated designs on printed circuit boards (PCBs) and marking small electronic components.

- Medical – Marking medical instruments, implants, and devices with high precision where utmost accuracy is mandatory.

- Aerospace – Marking parts like identification and serial numbers on components without engraving into the material.

- Luxury Goods – Personalizing exquisite items such as watches and jewelry with precision logos and detailed marks.

- Automotive – Marking control panels and other pieces with appropriate identifiers and tracking numbers.

It is most useful in situations requiring great detail, permanent changes, and minimal thermal influence.

What industries benefit from UV laser technology?

Due to its ability to delicately process materials with precision, UV laser technology has vast applications in different industries due to its versatility and low thermal impact. Its application spans multiple industries. Below, find five sectors that benefit from this technology.

- Medical devices: Catheters, implants, and surgical instruments are marked with precision and UV sterile lasers. This assists in ensuring compliance due to traceability requirements. According to an industry report, the market for laser marking will exceed an annual growth rate of 8% for medical devices.

- Electronics: Most delicate components enable UV lasers to mark microchips, printed circuit boards, and PCBs, thus aiding the electronics industry. The expected value of the electronics industry in 2030 is 1 trillion dollars, and the growing electronics sector is the reason behind this demand.

- Pharmaceuticals: UV laser technology aids accuracy in marking drug packaging, labels, and anti-counterfeit codes. It also upholds safety and compliance with regulations. Based on research studies, concerns about counterfeiting are expected to lead to significant growth for the laser marking market in pharmaceuticals. Aerospace: In this field, UV lasers are used for high-accuracy marking vital components like turbine blades and control systems, which do not affect the material structure. The aerospace sector implements UV lasers considering their durability and safety concerns.

- Semiconductors: About lasers, UV technology scribing sustains a significant position in marking silicon and carrying out micro-setting precision in semiconductors. The growth of semiconductor industries, driven by AI and IoT technology development, increases the use of UV lasers.

These industries showcase the flexibility and precision of UV laser technology for high standards and trusted applications.

How is a 3D laser engraver used in product customization?

| Application | Description | Key Benefits | Examples |

|---|---|---|---|

|

Personalized Gifts |

Engraving custom designs or text |

Unique, sentimental items |

Wedding keepsakes, plaques |

|

Branding Products |

Adding logos to products |

Enhances brand visibility |

Pens, USB drives, drinkware |

|

Signage Creation |

Making detailed signs for display |

Standout, professional appearance |

Storefront signs, event banners |

|

Art and Decor |

Creating intricate 3D designs |

Eye-catching, adds depth |

3D wooden panels, ornaments |

|

Industrial Marking |

Marking details on parts or tools |

Traceability, precision |

Mechanical parts, equipment plates |

|

Jewelry Customization |

Producing detailed, unique designs |

Personalized, high-quality finishes |

Necklaces, rings, bracelets |

|

Product Prototyping |

Prototype designs with intricate details |

Fast, precise iterations |

Moldings, conceptual models |

|

Sub-Surface Designs |

Engraving inside transparent materials |

Creates floating visual effects |

Glass cubes, crystal awards |

|

Interactive Displays |

Complex, layered engravings for visuals |

Engaging, tactile designs |

Museum artifacts, educational tools |

|

Collaboration Projects |

Working with artists for new creations |

Expands audience reach |

Custom sculptures, intricate emblems |

What are typical marking applications for UV laser markers?

Because of their unparalleled marking quality that is not thermally damaging, UV laser markers are highly regarded throughout many industries. Here are five applications that make the best use of them:

- Electronics Components

UV laser markers are immensely popular for engraving multiple details on semiconductors, circuit boards, and microchips, including logos, QR codes, and serial numbers. The engraving is very intricate and detailed.

- Medical Devices

Imprinted tools and devices are highly utilized in the medical sector. They require markings of barcodes, batch numbers, and even expiry dates for scalps, surgical apparatus, and other medical implants. Using UV lasers guarantees precision and safety tests.

- Pharmaceutical Packaging

Marking in the pharmaceutical industry is equally important; blister packaging, labelling, and bottling all require attention to production code and the lot number. UV turns out to be perfect for anti-counterfeit stamping, as UV lasers mark those details, providing safety for buyers.

- Plastic and Polymer Products

Thermoplastic polymers and plastics are no longer a problem; automotive trim pieces, consumer electronic casings, and packaging have become easier. Those materials have the advantage of having marks left by UV light and offer unique branding due to the high precision во the laser.

- Glass and Ceramics

UV lasers are commonly used to engrave or etch meticulous designs on fragile materials, including glass and ceramics. Marking luxury items alongside bottles, mirrors, and fine ceramic wares is done without damaging the surface.

These applications prove the versatility and precision of UV laser markers across different industries, owing to their ability and effectiveness to be both clean and durable.

Advantages of Using UV Laser Technology

- High Precision

Marking with UV lasers can be done with extreme precision on small or intricate surfaces without inflicting a harmful effect.

- Versatility

They can be used in various materials such as plastic, glass, ceramics, and metals.

- Low Thermal Impact

The cold marking technique utilizes the least heat possible, ensuring the material stays intact.

- Durable Results

The markings are sharp, permanent, and skillfully resist erosion over time.

- Eco-Friendly

UV laser technology aids in reducing chemicals and minimizes waste. Thus, using it is an eco-friendly approach.

How does UV laser engraving offer damage-free marking?

The UV laser engraving method provides accurate marking with no damage to the surface due to its minimal thermal impact. This revolves around ultraviolet lasers having a broad wavelength of 355nm, which is easily absorbed by various materials, including glass, plastics, and metals. Unlike older systems that used to engrave using lasers that relied on heating surfaces, UV laser engraving uses cold marking, which removes thermal stress on the material to prevent cracks, damage, or surface deformation.

Thermal stress minimization in the engraving process allows for exceptional detail. It permits the creation of intricate patterns, barcodes, and text while spot diameters remain as small as 10–20 microns. Analysis demonstrates that the efficiency rate of clearly and legibly marked engravings using UV laser techniques is 99%, making it useful in the medical device, electronics, and automotive manufacturing industries.

Furthermore, the non-contact approach to engraving makes UV laser technology an optimal, damage-free solution for high-precision marking. Modern studies also state that defect rates are reduced up to 50% when comparing thermal engraving and UV engraving, and product quality and lifespan are enhanced while eroding any physical pressure on the surface.

What is the significance of the 355 nm wavelength in laser marking?

Ultraviolet (UV) light has a specific 355nm wavelength that distinguishes it and makes it particularly useful for laser marking applications. Here are five of its contributions towards marking technologies:

- Better marking accuracy

The increased UV light wavelength allows for a smaller spot size; this promotes detailed microscopic markings, a prerequisite in medical and electronic device manufacturing.

- Reduced processing temperature (Cold Processing)

Compared to other lasers, the UV laser operates at much lower heat levels; this allows for a ‘cold’ marking process that does not thermally damage sensitive materials and maintains the workpiece’s structural integrity.

- Increased absorption for different materials

Glass, plastics, and even ceramics possess high absorption rates for 355nm UV light; this makes marking more efficient and decreases the risk of material deformation.

- Reduced opacity

These materials can also be marked and engraved without loss high concealment, characteristic in some technologically advanced materials. Ensuring quality and brand consistency is standard practice, particularly in industrial applications.

- Wide Scope of Possibilities

The precision of 355 nm UV laser technology works with heat-sensitive components like thin films, PCBs, and more fragile polymers. The capability to operate with so many different types of materials dramatically increases the economic industries.

How does high precision enhance the engraving process?

High precision allows for achieving complex, detailed designs with exceptional accuracy and enhances the engraving process. This method guarantees precise and clean marks even on the softest materials, which is pivotal for maintaining high standards with minimal chances of mistakes or destruction. Such a level of precision also increases the effectiveness and uniformity of the process, which, in turn, makes it dependable and professionally streamlined.

Reference Sources

1. Experimental Research on 3D Ultraviolet Laser Precision Marking Processing Technology

- Authors: Haibing Xiao et al.

- Publication Date: March 27, 2018

- Journal: DEStech Transactions on Computer Science and Engineering

- Key Findings:

- This study investigates the complexities of 3D laser marking using ultraviolet (UV) lasers.

- It highlights that 3D UV laser marking offers higher precision than traditional infrared laser marking, especially for non-metallic materials.

- The research demonstrates that UV lasers can improve surface quality and detail in 3D applications.

- Methodology:

- The authors conducted experiments using a 3D UV laser test bench, focusing on non-metallic materials.

- They compared the results of UV laser marking with those of 1064 nm infrared laser marking, analyzing the precision and quality of the markings.

2. 3D Fiber Laser Marking Machine for Metal Curved Nonmetal: A Preliminary Study

- Authors: A. Elawar, S. Dahan

- Publication Date: August 1, 2018

- Journal: The Journal of Clinical and Aesthetic Dermatology

- Key Findings:

- This preliminary study explores the application of a 3D fiber laser marking machine on both metal and non-metal surfaces.

- The findings suggest that the machine can effectively mark complex curved surfaces, a significant advantage in various industrial applications.

- Methodology:

- The study involved experimental setups to test the marking capabilities on different materials, focusing on the machine’s adaptability to various surface geometries.

3. Top 3D Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a UV laser marking machine?

A: A UV laser marking machine is a laser marking and engraving device that uses a UV laser source to create high-precision markings on various materials, including metals and glass. It is known for its ability to perform fine marking and subsurface engraving.

Q: How does the optical system in a UV laser engraving machine work?

A: The optical system in a UV laser engraving machine directs the laser beam generated by the laser source through a series of lenses and mirrors, focusing it onto the marking head. This allows precise control of the laser spot size and position, crucial for high-quality marking effects.

Q: Can a UV laser marking machine engrave 3D designs?

A: A UV laser marking machine can perform 3D laser engraving. It can engrave 3D files into materials, creating detailed 3D engraving effects on surfaces, including crystal and glass materials.

Q: What is the difference between 2D and 3D laser engraving?

A: 2D laser engraving involves marking designs on a flat surface, while 3D laser engraving allows for depth and texture, creating more intricate designs. The 3D laser engraving machine can engrave curved surfaces and subsurface layers for enhanced effects.

Q: What materials can a UV laser marking machine process?

A: A UV laser marking machine can process various materials, including metals, plastics, glass, and ceramics. It is especially effective on sensitive materials that require fine marking without causing damage.

Q: What is rotary marking, and how is it used with UV laser marking machines?

A: Rotary marking involves using a rotary attachment to mark cylindrical objects. This technique is commonly used with UV laser marking machines to engrave designs around the entire surface of items such as bottles and tubes.

Q: What is the purpose of the marking head in a UV laser etching machine?

A: The marking head in a UV laser etching machine directs the focused laser beam onto the material surface. It plays a crucial role in determining the marking effect and precision of the engraving process.

Q: What is subsurface engraving, and how does it differ from surface engraving?

A: Subsurface engraving involves creating marks within the material, such as in crystal or glass, without affecting the surface. This technique provides a unique 3D visual effect that differs from traditional surface engraving, where the marks are made directly on the outer layer.

Q: What are UV laser etching machines used for?

A: UV laser etching machines are used for various applications, including creating intricate designs on glass materials, fine marking on metal components, and producing high-precision subsurface engravings for gifts and awards.

Q: How does a UV laser marking process compare to other laser marking methods?

A: The UV laser marking is less heat-intensive than other methods, such as CO2 or fiber laser marking. This cold laser approach minimizes thermal damage to sensitive materials, making it ideal for fine marking and detailed engraving tasks.

- The Ultimate Guide to Laser Engraving and Cutting Machines for Acrylic

- Unleashing the Potential of Color Laser Marking Machines

- The Ultimate Guide to Choosing Your Portable Handheld Laser Marking Machine for Metal

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide