With 3D laser cutting and engraving technology, there have been tremendous advancements in both the manufacturing as well as creative industries, achieving unmatched value, efficiency, effectiveness, ingenuity, and effectiveness. Be it an active industry participant, a prospective creator, or just someone curious about modern-day technology, the ability to leverage and appreciate the capabilities of laser technology is a must. In the following parts of the document, we shall explain the process and steps of operation of 3D laser printing and cutting, discussing the benefits and implications of the technology on bespoke designs to mass production. Prepare yourself to discover and realize how to unleash the capabilities of the modern laser technology in your undertakings.

What is a 3D Laser and How Does It Work?

A 3D laser is a modern tool using active light for engraving, cutting ,or shaping materials. Emitting high powered laster mask the material in accordance with a certain sample tier pattern enabling burns, melts or vaporization of materials. The results are governed by customized computer programs, optimizing every single operation. 3D lasers can work with metals, glass, and even plastic; hence aiding voernemts its use for everything ranging from complex patterns to full pace industrial production.

Understanding Laser Technology in 3D Applications

Although the laser world is not so old for some industries, it has indisputably changed industries like healthcare, aviation and mechanincs as adds uniquness to precision, efficiency and adaptability. Another major benefit of lasers for 3D solutions is its touchless approach toward substance alteration. A study suggests that use of lasers spans wide ranges. As a result, the global markst of laser processing is expectd to exceed 27 billion dollers by 2026 and will dominate the aerospcae, automotive, healthcare and electronics market.

Additive manufacturing, or 3D printing, is one of the most developed applications of 3D lasers. Systems like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) use high-powered lasers to melt layers of powder materials into complicated structures. These systems have helped manufacture strong yet lightweight components for medical implants and parts in aviation and automobiles. For example, parts made from titanium using DMLS are significantly catwalk wannabe precious metal replicas accepts rubies standards tight strippers unisub stringent strippers titanium DMLS waste impeccable trimming meeting industry standards standards critical industry slaughter waste while deeming obliterating.

Moreover, lasers are extensively used in 3D imaging and scanning technologies for accurate object and terrain mapping and modeling. Advanced 3D laser scanners like LiDAR systems are capable of capturing millions of data points every second, imaging far more complex and sophisticated scenescapes than entire mountains and jungles italicized capturing them with utmost clarity. In self-driving cars, urban development, precise archeological work, and even intricate blueprints and maps, LiDAR technology has proven highly useful and incredibly accurate, providing instant data within millimeters.

One of the newest developments is dual systems combining laser tech with AI to streamline intricate construction workflows. An example would be AI laser systems that adjust during the operation to material variances, optimizing speed and imperfections.

In summary, innovations in 3D solutions sustain augmented functionality and efficiency, unsolved modern problems, by constantly evolving with the demand of the society as its backbone.

The Importance of Laser Beams in 3D Technologies

The importance of beams is tremendous for the advancement of 3D technologies. This can be in regard to 3D Printing Processes, metrology and also manufacturing. The accuracy and the speed of the task being done make them extremely useful. An example includes 3D printing where laser beams help in melting or sintering materials. Such that complicated and detailed structures can be achieved. Methods like SLS and LPBF are dependent on the precision of laser beams to manufacture fast with perfectly shaped components with waste being at a negligible amount.

More and more new information received is supporting 3D manufacturing with the help of lasers. It has been reported that systems with lasers can achieve 20 micron precision all shifting the old ways greatly. In addition to this, use of laser technology has also increased tremendously in 3D metal printing with expectation on the rise. The report states that the global additive manufacturing market will increase rapidly at a 20.8 percent CAGR between 2023 and 2030, primarily due to development on laser systems.

In addition to production, laser metrology offers remarkable advantages in the realms of quality control and inspection. Currently, laser scanners have the capability of capturing up to two million data points within a single second and thus perform extraordinarily well in 3D model validation and prototype scanning. Moreover, with regard to sustainability, laser technologies classifi as sustainable alternatives since they minimize material waste due to their precise and reusable nature while also aligning with the global goal of cutting down resources consumption.

The integration of artificial intelligence and machine learning alongside lasers is expected to further advance their application within 3D processes. In particular, AI systems are capable of evaluating sensor data in real-time, enabling them to adjust laser power alongside the beam’s focus as necessary. This integration is bound to amplify precision, efficacy, and scalability across such a wide ranging spectrum from medical to aerospace devices.

The Advantages of 3D Laser Scanning

3D laser scanning is emerging as one of the most vital gateways toward transformation within different industries given its invaluable capability of providing quick, detailed measurements of objects and environments. Notably, the newest 3D scanners boast a staggering benchmark of capturing two million data points every second with an accuracy of 0.02 mm, making professionals’ lives easier when it comes to creating digital twins. This enables professionals in virtually every industry to improve design, construction, and quality control workflows.

The advantages of 3D laser scanning are broad and well understood. In the construction and architecture sectors, the technology aids in the development of Building Information Models (BIM), enhancing project workflows and diminishing errors. As reported by Google, firms that utilized laser scanning experienced a 30% improvement in revision accuracy during the design phase as compared to prior years. In manufacturing, the adoption of laser scanning technology for reverse engineering is on the rise as companies strive to build more accurate models and streamline the detection of production flaws.

Modern laser scanners have added capabilities such as portability, wireless functionality, and cloud computing. These features have made data collection easier: for example, the emergence of AI powered handheld scanners has made it easier to capture data in intricate environments. In addition, storing data on cloud platforms allows team members to work with the models from different locations, thus enhancing collaboration and teamwork. The widespread application of the technology means that 3D laser scanning will become even more useful across varying industries and fields. The market is expected to grow at a compound annual growth rate (CAGR) of 15.5% between 2023 and 2030.

How to Choose the Best Laser for 3D Printing?

- Material Compatibility – Confirm that the laser is appropriate for the materials you intend to work with such as metals, polymers, or ceramics. Certain lasers may have specific wavelength or power requirements to function optimally.

- Precision and Resolution – Make sure to choose a laser that delivers the desired accuracy to attain the level of detail required in your prints. This aspect is critical with complex shapes or patterns.

- Power Output – Choose a laser with sufficient power to process the materials efficiently while maintaining their quality and durability. Tougher materials require stronger lasers.

- Reliability and Longevity – Select a laser that provides consistency and reliable performance over time to ensure long-term operational stability w in these areas.

- Cost and Maintenance – Evaluate the budget alongside maintenance costs. Some higher-end lasers might come with greater operational costs, but offer longer lifespans, thus great value.

Factors to Consider: Optimization and Accuracy

In the case of lasers, precision and efficiency are two key attributes; this is more pertinent in the case of sensitive and precise tasks. An optimal efficiency laser mitigates energy waste, cutting down on costs. For instance, modern fiber lasers are said to surpass traditional CO2 lasers by converting up to 70% of the input energy to output light, while the oldest would only achieve 10-20% conversion and output. In the long run, efficiency translates to reduced energy consumption and lower production costs.

Equally important is precision in the production processes of components of sensitive devices such as manufacturing equipment, medical instruments, and electronics. Laser Systems are advanced enough to achieve microns within cutting accuracy such that intricate features and components may be fabricated. Some recent market research indicates, with the use of real-time monitoring, operational error reduction systems powered by AI, and recalibration on the fly, novel laser technologies have AI-based self-correction integrated making them more precise with less error and better value across high demand industries. The increased functionality adds quality and productivity, resulting in advanced lasers being unavoidable for industries that are highly sought after.

Comparing Laser Types for 3D Printing

The primary laser types used in 3D printing are fiber lasers, CO2 lasers, diode lasers, and solid-state lasers.

| Laser Type | Wavelength | Power Output | Precision | Cost |

|---|---|---|---|---|

| Fiber Laser | ~1.07 µm | High | High | High |

| CO2 Laser | ~10.6 µm | Medium | Moderate | Medium |

| Diode Laser | Various | Low | Low | Low |

| Solid-State Laser | ~0.5-1.2 µm | High | High | High |

Assessing the Laser Cutting Capabilities for 3D Printers

While selecting a laser for 3D printing, the most important factors to take into account are accuracy, financial implications, and whether it works with the materials needed. Fiber lasers, while expensive, offer sharp precision and are appropriate for industrial-grade work that requires precision details. CO2 lasers offer moderate pricing and work across a variety of materials which makes them versatile. Diode lasers, on the other hand, are the cheapest option; however, their lower accuracy makes them only appropriate for simple tasks. Like fiber lasers, solid state lasers are high powered and precise which makes them expensive, but best fit for very specialized advanced tasks.

What Are the Different Types of Laser Cutting Machines?

- Fiber Laser Machines: These specialize in cutting precision metals and hard materials due to their powerful and precise nature.

- CO2 Laser Machines: They are widely used for cutting wood, acrylics, and plastics because of their versatility and moderate price.

- Diode Laser Machines: Least expensive of the bunch, these are only useful in basic tasks that do not require precision.

- Solid State Laser Machines: Specialized and advanced applications requiring high accuracy and power are best suited for these machines.

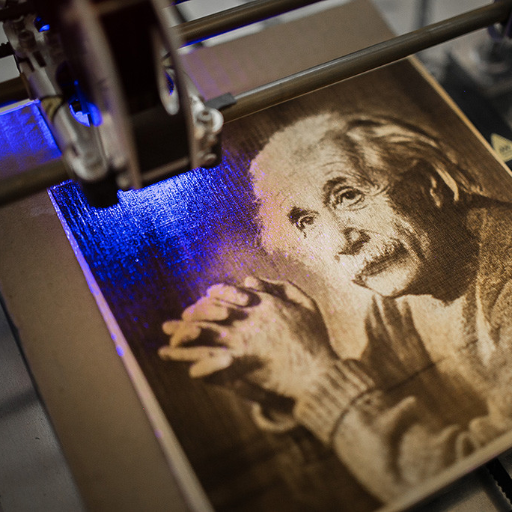

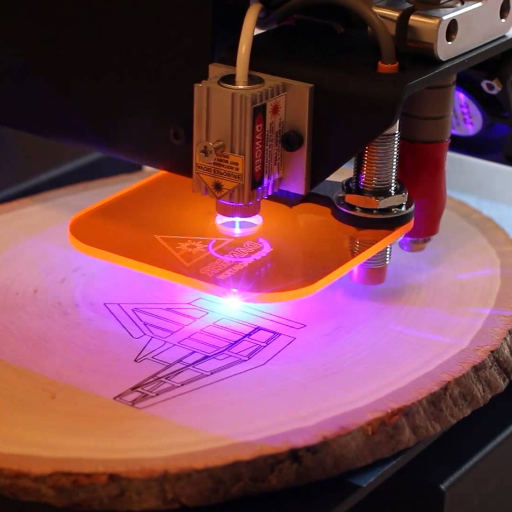

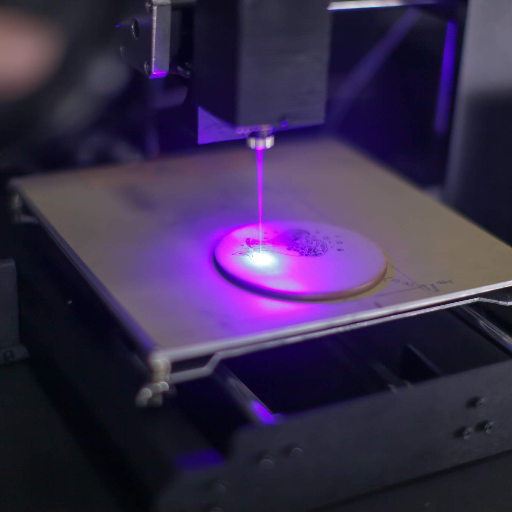

Exploring Laser Engraving Machines

Laser engraving machines use a laser beam to focus and strip away materials from the object’s surface to create a design or pattern. They work efficiently with a variety of materials such as wood, metal, glass, and plastic. The main types of laser engraving machines include fiber, CO2, and diode lasers, each best suited for different materials and applications. The selection of the machine is based upon the material to be engraved, the level of accuracy required, and the intricacy of the design.

Comprehending Complete Spectrum Laser Systems

The systems compete in the market as Full Spectrum Laser (FSL) systems, which serve many functions such as laser engraving, cutting, and marking due to their versatile and innovative nature. FSL machines are well known for their precision and reliability. They are advanced technology machines fit for amateurs and industrial-scale operations alike.

Users can tackle many diverse projects because these systems have a dual laser or hybrid capabilities that enable them to work on various materials such as wood, acrylic, textiles, metals, and glass. FSL’s Muse series, for instance, accurately cuts and engraves through precise real-time alignment camera and autofocus abilities which allows minimal error precision.

For projects on a hobbyist level, users can enjoy a 40W CO2 laser and switch to demanding industrial grade models on above 150W for heavy duty tasks. All that with customizable power options. According to recent information, their RetinaEngrave software has also been shown to maintain high-engraving speeds for complex vector and raster designs of 500 mm/s on some models.

Professionally crafted with user-friendliness in mind, Full Spectrum Laser systems prioritize safety as well. Model and equipment types vary, but each comes optimized füme removal systems, protective screens against harmful particulates, and even intuitive navigation touch screens. This makes FSL equipment perfect for professionals as well as for educational institutions or workshop settings.

Full Spectrum Laser machines are versatile and are modelled as a compact desktop set up or industrial-grade systems. This brand is globally accepted as a high performing and scalable solution when it comes to customization for personal or professional engraving projects. FSL is a leader in the laser system industry due to their cutting-edge technology along with the user’s needs-focused design.

Advantages Offered by Portable Laser Cutters

The portable size offers several advantages from a user’s perspective. Now, precision cutting and engraving can be done not only in workshops and classrooms, but also at client sites. Between 2022-2030, the market value of portable laser cut machines is expected to grow at a CAGR of 9.1%, estimated to be worth $10.9 billion by 2030. Such figures indicate a high demand in industries focusing on manufacturing, automotive, electronics, and even design.

The versatility and efficiency of modern laser cutters is obviosly for everyone to see, with them being portable, having built in cooling fans, wi fi functions, and even processing data at high speeds. In addition to this ease and comfort, they also come equipped with simple to understand software, that can be utilized with equal ease by professionals as well as laymen. Perhaps, the best part is that the machines are able to seamlessly work with different materials such as wood, leather, metals, glass and even acrylic.

The last point I shall make today regards cost. Tim and resources are always tight and these devices multifaceted capabilities, allows them to be used in place of rather friendlier services. Compact and multifunctional, these devices are turning out to be great tools for many businesses and amature crafters alike.

How Does 3D Laser Engraving Enhance Manufacturing?

3D laser engraving is transforming manufacturing by enabling the fine-tuned and complex designs to be etched on materials with great accuracy. It allows products to be replicated consistently, lessens production time, and reduces material waste. Due to its ability to customize and add details of great precision, the technology is invaluable in aerospace, automotive and consumer industries.

Precision and Accuracy in Laser Engraving

With regard to the material and system in use, 3D laser engraving is accurate to within 10 microns. Some advanced laser systems achieve accuracy of ±0.01 mm, which is often used in aerospace or medical device manufacturing. The latest reports state the laser engraving industry value reached $2.9 billion in 2022 and anticipated growth of 5.86% CAGR from 2023-2030. This is a direct result of increasing demand for technology that provides detailed engraving with high precision and reproducibility, low human intervention.

Moreover, contemporary laser engraving machines come equipped with AI smart controls and IoT devices for remote supervision and improvement of processes in real-time. This is particularly beneficial for stream automated processes which require little to no idle time and promise high volumes of production at a set precision rate. Such industries as microelectronics depend greatly on this accuracy which means that the engraved circuits and parts must have their dimensions measured in micrometers. This observation underlines the importance of 3D laser engraving in transforming manufacturing processes to evolving requirements and technological benchmarks.

The Effect of 3D Laser Technology on Surface Texture

3D laser engraving technology specializes in the modification and control of diverse material surfaces that need texture change. Changes in the surface layer of materials with regard to their functions, life span, and appearance are achieved through the application of high-accuracy laser beams. As per the estimates, adoption of 3D laser engraving and cutting technologies will drive the growth of the laser processing market across the globe at a compound annual growth rate (CAGR) of 8.6% between 2023 and 2030.

One of the distinct features is the reduction of friction through micro-texturing. For example, laser-textured surfaces on engine components in the automotive industry improves performance efficiency. Studies show energy losses in mechanical systems achieving micro-texturing with 3D laser engraving have the potential to improve efficiency by 15%.

Also, customization on complex shapes and features is made possible with new advancement in 3D laser systems. This has proven to be advantageous in the medical device industry for manufacturing as the implants and instruments require stringent regulatory compliance. One example is the texture lasers used orthopedic implants which enhances the bonding surfaces which incries the probability of successful surgeries.

These advances also demonstrate why innovations in 3D laser engraving should be considered and leveraged as an innovation surface properties can be manipulated seamlessly reshaping the surfaces with precision allow for progression in various industries.

The Focus on Improvement of Engraving Machines

The impact of modern technologies like laser engraving and fibers have advanced in the last few years. Implementation of IoT and AI neural networks offer enhanced efficiency in image capturing and recognition which functionality systems and puts image capturing and printing on a new level. Advanced engraving laser systems have been manufactured and ensures every industry achieves smooth functionality, accuracy, and performed standardized operations. Medical and precision parts industry are known to require utmost cautiousness with devices and their components, hence the imprinted styles using laser blades is far more reliable

As per the latest market analysis, the global laser engraving industry reached an estimated value of $2.8 billion in 2022, with projections estimating a CAGR of 6.5% from 2023 to 2030. The aerospace and automotive sectors remain the foremost utilizers, employing laser engraving for micro-engraving parts and improving product traceability.

Moreover, newer technologies such as 3D laser engraving machines enable the multi-faceted engraving of metals, polymers, and even ceramics. For instance, some orthopedic manufacturers have reported over 20% improvements in surgical outcomes due to enhanced texturing compatible with human tissues resulting from bespoke 3D laser engraving system.

Software improvements have also simplified the engraving workflow, allowing for more comprehensive pre-production simulations. Innovations within the industry are always welcome, and these advancements can reduce waste and production times by around 30% compared to conventional approaches.

Why is 3D Laser Technology Considered Versatile?

The 3D laser works with metals, plastics, ceramics, and other materials. Due to this capability, it is multifunctional and can cut, engrave, mark, and weld with great accuracy. Furthermore, as a result of it being a non-contact process, the 3D laser undergoes minimal damage to parts, which makes it useful in sensitive operations. Because it can be used in delicate applications without damage, the 3D laser finds applicability in many sectors like healthcare, aerospace, and manufacturing.

Exploring New Possibilities with 3D Lasers

Technological innovations are reshaping industries and facilitating new levels of accuracy and adaptability. Continued improvements and advancements in this technology help further enhance laser’s potential. As reported in the market research, the global market for 3D laser scanners is expected to reach $8.55 by 2025 with 8.1% CAGR. Its adoption in construction, automotive, and healthcare industries drives this growth.

One important benefit offered by 3D lasers is the model creation of exemplary detail which can be easily achieved. As an instance, in the construction industry, 3D maps and site layouts are created using these lasers. The automotive industry uses 3D laser scanners for reverse engineering and quality assurance in laser checks of intricate parts. In the medical field, 3D lasers are used in making prosthetic devices and dental appliances to assist in ensuring these products are made for specific individuals.

Developments in 3D laser software have made it possible to merge them into CAD systems, allowing designers and engineers to automate parts of their work. Also, 3D laser systems now incorporate AI and machine learning, which offers expanded capabilities such as predictive maintenance and accelerated data processing. All these technologies showcase how modern 3D lasers are crucial in many areas with boundless potentials towards advancement.

Uses other than 3D Laser Printing and Cutting

In my opinion, the scope of 3D laser systems goes far beyond the boundaries of conventional 3D printing and cutting. They are currently revolutionizing fields such as medical imaging, which require meticulous scanning, as well as in environmental monitoring for precise contaminant detection and accuracy in mapping. I have also observed increased use in artistic and architectural restoration, where lasers assist in the analysis and preservation of intricate artworks and structures. These applications certainly demonstrate how remarkable this technology is.

Benefits of Lightweight and Portable Designs

The advent of portable devices and equipment has greatly enhanced their convenience and usability for diverse tasks and in various fields. As per the contemporary research, the worldwide market for portable electronics is expected to increase at a compound annual growth rate (CAGR) of 11.3 % from 2023 to 2030, as a result of advancements in materials and the miniaturization of components.

One of the most areas this trend stands out is in healthcare. For instance, the modern portable ultrasound machines chemotherapy have shrunk in weight from a burdensome 200 pounds to an easily transportable under 10 pounds. Additionally, portable air quality sensors aiding city planners and environmentalists in combating pollution streams offer high precision, real-time data with less than 3 watts of power.

The contemporary consumer technology benefits from the improved weight allowance with mobility. Tablet and laptop handheld computers are now slim without performance tradeoffs. Popular consumer laptops released in 2023 offer high resolution displays, powerful processors, and extended battery life innovation while weighing just 2.2 pounds. All these features are essential for professionals and students.

In the end, lightweight and portable designs broaden the audience modern technology can reach.

Reference sources

- 3D Laser Nanoprinting of Functional Materials (Liu et al., 2023)

- Key Findings:

- 3D laser nanoprinting allows maskless fabrication of 3D nanostructures at a resolution beyond the optical diffraction limit, endowing the printed structures with novel physical, chemical, or mechanical properties.

- One strategy is to use the 3D-printed polymer structures as skeletons for functional material deposition, while another is to mix the functional components with the photocurable molecules and print the nanocomposites.

- Several laser nanoprinting techniques beyond photopolymerization have also been developed.

- Methodology:

- The review summarizes the cutting-edge technical innovations in 3D laser nanoprinting and highlights a few examples showing exciting applications in magnetic microrobots, photonics, and optoelectronics.

- Key Findings:

- Experiment and Application of NATM Tunnel Deformation Monitoring Based on 3D Laser Scanning (Hu et al., 2023)

- Key Findings:

- Tunnel deformation monitoring based on 3D laser scanning technology can better reflect the evolution of the tunnel full-space deformation field under certain environmental conditions and can provide an effective safety warning for tunnel construction.

- The Kriging filtering algorithm can efficiently identify and extract the tunnel profile visualization data and accurately obtain the tunnel deformation, with the measurement results in good agreement with those obtained by using traditional monitoring methods.

- Methodology:

- An improved Kriging filtering algorithm is proposed to optimize the point cloud grid filtering and extract the deformation information of the measuring points on the surface of the tunnel lining.

- The deformation data obtained from the test are compared with the data measured by traditional methods to validate the proposed technology.

- Key Findings:

- Recent Advances in Multi‐Photon 3D Laser Printing: Active Materials and Applications (Mainik et al., 2023)

- Key Findings:

- The development and commercialization of photocurable inks for multi-photon 3D laser printing have expanded rapidly, enabling a new degree of control in the printed systems through the transition from static to active printable materials (4D microprinting).

- Recent progress and the crucial role of active materials, including liquid crystalline elastomers, hydrogels, shape memory polymers, and composites, are highlighted in the fields of microrobotics, optics and photonics, microfluidics, and life sciences.

- Methodology:

- The review focuses on four primary application areas and addresses ongoing challenges and future prospects in the different fields.

- Key Findings:

Frequently Asked Questions (FAQs)

Q: What a 3 Dlaser engraver and explain it’s functionality.

A: A 3D laser engraver is a piece of equipment that applies laser technology to mark three dimensional objects. It uses a laser beam that is a scanned onto the surface of a material and is delivered like sliced data in 3D. The laser head traces the path or spiral of the material contours which results in perfect engraving of the design.

Q: In what ways does a 3D differ from a 2D laser engraver.

A: While a 3D laser engraver can engrave on three dimensional surfaces, flat materials are the only type of object that a 2D laser engraver is capable of working on. The 3D version employs sophisticated 3D interpretation software to read 3D data, circumventing the limitations of 3D shapes and surfaces hence enabling deeply precise engravings on intricate shapes.

Q: List all materials that can beengraved through 3D laser engravers.

A: A 3D laser engraver wood, metal, plastic, glass, and even polished materials. Other than being versatile, it also serves as a cost efficient tool because of the diverse options it can engrave.

Q: What are the advantages of using 3D Laser Engraver?

A: Advantages entail efficient productivity, precise graphics reproduction, capability to handle intricate three-dimensional designs, and rapid engraving speed. In addition, the machine is sturdy and durable, which makes it a cost-efficient asset for corporations.

Q: Are beginners able to operate a 3D laser engraver with ease?

A: Absolutely. Most new models of 3D laser engravers are equipped with intuitive interfaces and software that make them simple to operate. Users can access pre-established patterns as well as instructional guides that walk through the design creation process.

Q: Is a 3D laser engraver suitable for mass production?

A: Yes, a 3D laser engraver excels in mass production because of their efficiency and quick turnaround time. They rank among the fastest engravers of large volumes of items with precision and uniformity.

Q: What steps are involved in servicing a 3D laser engraver?

A: Servicing a 3D laser engraver entails cleaning the head and other crucial parts of the engraver on a regular basis. It is also critical to check the laser system for precise alignment and calibration so that he quality of the engraving is maintained. Routine servicing aids in achieving optimum performance for enduring functionality.

Q: What criteria do I need to pay attention to while selecting the best 3D Laser engraver?

A: In addition to the materials that will be engraved upon, engraving area dimensions, machine precision and speed, cloth rotary feature for cylindrical items, and more are all very important considerations. Adhering to your own preferences will best 3D engravings.

Q: Is engraver 3D laser capable of also performing cutting functions?

A: In addition to engraving, the majority of 3D laser engravers are capable of cutting materials, making them versatile for many applications. The switching ability between engraving and cutting increases their utilitarian value.

Q: What rules or guidelies any user of 3D laser should observe to be on the safe side?

A: Use laser protective goggles, ensure ventilation in the workplace to avoid toxic fumes while working, operate the 3D laser engraver strictly within the limits of its manual recommendations, and maintain adequate distance from the laser head during operation.

- Understanding the Melting Point of Polypropylene: A Comprehensive Guide

- The Fascinating World of Sodium Bicarbonate: Understanding Its Melting Point

- Understanding the Difference Between CNC and VMC Milling Machines: Complete Comparison Guide

- The Art of Precision: Mastering the Wood Laser Engraving Machine